Plastic Mould Steel

-

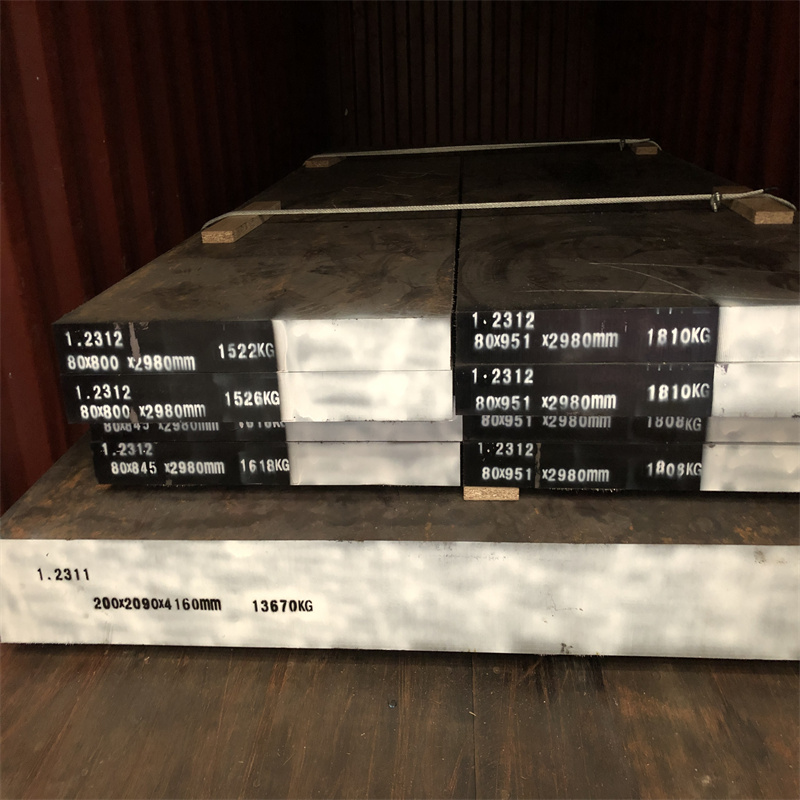

1.2312 Plastic Mold Steel

DIN 1.2312 steel has maintained high quality and low sulfur content since its production. Therefore, the material has good polishing and photo-etching properties, good processing performance, high purity, excellent uniformity and reliable uniform hardness. The characteristics of DIN 1.2312 tool steel are: the material hardness of large cross-section is relatively uniform and balanced; excellent cutting performance; high compressive strength; wear resistance; good corrosion resistance; suitable for making large plastic molds

Email Details -

Hot

1.2316 Plastic Mold Steel

1.2316 steel is mainly used for plastic injection molds, in connection with chemically aggressive and acidic plastics such as thermoplastics and for PVC-arminoplastics, extrusion tools, compressor parts and for special machine parts in the food industry.Our company are 1.2316 tool steel suppliers

Email Details -

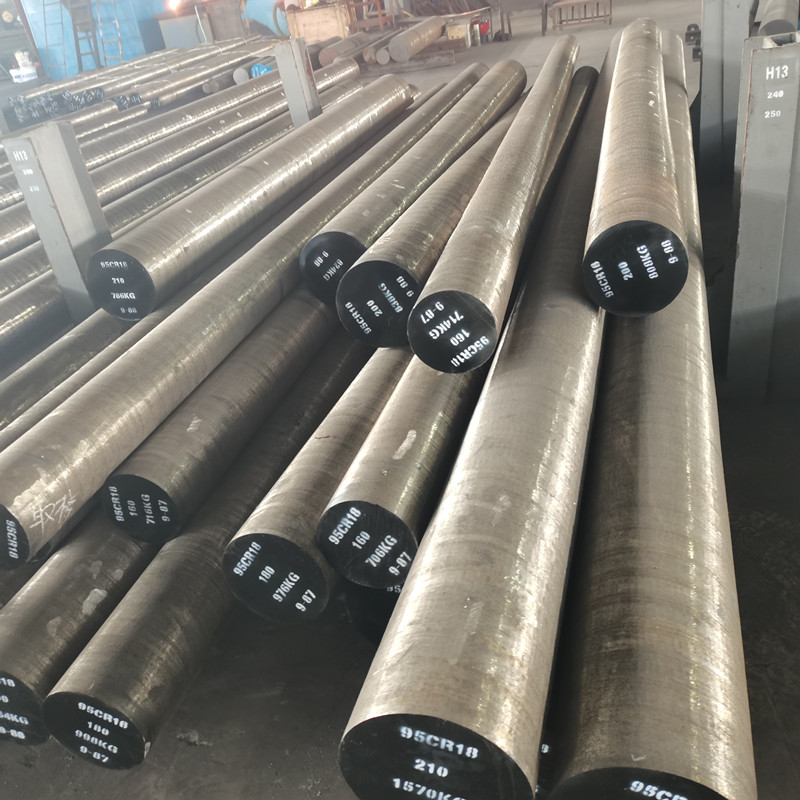

Plastic Mould Steel 95Cr18

95Cr18 Plastic Mould Steel is used for stainless slicing, mechanical cutting tools, cutting knives, scalpels and high wear-resistant equipment parts (such as ball screws).

Email Details -

GB 3Cr2MnNiMo Plastic Mould Structural Steel

3Cr2MnNiMo Steel is a plastic mold steel widely used in the world. It has good comprehensive mechanical properties and high hardenability. It can make large-section steel have a more uniform hardness distribution after quenching and tempering, and has good polishing performance and smoothness.Our company provides 3Cr2MnNiMo Round Bar Steel and 3Cr2MnNiMo tool steel plate

Email Details -

1.2738 Plastic Mold Steel

1.2738 steel After special processing, high standards of trace purity are obtained.

Email Details

- Excellent nitriding performance, good wear resistance, excellent photographic engraving/polishing performance

and good weldability

-Applications: Large and medium-sized molds in the automotive and food industries, rubber molding molds,

Molds for compression molding of thermoset composites

(SMC sheet molding compound, BMC bulk molding compound) and mold holder

- Extrusion: PVC substrates and calibrators, extrusion machinery parts

The corresponding foreign brand of 1.2738 is P20+Ni 、718HH、3Cr2NiMo -

P20 Plastic Mold Steel

P20 steel is American AISI standard pre-hardened plastic mold steel. P20 tool steel has good machining performance, excellent polishing performance, certain toughness, and can be carburized. After carburizing and quenching, the surface hardness can reach 65HRC, and has high thermal resistance. Hardness and wear resistance.

Email Details -

AISI P20+S Plastic Mould Steel

AISI P20+S steel is a high-quality low-alloy wear-resistant steel that is widely used in the manufacturing of various wear-resistant precision mold tools and plastic moulding. AISI P20+S has good chemical stability and corrosion resistance, which can effectively prevent rust and corrosion.P20+S special steel is a high-strength alloy tool steel,and The corresponding foreign brand of AISI P20+S is DIN 1.2312、40CrMnMoS8-6.

Email Details -

1.2083 Plastic Mold Steel

DIN 1.2083 steel mainly applies to production of PVC mold, wear resistance and fillers, including hot hard plastic molds, long life molds, production of optical product components, such as cameras and solar lenses, medical containers, laser CDs, etc.

Email Details

Sample testing of 1.2083 steel will be done on each batch as per the standard,1.2083 steel will be not only done by mill itself, also will be done by third party. In this way, the quality can get double assurance. -

Hot

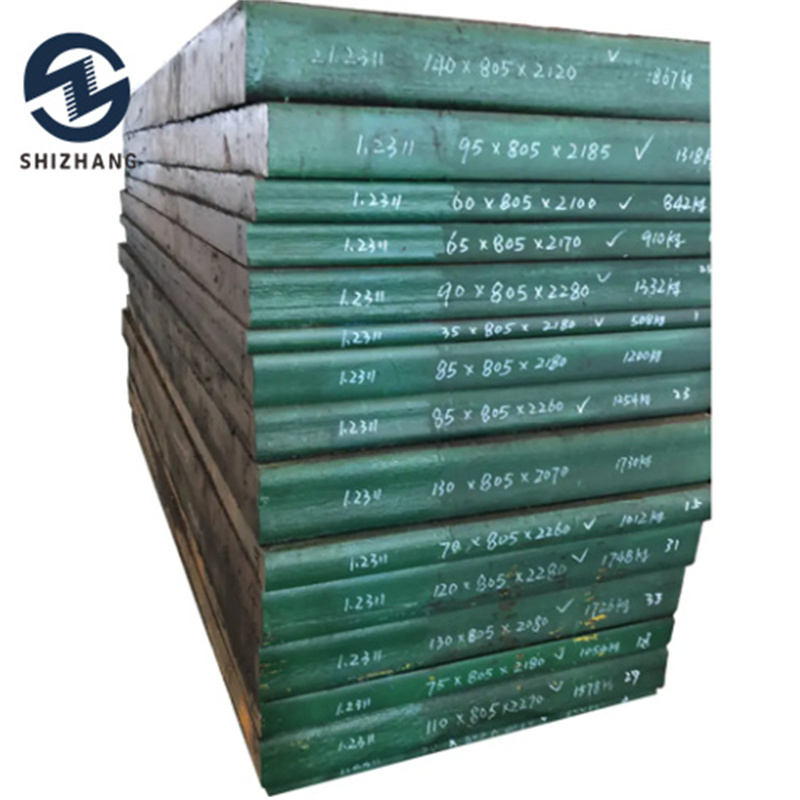

1.2311 Plastic Mold Steel

German mold steel 1.2311 . This steel is produced through an "ultra-pure" process and is pre-hardened. 1.2311 steel shows a high degree of micro-purity and excellent homogeneous structure, excellent polishability and photo-etching properties. After heat treatment, DIN 1.2311 tool steel has good processing and polishing properties, can be nitrided, and is suitable for surface treatments such as chrome plating. The material has uniform hardness (up to 400mm thick), good toughness, and good machining performance

Email Details