tool steel

-

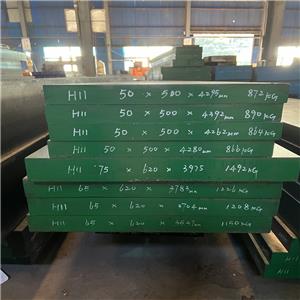

AISI H11 Hot Work Tool Steel

AISI H11 (DIN 1.2343) is one of the hot work chromium type tool steels belong to ASTM A681 standard. It has good strength in high temperature, excellent toughness and ductility in all z directions, excellent hardenability, and a high level of thermal shock and thermal fatigue resistance. AISI H11 steel can be deeply hardened by heat treatment and air quenching.

Email Details -

AISI H13 Tool Steel

AISI H13 tool steel is characterized by its high hardness, wear resistance, toughness, and corrosion resistance. AISI H13 steel can withstand high temperature and high pressure loads. AISI H13 steel can reduce the tooling wear and improve production efficiency.

Email Details -

Cold Work Die Steel A2

The hardness of aisi a2 tool steel is higher than SKD11 after heat treatment. It can reach a high hardness of 60-62HRC after tempering at high temperature (500-520℃), and exceeds SKD11 in strength. aisi a2 tool steel is an air-cooled hardenable chromium steel with excellent toughness and high wear resistance. Small heat treatment deformation.Our company provides aisi a2 steel Round Bar or aisi a2 steel plates etc.

Email Details -

H13 Hot Work Die Steel

AISI H13 tool steel is characterized by its high hardness, wear resistance, toughness, and corrosion resistance. AISI H13 steel can withstand high temperature and high pressure loads. AISI H13 steel can reduce the tooling wear and improve production efficiency.

Email Details -

H11 Hot Work Tool Steel

AISI H11 die steel is often used for highly stressed structural parts such as aircraft landing gear. H11 steel resistssoftening at temperatures up to 537°C while retaining good ductility and toughness even atstrength levels on the order of 275 ksi. Tools for hot forging of light metal. Pressure die castingtools. Dies, mandrels, punchers, knives, moulds. This grade can be water cooled.

Email Details -

DIN 1.2343(X37CrMoV5-1)Hot Worked Mold Steel

H11/1.2343 tool steel is a high-strength, high-toughness hot-work mold steel with excellent heat resistance and hardness, widely used in manufacturing high-quality molds, mold components, and tools . Compared to other types of steel, H11 tool steel exhibits superior comprehensive performance, especially at high temperatures, maintaining its strength and toughness even below 600℃ [High Temperature Performance]. Its chemical composition includes chromium, molybdenum, and vanadium, which contribute to its high hardness and wear resistance. While H11/1.2343 tool steel can undergo heat treatment processes like quenching and tempering to enhance its hardness and strength, it may impact its plasticity [Heat Treatment & Plasticity]. Overall, H11 steel is particularly suitable for manufacturing molds requiring high precision and complexity due to its superior deformation ability and workability [Suitability for Complex Molds] .

Email Details -

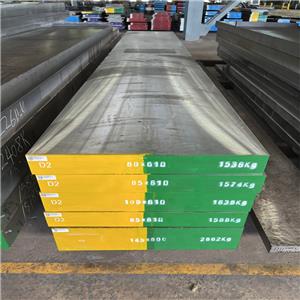

D2 Cold Work Die Steel

AISI d2 tool steel is used for metal stamping dies, drawing dies, stainless steel punching dies, high hardness punching dies, cutting dies, thread rolling dies, hardware parts manufacturing, machinery manufacturing, etc.The corresponding foreign brand of aisi d2 metal is 1.2379 steel、Cr12Mo1V1 steel、JIS SKD11

Email Details -

Hot

H11 Hot Work Die Steel

AISI H11 tool steel is often used for highly stressed structural parts such as aircraft landing gear. AISI H11 tool steel resistssoftening at temperatures up to 537°C while retaining good ductility and toughness even atstrength levels on the order of 275 ksi. Tools for hot forging of light metal. Pressure die castingtools. Dies, mandrels, punchers, knives, moulds.The corresponding trademark of AISI H11 steel in other countries is X37CrMoV5、1.2343、GB 4Cr5MoSiV

Email Details -

D3 Cold Work Die Steel

D3 is suitable for making dies and punches, cold shear knives, drill sleeves, gauges, wire drawing dies, etc. that are subject to less impact load and require higher wear resistance.The corresponding foreign brand of D3 is JIS SKD1、DIN 1.2080、Cr12 steel

Email Details