DIN 1.2343(X37CrMoV5-1)Hot Worked Mold Steel

H11/1.2343 tool steel is a high-strength, high-toughness hot-work mold steel with excellent heat resistance and hardness, widely used in manufacturing high-quality molds, mold components, and tools . Compared to other types of steel, H11 tool steel exhibits superior comprehensive performance, especially at high temperatures, maintaining its strength and toughness even below 600℃ [High Temperature Performance]. Its chemical composition includes chromium, molybdenum, and vanadium, which contribute to its high hardness and wear resistance. While H11/1.2343 tool steel can undergo heat treatment processes like quenching and tempering to enhance its hardness and strength, it may impact its plasticity [Heat Treatment & Plasticity]. Overall, H11 steel is particularly suitable for manufacturing molds requiring high precision and complexity due to its superior deformation ability and workability [Suitability for Complex Molds] .

Product Name: HOT WORK TOOL STEEL---AISI H11

Similar steel grades:

AISI | H11 |

W. Nr. | 1.2343 |

DIN | X37CrMoV5 |

JIS | - |

GB/T1299-2000 | 4Cr5MoSiV |

ISO | X37CrMoV5-1 |

Principal Feature:

AISI H11 Hot work tool steel is a 5% chromium hot work steel that is characterized by excellent impact toughness. It contains less vanadium than the widely-used H13 hot work tool steel. H11 is a deep-hardening, air-hardening steel that exhibits minimal size change during heat treatment. It has good resistance to thermal fatigue cracking (heat checking) and excellent resistance to gross cracking and thermal shock when water cooled in service. H11 is recommended for hot tooling applications where maximum resistance to cracking is required.

Typical Application:

H11 tool steel is typically applied in high-load hot work scenarios. It is well-suited for manufacturing high-speed hammer forging dies, aluminum and magnesium alloy hot forging dies, and black metal forging dies . Its applications also extend to hot work forging and extrusion dies, as well as helicopter rotor blades, where high toughness and hardness are required . The steel's excellent resistance to thermal fatigue, good hot hardness, and excellent machinability make it a preferred choice in these applications . To enhance its properties for longer life and higher design accuracy, H11 steel can undergo various heat treatment processes .

Heat Treatment:

Forge: at 1050℃-1095℃ Cool slowly and anneal then.

Annealing: at 843℃-898℃ Cool slowly in furnace

Stress Relieving: heat slowly to 566-676℃, and then cool in still air.

Hardening: Preheat to 815 ℃ and then heat to 1010℃ and hold for 15 to 40 minutes. Air cool (air quench)

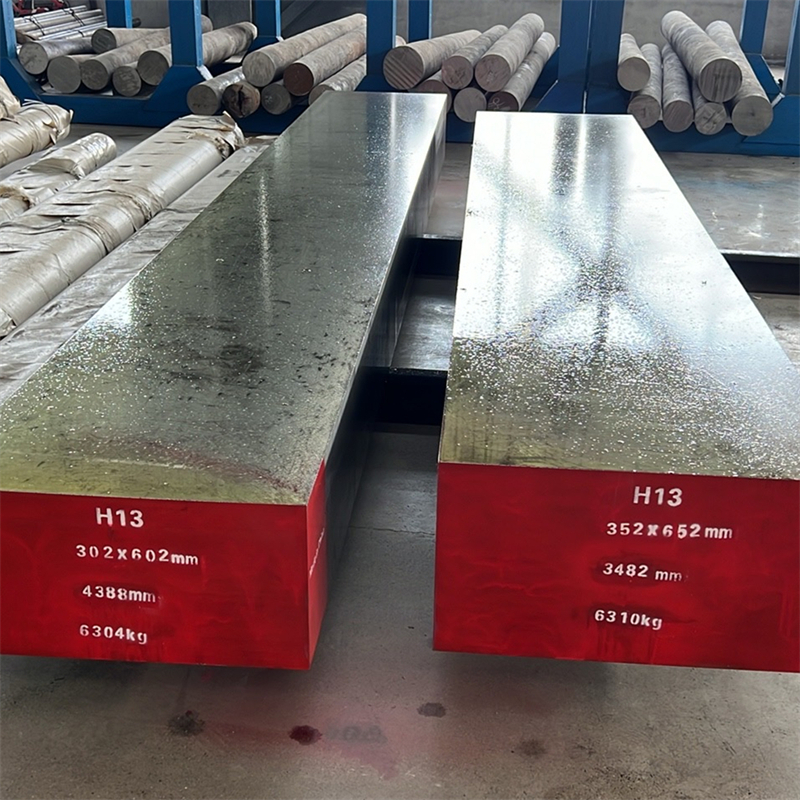

Size available:

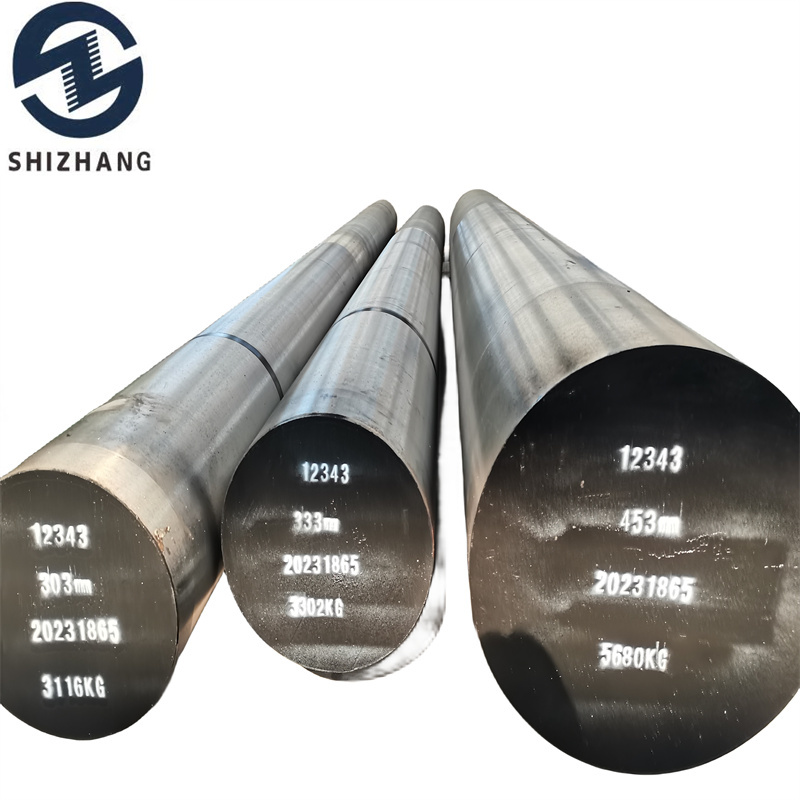

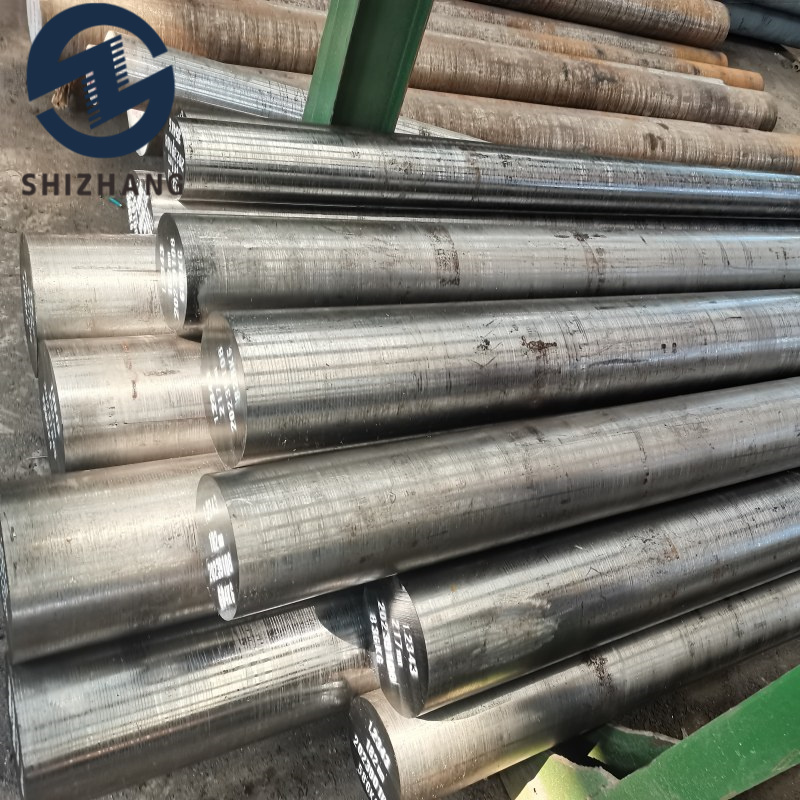

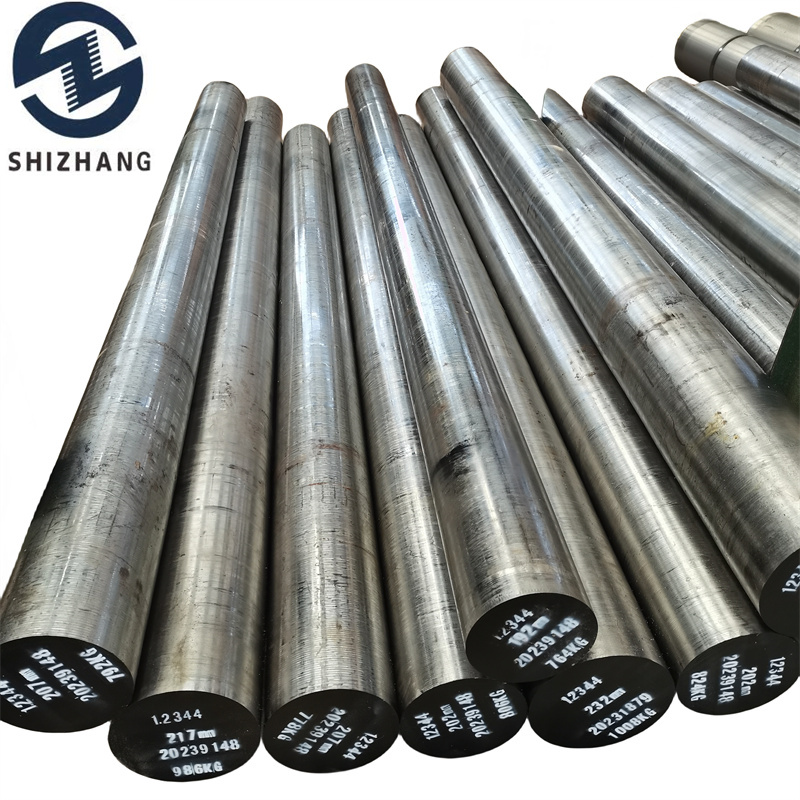

Bars | Turned | Dia20-800mm |

Black | Dia 20-800mm | |

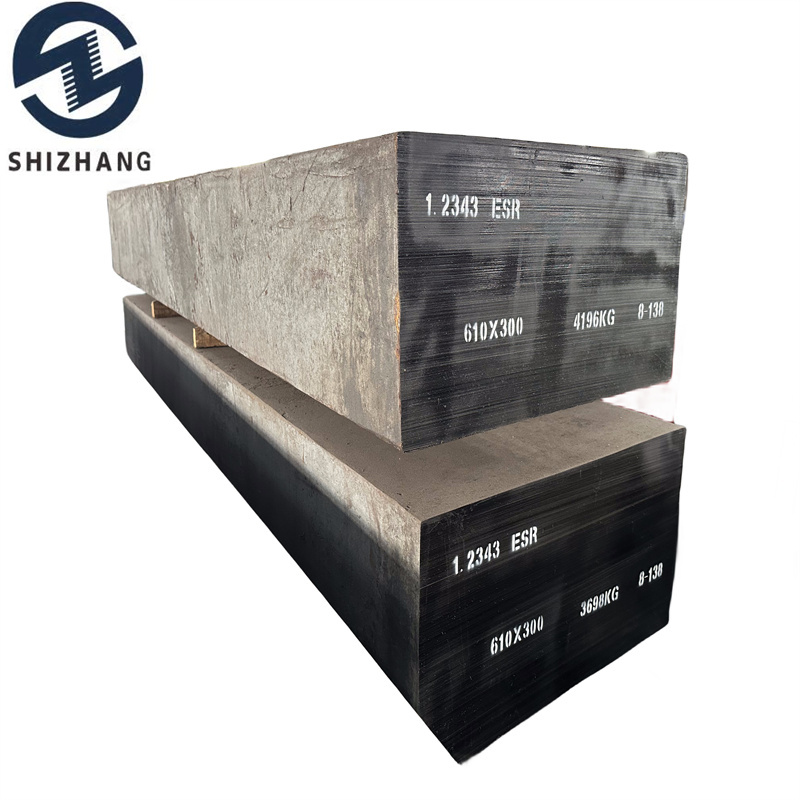

Flats | Milled | T: 8-400 W: 210-610mm |

Black | T: 8-400 W: 210-610mm |