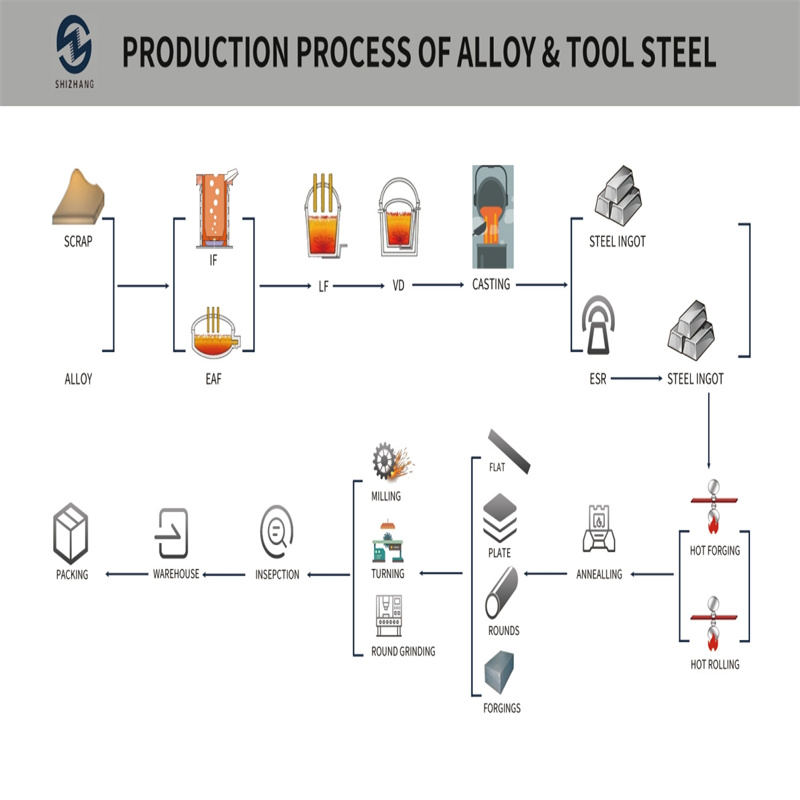

Production Process

The production process of mold steel is quite complex, and each stage must be strictly controlled to ensure the final product's quality. Below is a more detailed description of the production process of mold steel:

1. Smelting

Smelting is the initial step in the production of mold steel, where raw materials are melted and alloying elements are added to adjust the composition and performance of the steel. Common smelting equipment includes:

Electric Arc Furnace (EAF): Mainly used for melting scrap steel. The scrap is melted by the high temperature of the electric arc, and various alloying elements are added as needed.

Vacuum Induction Melting (VIM): Steel is melted in a vacuum environment, effectively removing gases and impurities from the molten steel, improving its purity, and ensuring uniform distribution of alloying elements. This method is used to produce high-quality mold steel.

Electroslag Remelting (ESR): In this process, molten steel is remelted through electrical current in a slag bath, which helps eliminate impurities and refine the grain structure, resulting in a more uniform and high-quality product.

During smelting, various alloying elements (such as chromium, molybdenum, tungsten, vanadium, nickel, cobalt, etc.) are added according to the required steel type and performance characteristics. These alloying elements influence properties such as hardness, wear resistance, toughness, and thermal stability.

2. Casting

After smelting, the molten steel is cast into ingots or billets, typically using the following methods:

Ingot Casting: The molten steel is poured into molds to cool and form ingot-shaped or block-shaped mold steel. Ingot casting is typically used for larger sizes, which will later undergo forging.

Continuous Casting: The molten steel is cast continuously into billets, providing better uniformity and fewer defects. This method is suitable for large-scale production and precise control of the steel’s properties.

During the casting process, cooling speed must be strictly controlled. Too fast or too slow cooling may lead to defects such as porosity or cracks. Proper cooling control directly impacts the steel's microstructure and physical properties.

3. Forging

Forging is the process of heating the cast steel ingot to high temperatures and applying mechanical pressure to deform it plastically, further improving its internal structure and mechanical properties.

Heating: The steel ingot is first heated to a forging temperature (typically 1000-1200°C), ensuring the material is sufficiently plastic for shaping.

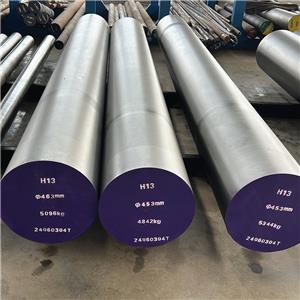

Forging: The ingot is subjected to pressure from a forging machine, which compresses and elongates it into the required shape, such as round bars, square bars, etc. During forging, the steel's grain structure is refined, leading to increased strength and toughness.

Eliminating Internal Defects: Forging also helps remove internal defects formed during casting, such as gas bubbles or inclusions, improving the steel’s density and uniformity.

After forging, the mold steel undergoes significant improvements in both macro and microstructure, with more uniform grain size and higher tensile strength.

4. Heat Treatment

Heat treatment is a critical step in mold steel production. The goal is to adjust the steel's microstructure to enhance its hardness, wear resistance, and toughness. Common heat treatment processes include:

Annealing: Annealing involves heating the steel to a specific temperature and then cooling it slowly to eliminate internal stresses induced during forging, making the material’s structure more uniform and reducing hardness to improve machinability.

Normalizing: Similar to annealing but with faster cooling, typically using air. Normalizing enhances the steel's mechanical properties, particularly tensile strength and hardness.

Quenching: The steel is heated to its austenitizing temperature and then rapidly cooled (usually in water or oil) to form martensite. Quenching significantly increases the steel's hardness but may also make it brittle. To improve toughness, a subsequent tempering process is usually needed.

Tempering: After quenching, the steel is extremely hard but also brittle. Tempering is performed by reheating the steel to a lower temperature to reduce hardness while improving toughness and wear resistance. The specific tempering temperature and time are crucial for determining the final performance.

5. Machining

After heat treatment, mold steel is further processed through machining to ensure that its shape, size, and surface quality meet the required specifications. Common machining processes include:

Cutting: Steel is cut into the required size using methods like sawing, laser cutting, or plasma cutting.

Turning, Milling, Grinding: These processes are used to refine the shape of the mold steel, ensuring precise dimensions. Grinding, in particular, is used to improve surface quality, especially for high-hardness steels.

Drilling and Tapping: For some mold steels, drilling or tapping may be necessary to create cooling channels or holes for assembly.

6. Surface Treatment

To improve the wear resistance, corrosion resistance, or fatigue resistance of mold steel, additional surface treatments may be applied. Common surface treatments include:

Carburizing: The steel is heated and treated in a carbon-rich environment, allowing the surface to absorb carbon and form a hardened layer. Carburizing significantly improves wear resistance and is commonly used for high-wear mold applications.

Nitriding: Steel is heated in a nitrogen or ammonia gas environment to form a hardened nitride layer on the surface. This layer provides excellent hardness and corrosion resistance, making it ideal for mold steels that need high wear resistance and extended service life.

Electroplating or Coating: A metal or alloy layer (such as chromium or nickel) is applied to the steel's surface through electroplating or coating processes to enhance corrosion resistance and wear resistance.

7. Quality Inspection

Throughout the production process, mold steel undergoes strict quality control and testing. Common quality tests include:

Chemical Composition Analysis: Spectrometric or chemical methods are used to analyze the content of various alloying elements, ensuring the steel meets the required specifications.

Hardness Testing: Hardness testing is essential for evaluating the steel's wear resistance and deformation resistance. Common hardness tests include Brinell, Rockwell, and Vickers hardness tests.

Mechanical Property Testing: Includes tensile testing, impact testing, and fatigue testing to ensure the steel’s strength, toughness, and durability under working conditions.

Non-Destructive Testing (NDT): Methods like ultrasonic testing, magnetic particle inspection, and X-ray testing are used to detect internal cracks, porosity, or inclusions that could affect the steel's integrity.

8. Packaging and Delivery

After all machining and inspection processes are completed, the mold steel is packaged for delivery. Packaging is typically done using wooden crates, pallets, or other materials to protect the steel from damage during transport. Depending on customer requirements, the steel may be cut to different lengths, shapes, or surface treatments before being shipped.

Through the above complex production stages, the performance of mold steel is gradually optimized to meet various requirements such as high hardness, wear resistance, corrosion resistance, and toughness. Each step of the process, from smelting to packaging, is carefully controlled to ensure the final product is of high quality and meets customer needs.