Cold Work Die Steel

-

1.2601 Cold Work Die Steel

DIN1.2601 is a general-purpose cold work die steel with high wear resistance and toughness, high carbon and high chromium alloy tool steel and vacuum degassed refined steel. The steel is pure, has good hardenability and small quenching deformation. This steel has been softened by spheroidizing annealing and has good processability. The carbide particles are fine and uniform, so there is no need to worry about quenching cracking. Special additions of strengthening elements molybdenum and vanadium are required.The corresponding foreign brand of 1.2601 is Cr12MoV steel、AISI D5、JIS SKD10

Email Details -

Cold Work Die Steel 1.2436(X210CrW12)

DIN 1.2436 cold work die steel is German DIN standard extra high toughness chromium steel. Has extremely high wear resistance and edge retention capabilities. It is a widely used cold work die steel with high strength, good hardenability and good wear resistance, but poor impact toughness.Our company provides DIN 1.2436 steel plates and DIN 1.2436 Cold Work Mold Steel Round Bar

Email Details -

Cold Work Die Steel A2

The hardness of aisi a2 tool steel is higher than SKD11 after heat treatment. It can reach a high hardness of 60-62HRC after tempering at high temperature (500-520℃), and exceeds SKD11 in strength. aisi a2 tool steel is an air-cooled hardenable chromium steel with excellent toughness and high wear resistance. Small heat treatment deformation.Our company provides aisi a2 steel Round Bar or aisi a2 steel plates etc.

Email Details -

SKD11 Cold Work Die Steel

SKD11 is precision stamping mold steel、Ledeburitic 12% chrome steel, very high resistanceagainst abrasive and adhesive wear due to a highvolume of hard carbides in the steel matrix, goodtoughness,very gooddimensional stability, highcompressive strength, very good base material forPVD/CVD coating as well as nitriding due to itssecondary hardening properties.The corresponding grade of SKD11 is Equivalant to DIN 1.2379 、JIS SKD11 tool steel or GB Cr12Mo1V1

Email Details -

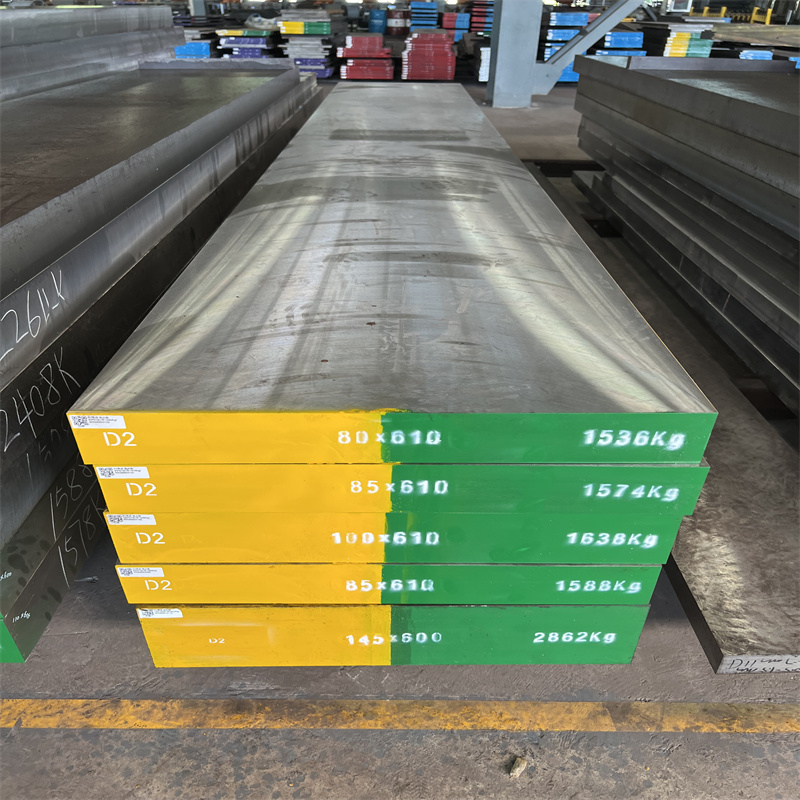

D2 Cold Work Die Steel

AISI d2 tool steel is used for metal stamping dies, drawing dies, stainless steel punching dies, high hardness punching dies, cutting dies, thread rolling dies, hardware parts manufacturing, machinery manufacturing, etc.The corresponding foreign brand of aisi d2 metal is 1.2379 steel、Cr12Mo1V1 steel、JIS SKD11

Email Details -

Hot

DIN 1.2379 Cold Work Die Steel

DIN 1.2379 steel is Ledeburitic 12% chrome steel, very high resistanceagainst abrasive and adhesive wear due to a highvolume of hard carbides in the steel matrix, goodtoughness,very gooddimensional stability, highcompressive strength, very good base material forPVD/CVD coating as well as nitriding due to itssecondary hardening properties.

Email Details -

D3 Cold Work Die Steel

D3 is suitable for making dies and punches, cold shear knives, drill sleeves, gauges, wire drawing dies, etc. that are subject to less impact load and require higher wear resistance.The corresponding foreign brand of D3 is JIS SKD1、DIN 1.2080、Cr12 steel

Email Details -

Cr12W Cold Work Die Steel

Cr12W is the national standard GB executive standard steel grade. It is a high carbon C, chromium Cr cold work die steel. This steel contains about 0.70% of tungsten W, which makes it have high hardness, strength, wear resistance, toughness, and high hardenability. The hardenability and other process properties are 3 to 4 times higher than those of ordinary low alloy tool steel and the quenching volume deformation is small.Our company provides Cr12W round rods and Cr12W steel plates

Email Details -

Cr12Mo1V1 Cold Work Die Steel

Cr12Mo1V1 ledeburite steel is a widely used high-carbon, high-chromium cold work die steel in the world. It is a ledeburite steel with high hardenability, hardenability and high wear resistance. It has good high-temperature oxidation resistance and is resistant to corrosion after quenching and polishing. It has good corrosion resistance and small heat treatment deformation.

Email Details