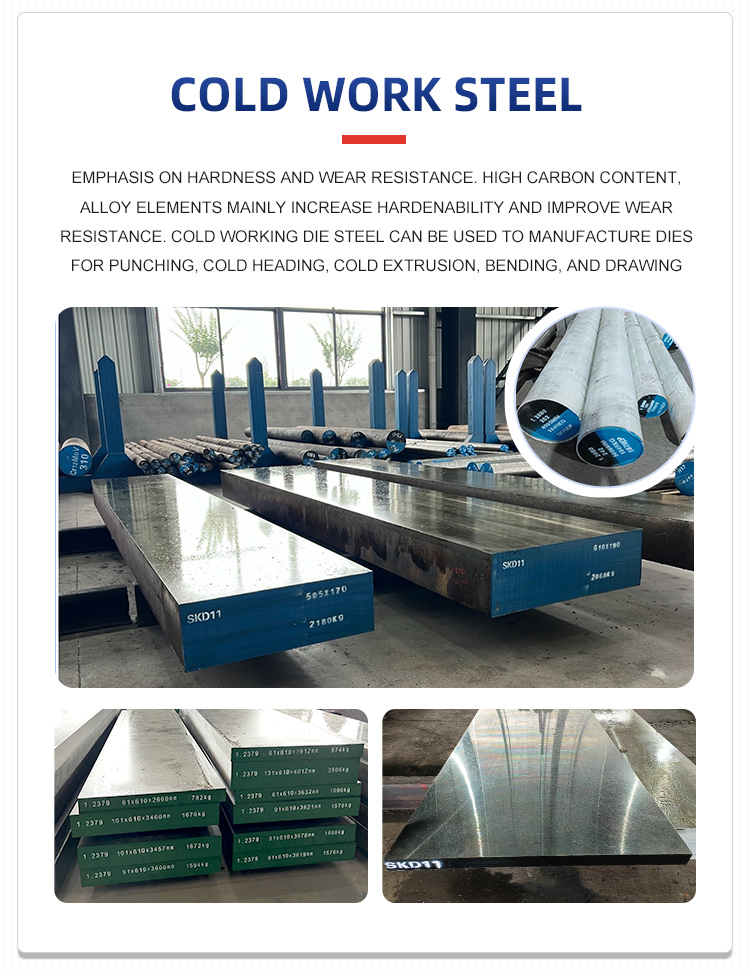

Cr12Mo1V1 Cold Work Die Steel

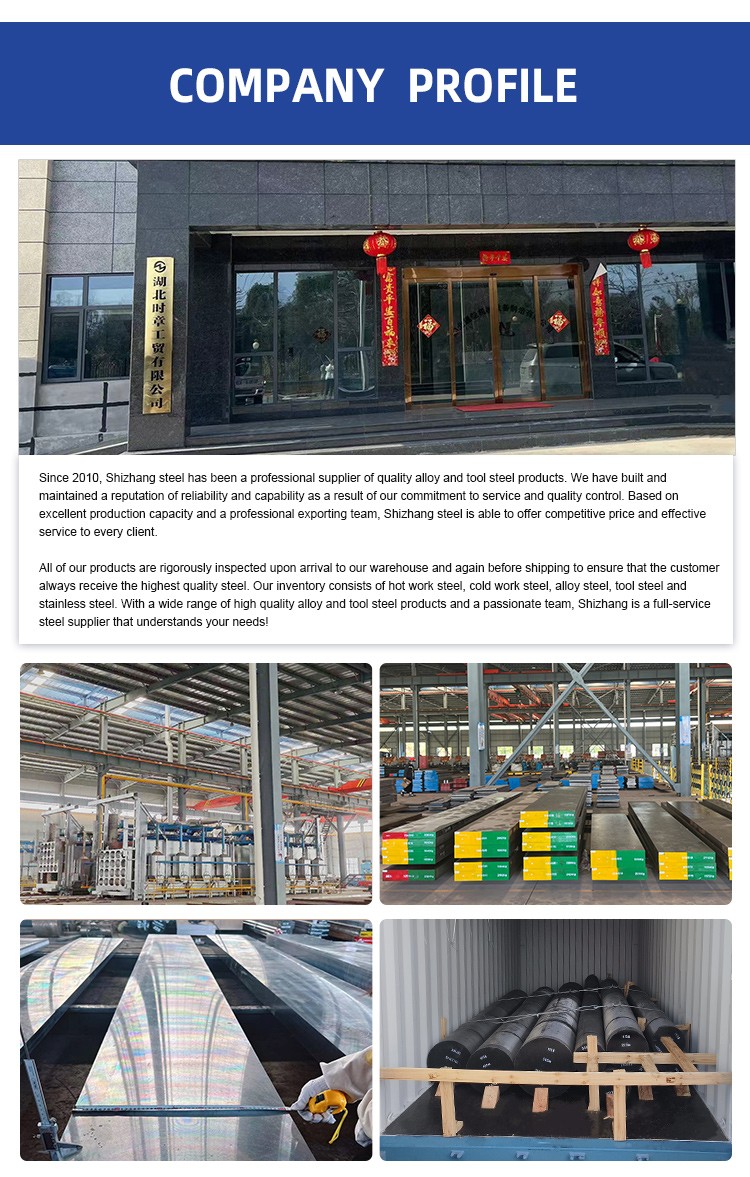

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

Cr12Mo1V1 ledeburite steel is a widely used high-carbon, high-chromium cold work die steel in the world. It is a ledeburite steel with high hardenability, hardenability and high wear resistance. It has good high-temperature oxidation resistance and is resistant to corrosion after quenching and polishing. It has good corrosion resistance and small heat treatment deformation.

Product Name: COLD WORK DIE STEEL---Cr12Mo1V1

Similar steel grades:

U.S.A | T30402(UNS) |

German | DINEN:X155CrVMo121 |

Japan | SKD11 |

Austria | - |

Sweden | - |

China | Cr12Mo1V1 |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | Mo | V | Co |

GB/T1299-2014 | 1.4-1.6 | ≤0.6 | ≤0.6 | ≤0.03 | ≤0.03 | 11--13 | 0.7-1.2 | 0.5--1.1 | ≤1 |

Principal Feature:

Cr12Mo1V1 ledeburite steel is a widely used high-carbon, high-chromium cold work die steel in the world. It is a ledeburite steel with high hardenability, hardenability and high wear resistance. It has good high-temperature oxidation resistance and is resistant to corrosion after quenching and polishing. It has good corrosion resistance and small heat treatment deformation.

Typical Application:

Cr12Mo1V1 Steel is suitable for manufacturing various high-precision, long-life cold work molds, cutting tools and measuring tools, such as complex-shaped punching dies, cold extrusion dies, rolling wheels, thread rolling wheels, cold shearing knives and precision measuring tools, etc.

Heat Treatment:

Quenching, preheating at 820±15℃, heating at 1000±6℃ (salt bath) or 1010±6℃ (furnace controlled atmosphere), holding for 10~20min, air cooling, tempering at 200±6℃.

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |