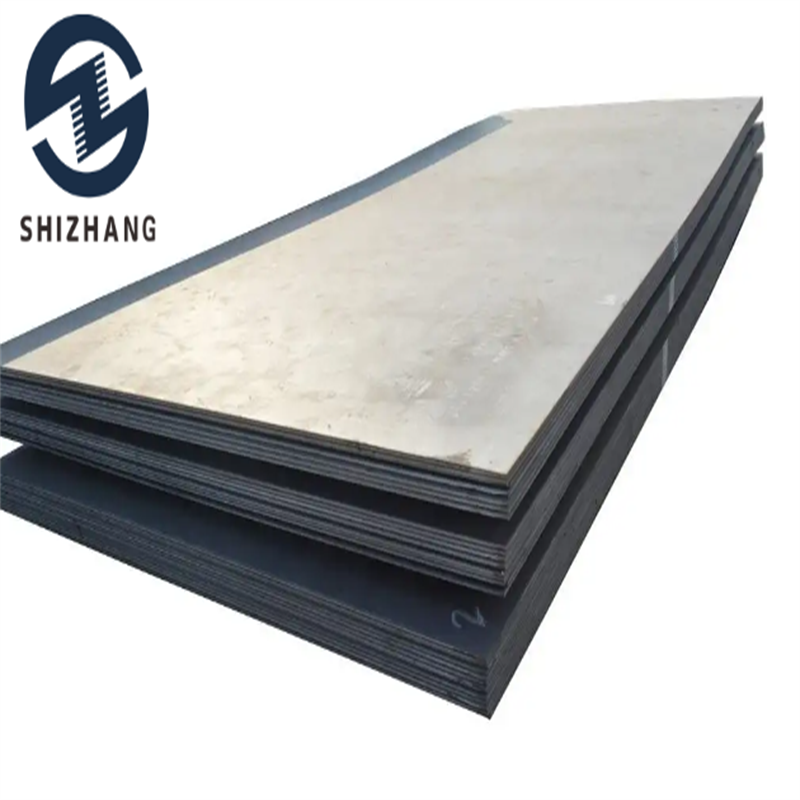

Alloy Steel

-

SCM440 Alloy Structural Steel

Medium carbon chromium-molybdenum alloy steel SCM440, an alloy steel containing chromium and molybdenum. It has the advantages of stable composition, low harmful elements, high steel purity, small decarburization layer, and few surface defects. Easy to spheroidize and has low cold cracking rate. Alloy steel SCM440 is usually hardened and tempered. The ultimate tensile strength is 850-1000Mpa. This material strikes a very good balance between strength, toughness and wear resistance. The alloy's chromium content provides good hardness penetration, while the molybdenum element imparts average hardness and high strength.

Email Details

Alloy steel SCM440 responds well to heat treatment and is easy to process under heat treatment conditions. This material offers many desirable properties such as good strength and wear resistance, excellent toughness, good ductility and resistance to high temperature stress.Our company can provide SCM440 hot-rolled or forged materials, etc. -

Hot

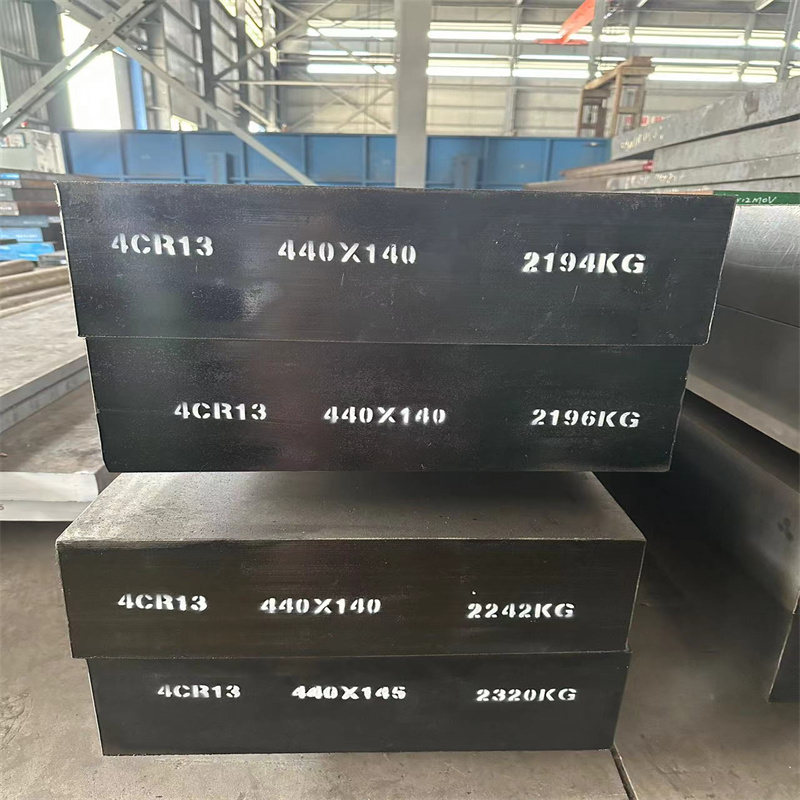

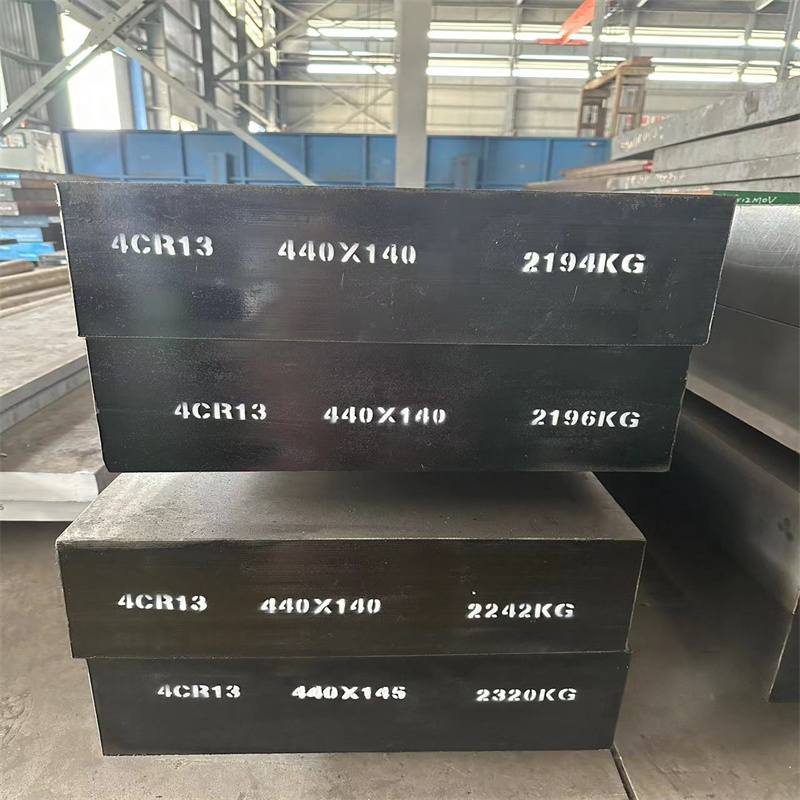

Alloy Steel 4Cr13

4Cr13 martensitic alloy steel Mainly used in the production of surgical instruments, bearings, valves, springs and high-strength molds, etc.The corresponding foreign brand of 4Cr13 steel is DIN 1.2083、ASTM 420、SUS 420J2

Email Details -

4Cr13 Alloy Steel

4Cr13 steel is a high-quality martensitic stainless steel. This steel has good machining performance. After heat treatment (quenching and tempering), it has excellent corrosion resistance, polishing performance, high strength and wear resistance, and is suitable for manufacturing to withstand high loads and high Plastic molds, bearings, electrical equipment, instruments, instruments, turbine blades, springs, cutting tools, nozzles, valve seats, valve bearings, medical equipment, etc. that are wear-resistant and exposed to corrosive media.Our company can provide 4Cr13 stainless steel round bars and plates

Email Details -

DIN 1.2358 Alloy Steel

1.2358 is a forged alloy steel. Can replace 7CrSiMnMoV. It has good toughness and wear resistance, and can be widely used in trimming die and turning die working insert. Using surface quenching process, the hardness of surface quenching HRC56 ~ 60

Email Details -

1.2746 Tool Steel

1.2746 (45NiCrMoV16-6) steel is an alloyed cold work tool steel. It is a widely used material in various industrial applications. This steel type has high hardness and can withstand challenging conditions such as wear, impact, and high temperatures. Due to its excellent mechanical and thermal stability at elevated temperatures (500-600 °C), 1.2746 (45NiCrMoV16-6) steel is particularly preferred for components operating at high temperatures.

Email Details -

Cr2 Alloy Tool Steel

Cr2 steel adds a certain amount of Cr compared to carbon tool steel, and Cr2 steel is equivalent to ball bearing steel GCr15 in composition. Therefore. Its hardenability, hardness and wear resistance are higher than carbon tool steel, wear resistance and contact fatigue strength are also high.

Email Details -

Cr06 Alloy Steel

Cr06 steel for measuring and cutting tools is a low alloy tool steel containing a small amount of chromium. The hardness and wear resistance after quenching are high, the hardenability is not good, and the hardness is brittle.

Email Details -

AISI S7 Tool Steel

AISI S7 steel is a kind of advanced tool steel. AISI S7 tool steel has excellent wear resistance, deformation resistance and corrosion resistance. AISI S7 steel also has the characteristics of high hardness and high strength, and can still maintain excellent performance in high temperature environments.our company are tool steel suppliers.

Email Details -

Alloy Steel 2Cr13

2Cr13 alloy steel is 420 "knife grade" martensitic steel, similar to Brinell high chromium steel, the earliest stainless steel. 2Cr13 has certain wear resistance and corrosion resistance, high hardness, and its price is the lowest among stainless steel balls. It is suitable for working environments with common requirements for stainless steel. 2Cr13 alloy steel is suitable for all types of precision machinery, bearings, electrical appliances, equipment, instruments, meters, transportation vehicles, household appliances, etc. It is mostly used to manufacture parts that are resistant to atmospheric, steam, water and oxidizing acid corrosion.The corresponding foreign brand of 2Cr13 is ASTM 420、DIN 1.4021、SUS 420J1、GB 20Cr13

Email Details