Alloy Steel 2Cr13

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

2Cr13 alloy steel is 420 "knife grade" martensitic steel, similar to Brinell high chromium steel, the earliest stainless steel. 2Cr13 has certain wear resistance and corrosion resistance, high hardness, and its price is the lowest among stainless steel balls. It is suitable for working environments with common requirements for stainless steel. 2Cr13 alloy steel is suitable for all types of precision machinery, bearings, electrical appliances, equipment, instruments, meters, transportation vehicles, household appliances, etc. It is mostly used to manufacture parts that are resistant to atmospheric, steam, water and oxidizing acid corrosion.The corresponding foreign brand of 2Cr13 is ASTM 420、DIN 1.4021、SUS 420J1、GB 20Cr13

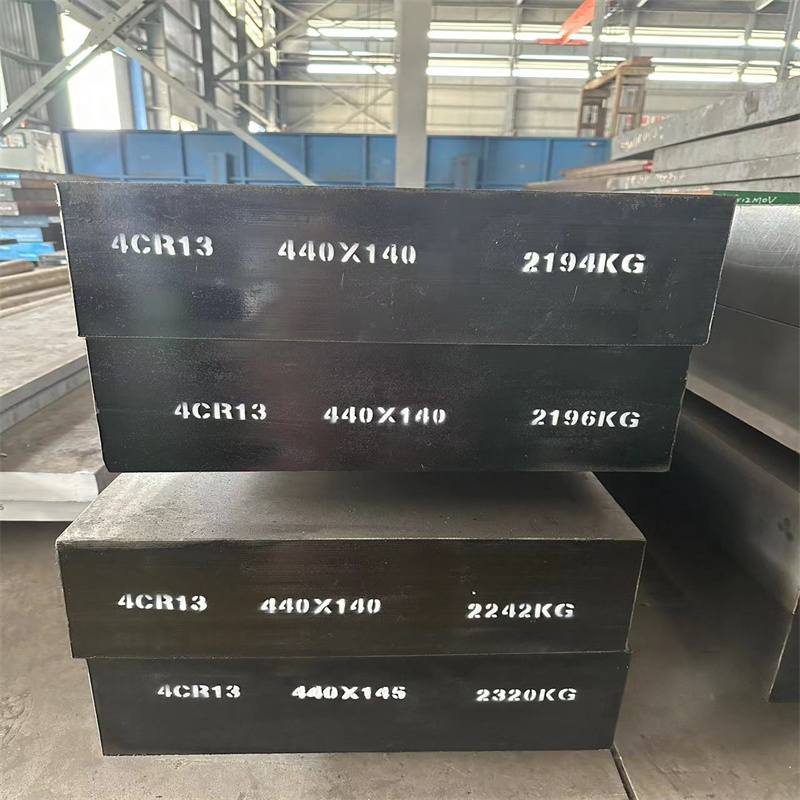

Product Name:ALLOY STEEL---2Cr13

Similar steel grades:

U.S.A | ASTM 420 |

German | X20Cr13/DIN 1.4021 |

Japan | SUS 420J1 |

Austria | - |

Sweden | - |

China | 2Cr13/20Cr13(new) |

Chemical composition:

Standard | C | Si | Mn | Cr | Ni | P | S |

GB/T1220-2007 | 0.16-0.25 | ≤1.0 | ≤1.0 | 12.00-14.00 | ≤0.60 | ≤0.035 | ≤0.03 |

Principal Feature:

2Cr13 alloy steel should be classified as stainless steel. A more precise classification should be classified as martensitic stainless iron. It is mainly used for mechanical processing and has better cost performance than normal stainless steel. Therefore, it does not require corrosion resistance. In higher cases, it has been more widely used. After quenching, 2Cr13 can obtain better mechanical properties, has better processability, and has a martensite structure.

Typical Application:

2Cr13 alloy steel mainly used in:

1. Mechanical structural parts, engine exhaust pipes, boiler combustion chambers, and burners.

2. Building exterior decoration materials, automobile parts, hot and cold water supply equipment.

3. It is used in outdoor open-air machines in the chemical, coal, and petroleum industries that require high resistance to grain boundary corrosion, heat-resistant building material parts, and parts that are difficult to heat treat.

Heat Treatment:

Annealing : slow cooling at 800~900℃ or rapid cooling at about 750℃;

Quenching : 920~980℃ oil cooling;

Tempering : rapid cooling at 600~750℃.

Metallographic structure : The structure is characterized by martensitic structure.

Size available:

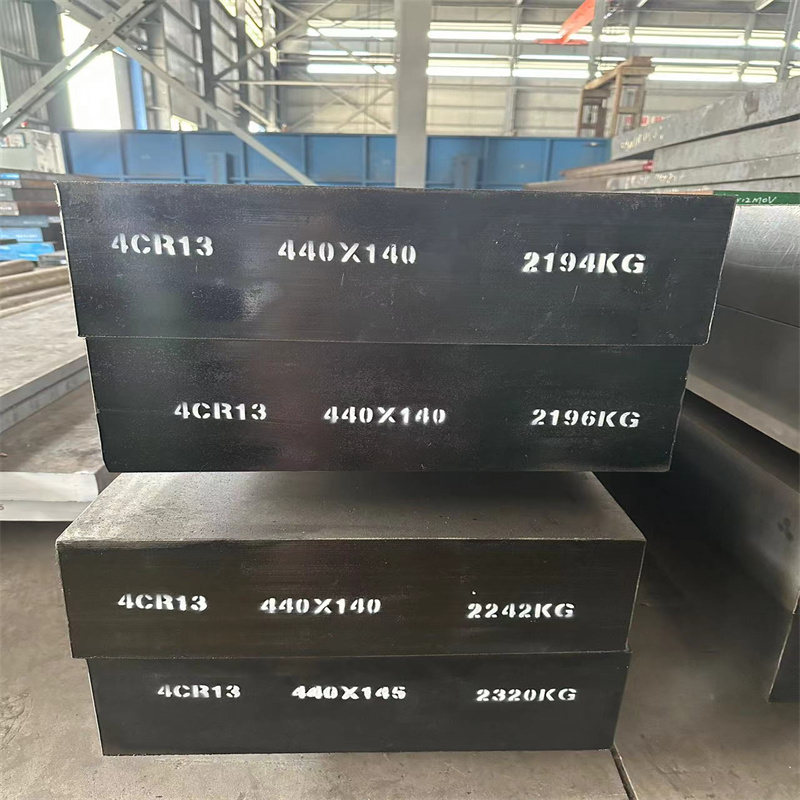

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |