Alloy Steel 4Cr13

- Shizhang Steel

- China

- 15-45

- 500 Tons/Month

4Cr13 martensitic alloy steel Mainly used in the production of surgical instruments, bearings, valves, springs and high-strength molds, etc.The corresponding foreign brand of 4Cr13 steel is DIN 1.2083、ASTM 420、SUS 420J2

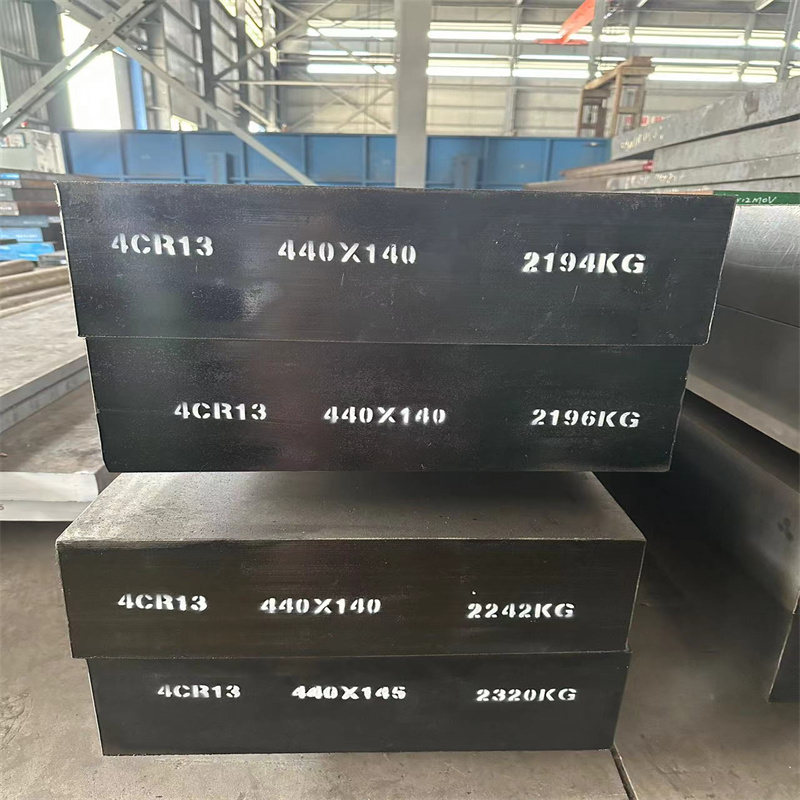

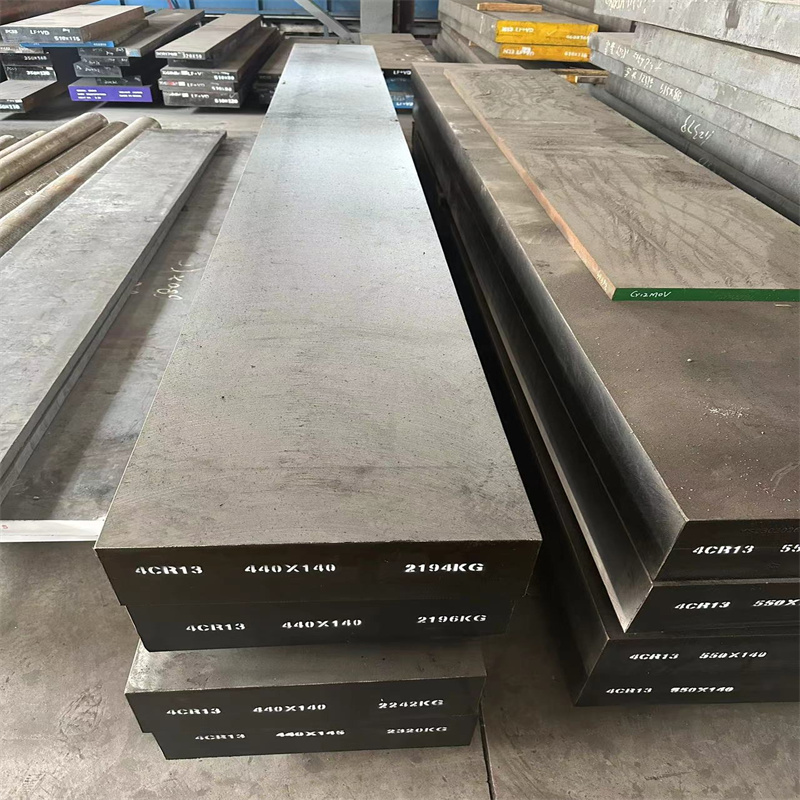

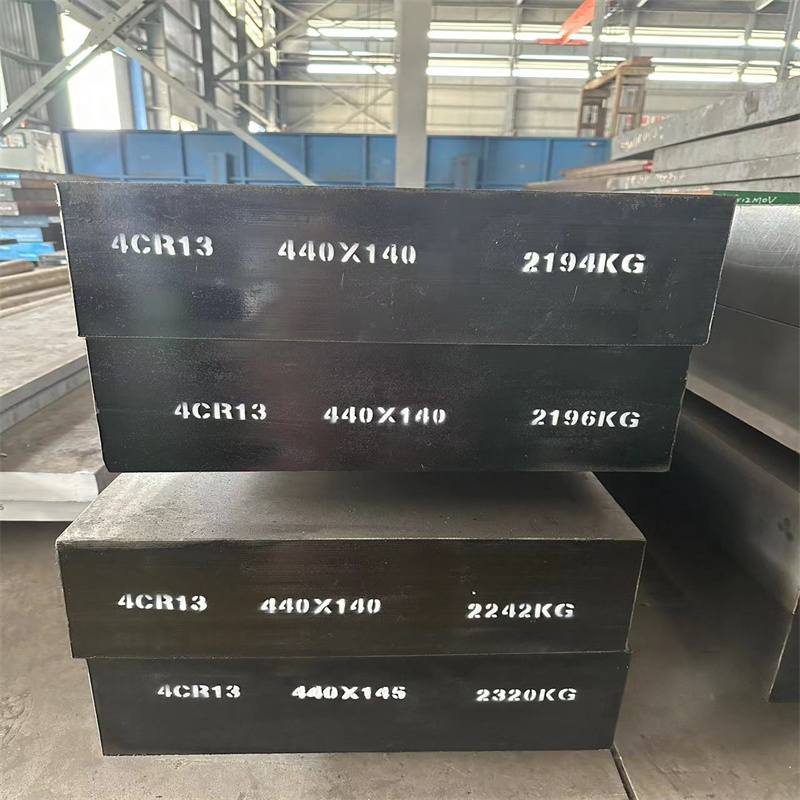

Product Name: ALLOY STEEL---4Cr13

Similar steel grades:

U.S.A | ASTM 420 |

German | DIN 1.2083 |

Japan | SUS 420J2 |

Austria | M310 |

Sweden | S136 |

China | 4Cr13 |

Chemical composition:

Standard | C | Si | Mn | Cr | Ni | P | S | V |

FTBI-2000 | 0.36-0.45 | ≤0.60 | ≤0.80 | 12.00-14.00 | ≤0.60 | ≤0.03 | ≤0.03 | ≤0.03 |

Principal Feature:

4Cr13 martensitic alloy steel ,Corrosive Resistance And Super Mirror-like. Stainless martensitic with a high hardenability, good polishing properties, excellent resistance to corrosion and hot oxidation. Annealing hardness HB 235max. Prehardened to HRC 30-36 mirror-like to easy machining, deformation effected by hardened could off.

Typical Application:

4Cr13 martensitic alloy steel is mainly used to make surgical instruments, bearings, valves, springs, etc.

Heat Treatment:

Forge: at 900℃-1100℃ Cool slowly and anneal immediatedly

Anneal: at 880℃ Cool slowly in furnace

Stress Relieve: at to 600℃-650℃ Cool in still air

Harden: Preheat at 600℃-850℃ raise to 1020℃-1100℃ Cool in air, iol or into salt bath held at 200℃-300℃ and then air cool

Size available:

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |