Cold Work Die Steel 1.2436(X210CrW12)

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

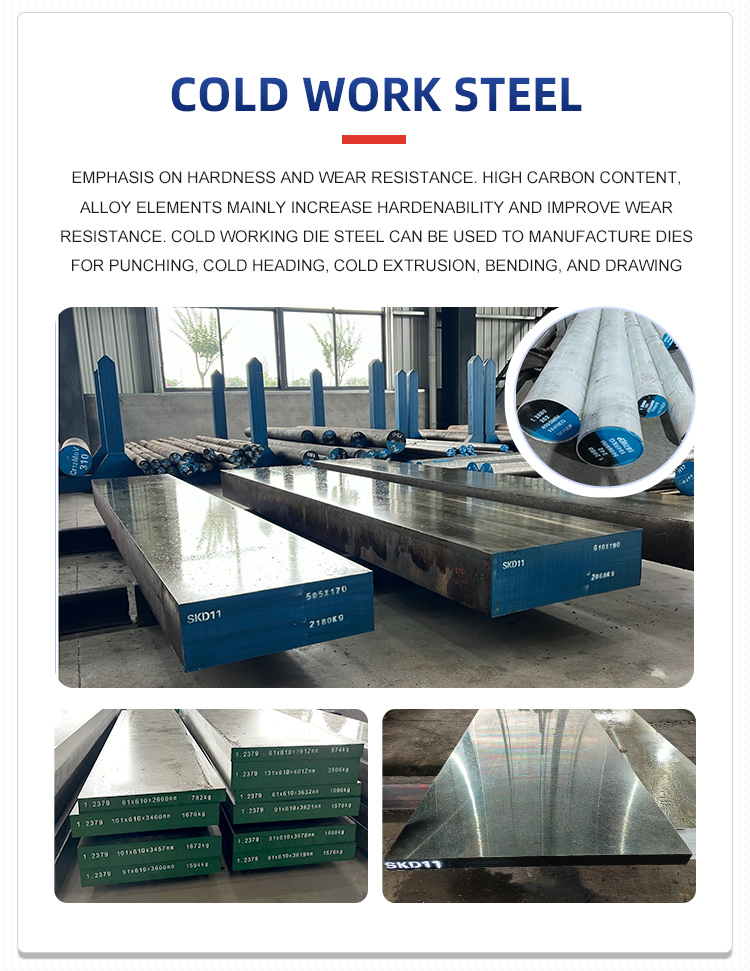

DIN 1.2436 cold work die steel is German DIN standard extra high toughness chromium steel. Has extremely high wear resistance and edge retention capabilities. It is a widely used cold work die steel with high strength, good hardenability and good wear resistance, but poor impact toughness.Our company provides DIN 1.2436 steel plates and DIN 1.2436 Cold Work Mold Steel Round Bar

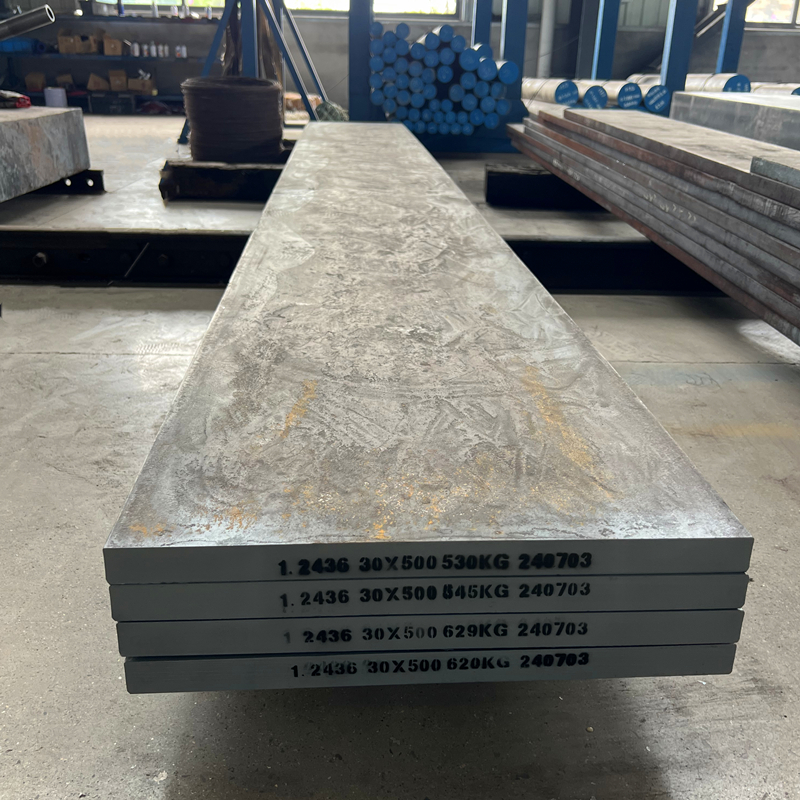

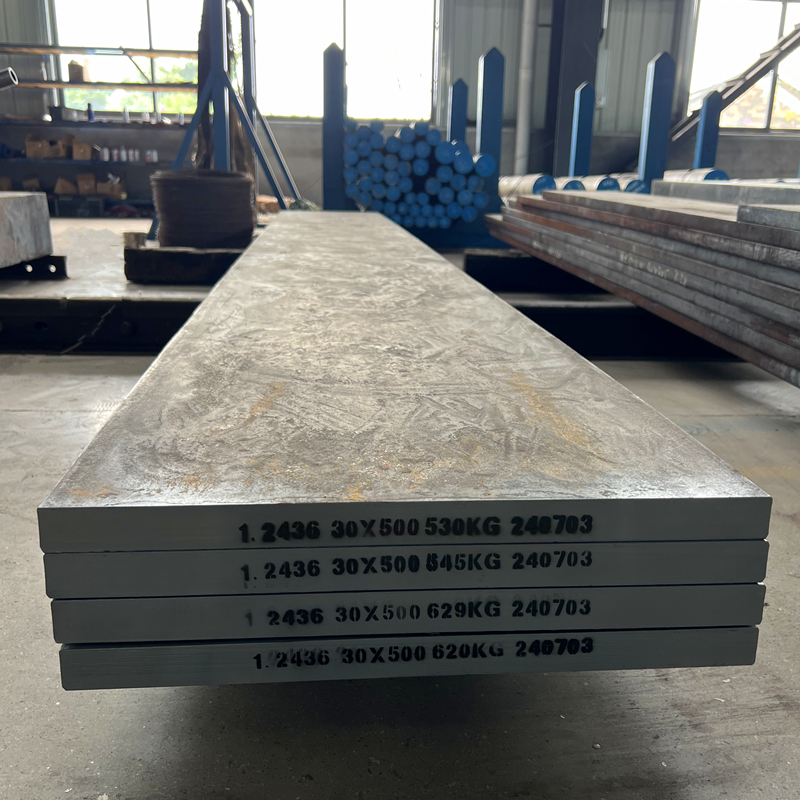

Product Name: COLD WORK DIE STEEL---1.2436

Similar steel grades:

U.S.A | D6 |

German | 1.2436 |

Japan | JIS SKD2 |

Austria | - |

Sweden | - |

China | GB Cr12W |

Chemical composition:

Standard | C | Si | Mn | P | S | Cr |

DIN 17350 | 2.00-2.30 | ≤0.40 | ≤0.40 | ≤0.030 | ≤0.030 | 11.50-13.00 |

Principal Feature:

1.High hardness: Through heat treatment, the hardness of 1.2436 steel can reach HRC60 or more, with extremely high wear resistance and durability.

2. High temperature strength and toughness: At high temperatures, the strength and toughness of 1.2436 steel can still maintain a high level, which is suitable for manufacturing molds and tools that need to withstand high temperatures and heavy loads.

3. Excellent cutting performance: Due to its high hardness and high wear resistance, 1.2436 steel has good cutting performance and can be used to manufacture various cutting tools and knife tools.

4. Good hardenability and quenching sensitivity: DIN 1.2436 has good hardenability and quenching sensitivity, and the required mechanical properties can be obtained through quenching and tempering treatment.

Typical Application:

Din 1.2436(X210CrW12) is also equivalent to AISI D6 tool steel, it mainly used for cold punching dies and punches, cold cutting scissors, drill sleeves, gauges, wire drawing dies, stamping dies, wire rolling dies, drawing dies and thread rolling dies that bear small impact loads and require high wear resistance.

Din 1.2436 (X210CrW12) Cold work steel, because of its high hardness, high wear resistance and excellent heat resistance, is mainly used in the manufacture of various molds, cutting tools and wear-resistant parts.

1. 1.2436 is suitable for the manufacture of various types of cold work molds, die casting molds and injection molds. Due to its high hardness and wear resistance, 1.2436 is also widely used in the plastic processing industry, such as manufacturing injection molds, extrusion molds and blow molds .

2. 1.2436 is also used to manufacture cutting tools , such as milling cutter, drill, turning tool and so on. These tools keep sharp during cutting and extend the life of the tool .

3. 1.2436 is also used to manufacture wear-resistant parts , such as rolls, conveyor belts, wear-resistant plates, etc. In heavy machinery manufacturing, 1.2436 can be used to manufacture parts that withstand heavy loads and high impacts, such as mining machinery, excavators, etc .

4. 1.2436 also has applications in other fields , such as the application of casting mold mainly includes cast iron mold and aluminum alloy mold. It is also used in the manufacture of cold shear scissors, blanking molds in the paper and plastics industry, and molds in the ceramic industry.

Heat Treatment:

Quenching temperature 960-980℃, oil cooling. Tempering temperature 180℃±10℃

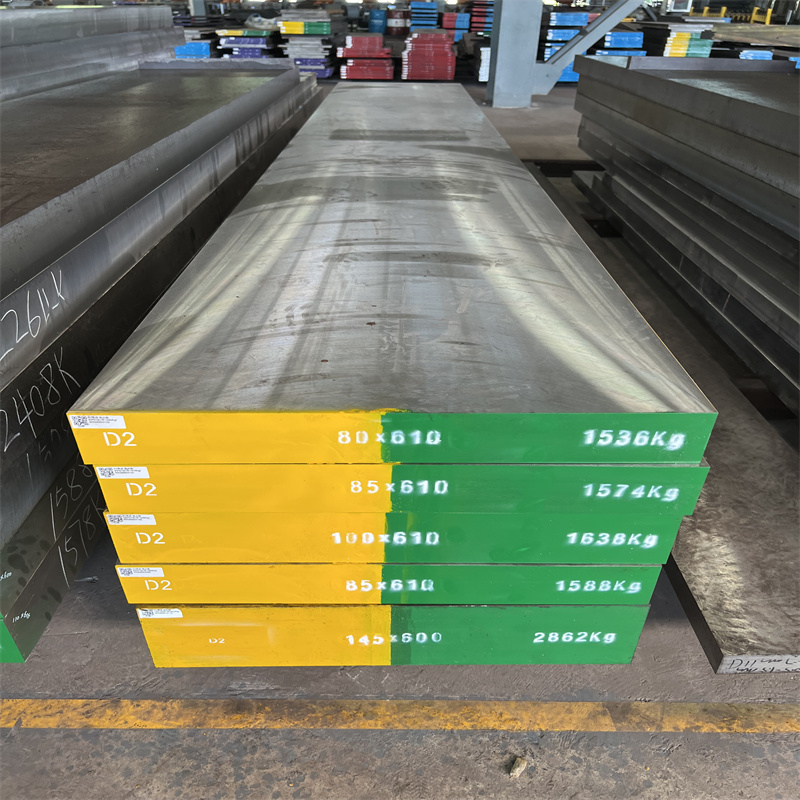

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |