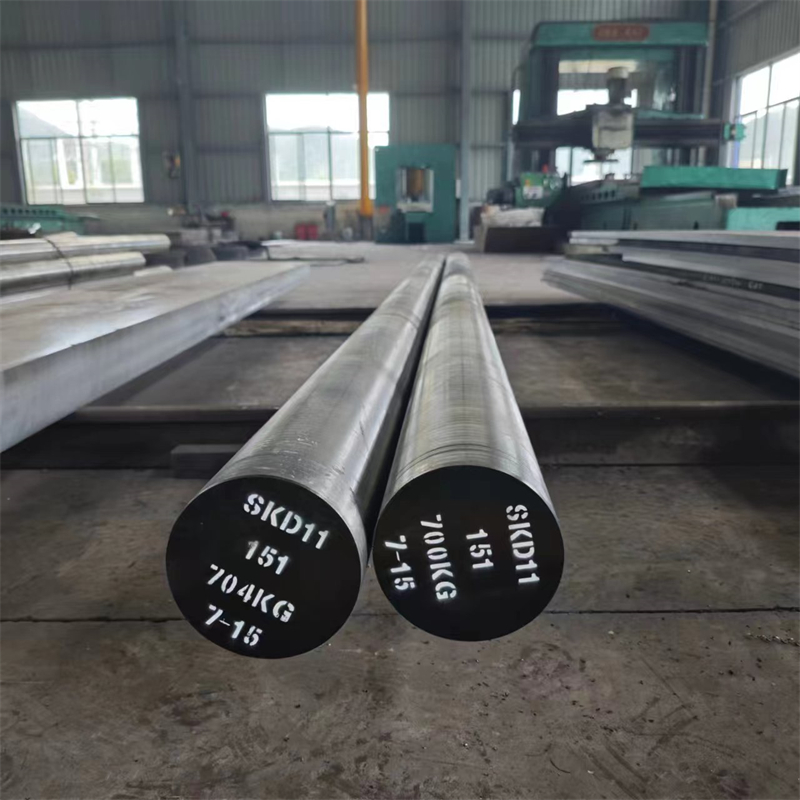

SKD11 Cold Work Die Steel

- Shizhang Steel

- China

- 15-45

- 500 Tons/Month

SKD11 is precision stamping mold steel、Ledeburitic 12% chrome steel, very high resistanceagainst abrasive and adhesive wear due to a highvolume of hard carbides in the steel matrix, goodtoughness,very gooddimensional stability, highcompressive strength, very good base material forPVD/CVD coating as well as nitriding due to itssecondary hardening properties.The corresponding grade of SKD11 is Equivalant to DIN 1.2379 、JIS SKD11 tool steel or GB Cr12Mo1V1

Product Name: COLD WORK TOOL STEEL---SKD11

Similar steel grades:

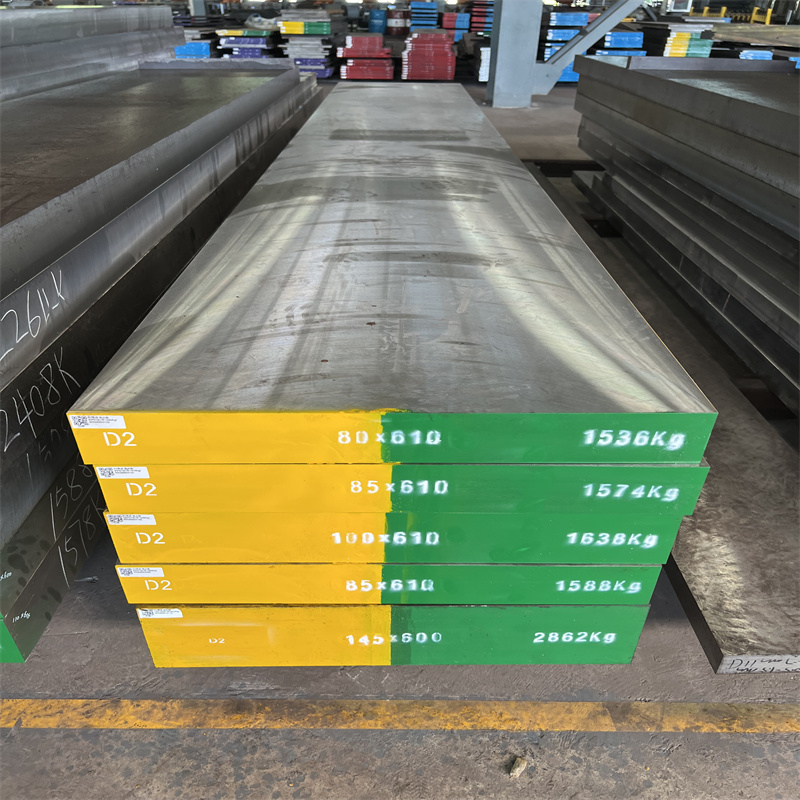

U.S.A | D2 |

German | 1.2379 |

Japan | SKD11 |

Sweden | -- |

China | Cr12Mo1V1 |

Chemical Composition(%) :

C | Si | Mn | Cr | Mo | P | S |

1.50-1.60 | 0.10-0.40 | 0.15-0.45 | 11.0-12.0 | 0.60-0.80 | 0.03max | 0.03max |

Principal Feature:

SKD11 cold work tool steel is versatile high-carbon, high-chromium, air-hardening tool steel that is characterized by a relatively high attainable hardness and numerous, large, chromium-rich alloy carbides in the microstructure.

Typical Application:

SKD11 cold work tool steel can be used for Cutting, punching, stamping tools, shear blades, thread rolling dies, cold extrusion dies, drawing and bending tools, flanging and straightening rolls, fine cutting tools deep drawing tools, plastic moulds for abrasive polymers

Heat Treatment:

Forge: at 900℃-1100℃ Cool slowly and anneal immediately

Annealing: at 830℃-860℃ Cool slowly in furnace

Stress Relieving: at to 650℃-700℃ Cool in furnace or still air

Hardening: Preheat at 650℃-850℃ raise to 1000℃-1050℃ Cool in air, oil or into hot bath held at 500℃-550℃ and then air cool

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |

We can provide professional steel as per your detail requirement!