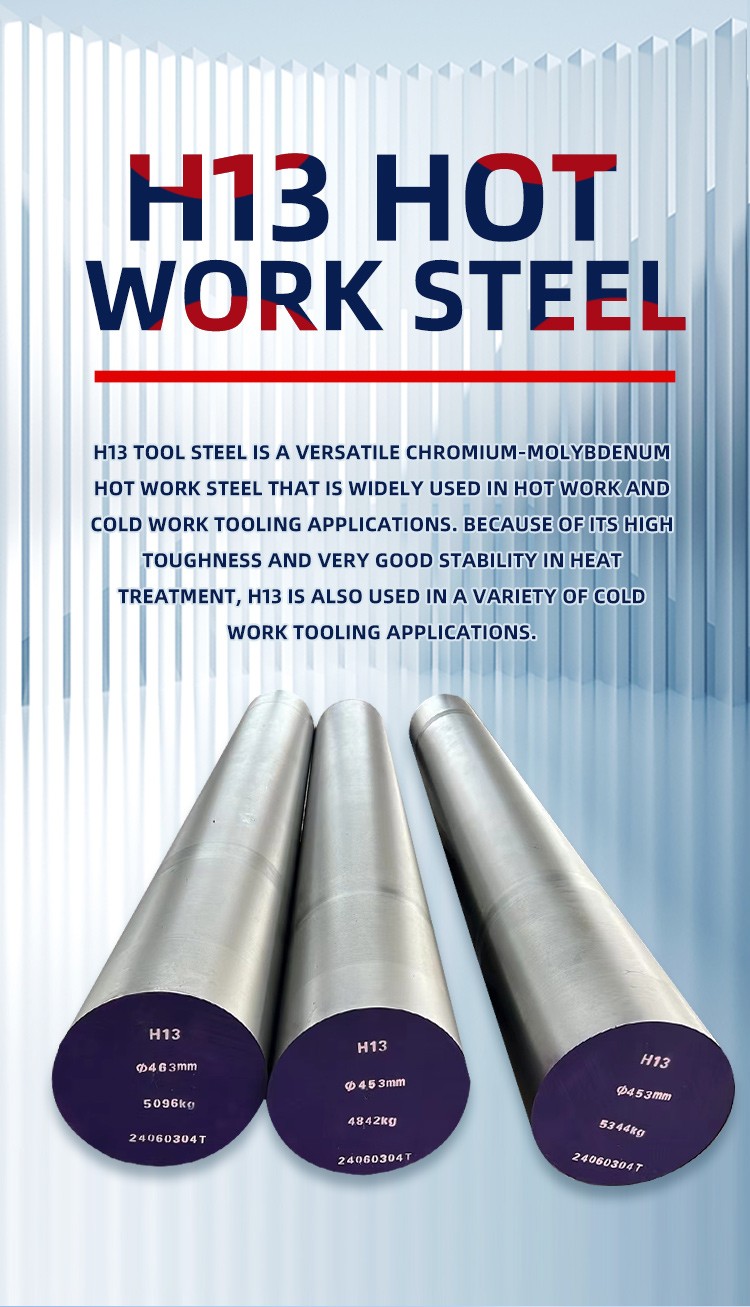

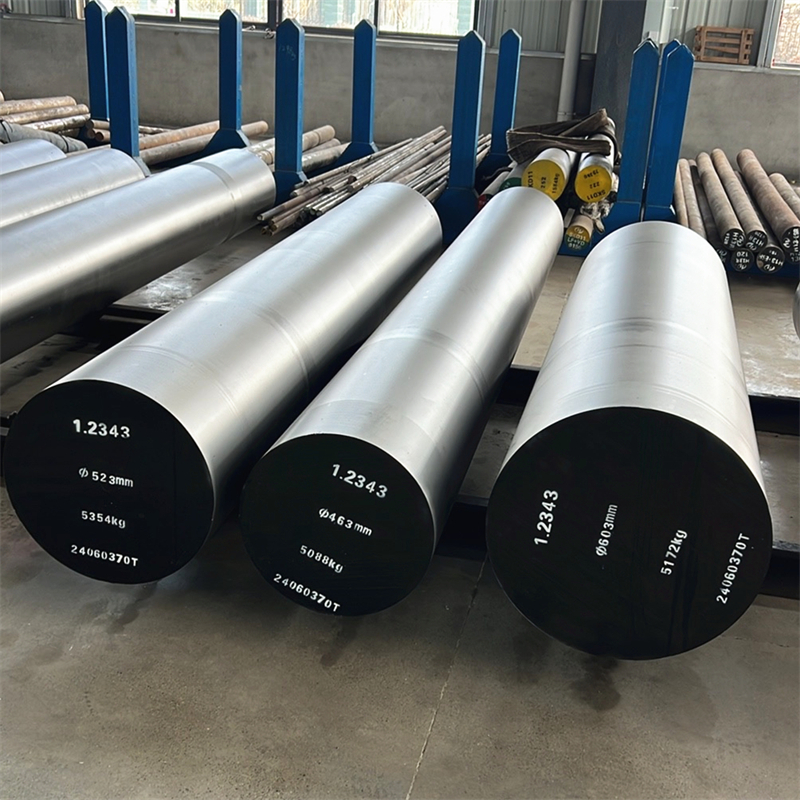

H13 Hot Work Die Steel

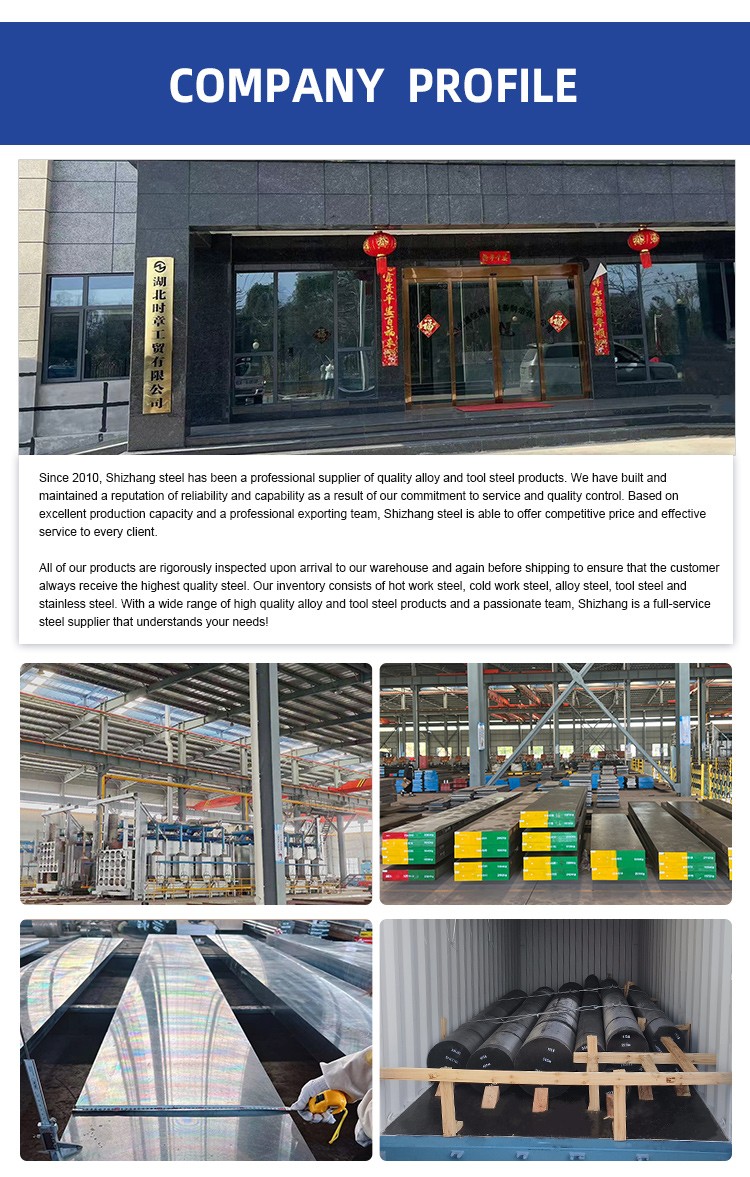

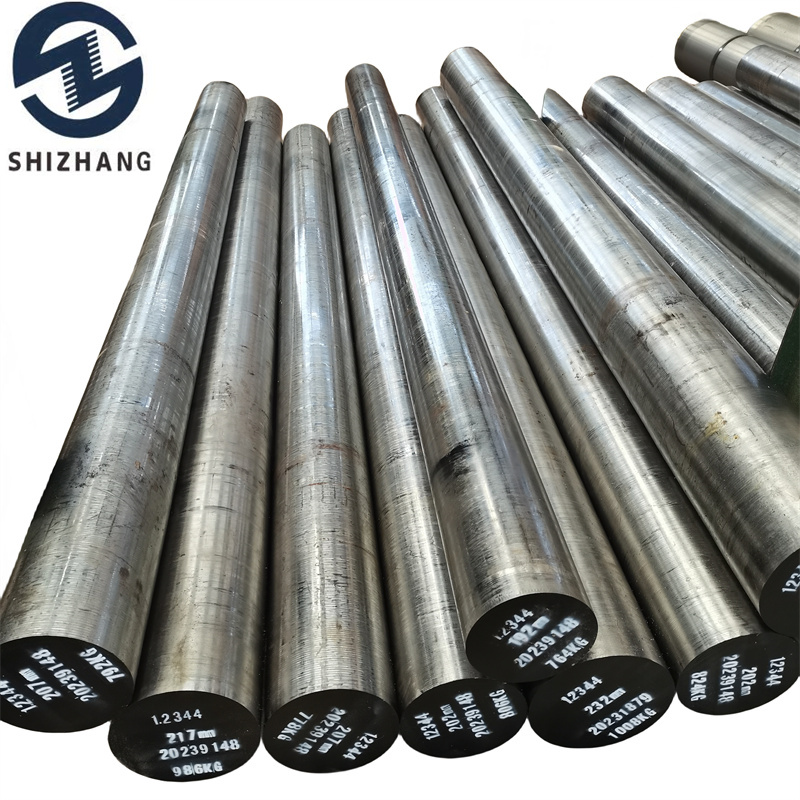

- Shizhang Steel

- China

- 7-30days

- 500 Tons/Month

AISI H13 tool steel is characterized by its high hardness, wear resistance, toughness, and corrosion resistance. AISI H13 steel can withstand high temperature and high pressure loads. AISI H13 steel can reduce the tooling wear and improve production efficiency.

Product Name: HOT WORK DIE STEEL---H13

Similar Steel Grades:

AISI | H13 |

DIN | 1.2344 |

JIS | JIS SKD61 |

ASSAB | 8407 |

GB/T1299-2000 | 4Cr5MoSiV1 |

ISO | X40CrMoV5-1 |

Chemistry (in %)

C | Si | Mn | Cr | Mo | V | P | S |

0.32-0.45 | 0.80-1.20 | 0.20-0.50 | 4.75-5.50 | 1.10-1.75 | 0.80-1.20 | Max. 0.03 | Max.0.03 |

Principal Feature:

AISI H13 tool steel air hardening, with good toughness, resistance. AISI H13 steel resists softening to 550℃ and has good resistance to heat checking. Will nitride with a case hardness over 1000 V.P.N. Generally supplied annealed to HB 230.

Typical Application:

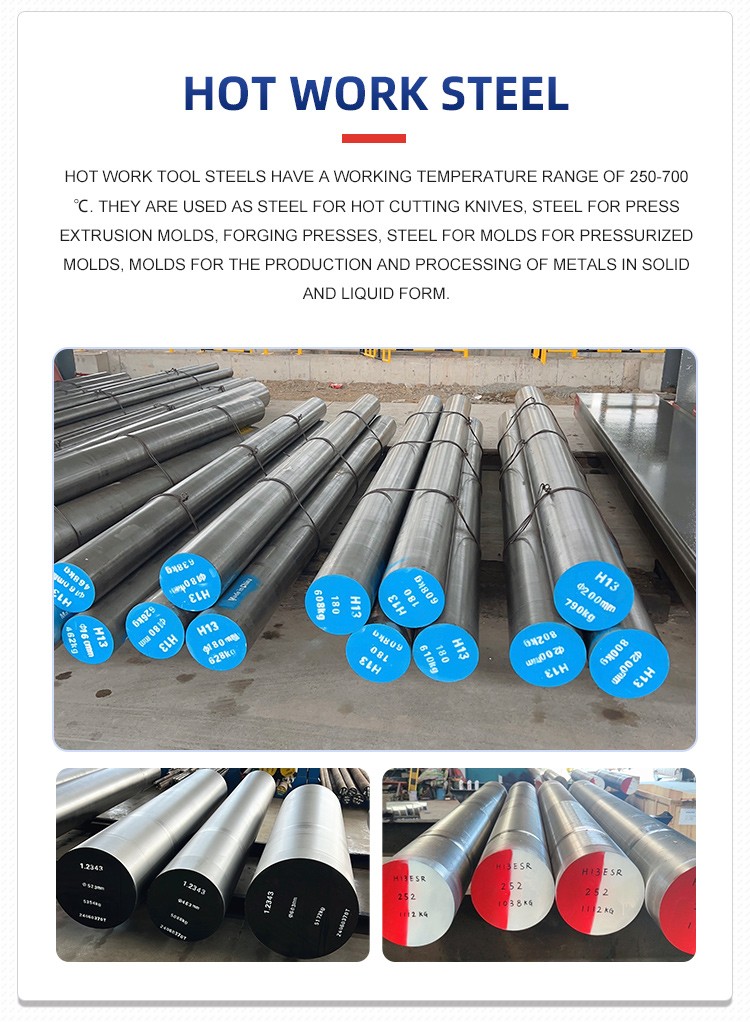

AISI H13 steel hot punches and dies for blanking, bending, swagging and forging, hot extrusion dies for aluminum, cores, ejector pins, inserts and nozzles for aluminum, tin and lead die casting.

Heat Treatment:

Forge: at 900℃-1100℃ Cool slowly and anneal immediately

Annealing: at 850℃-870℃ Cool slowly in furnace

Stress Relieving: at to 600℃-650℃ Cool in still air

Hardening: Preheat at 650℃-850℃ raise to 1020℃-1050℃ Cool in air, oil or into salt bath held at 500℃-550℃ and then air cool

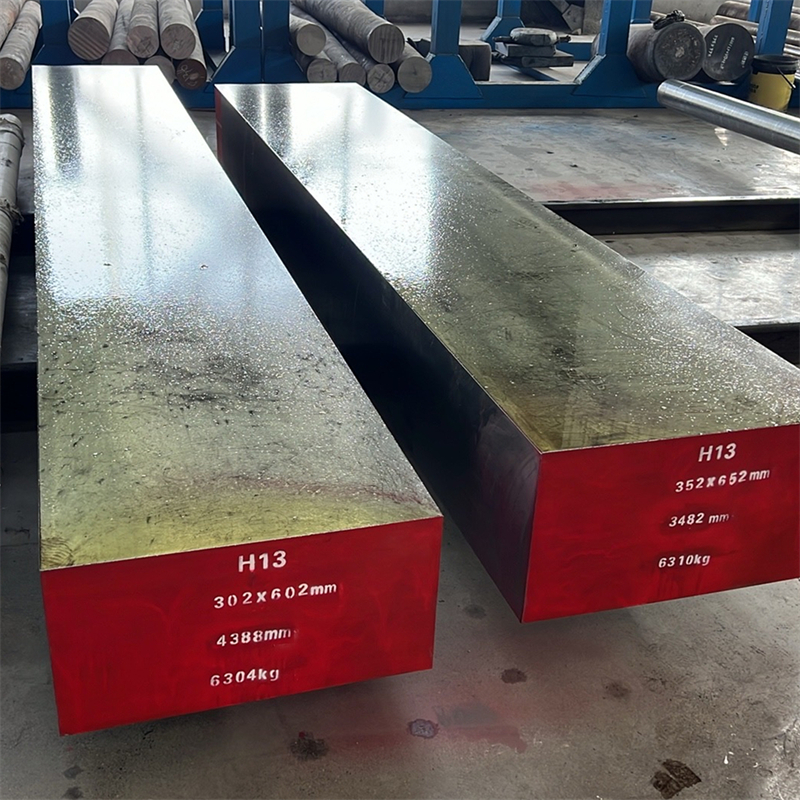

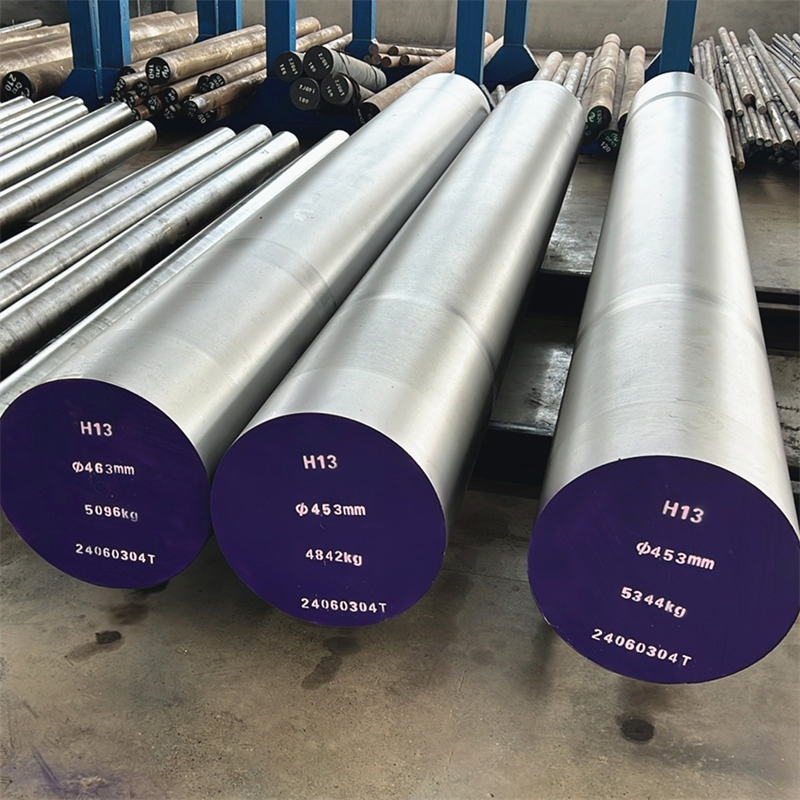

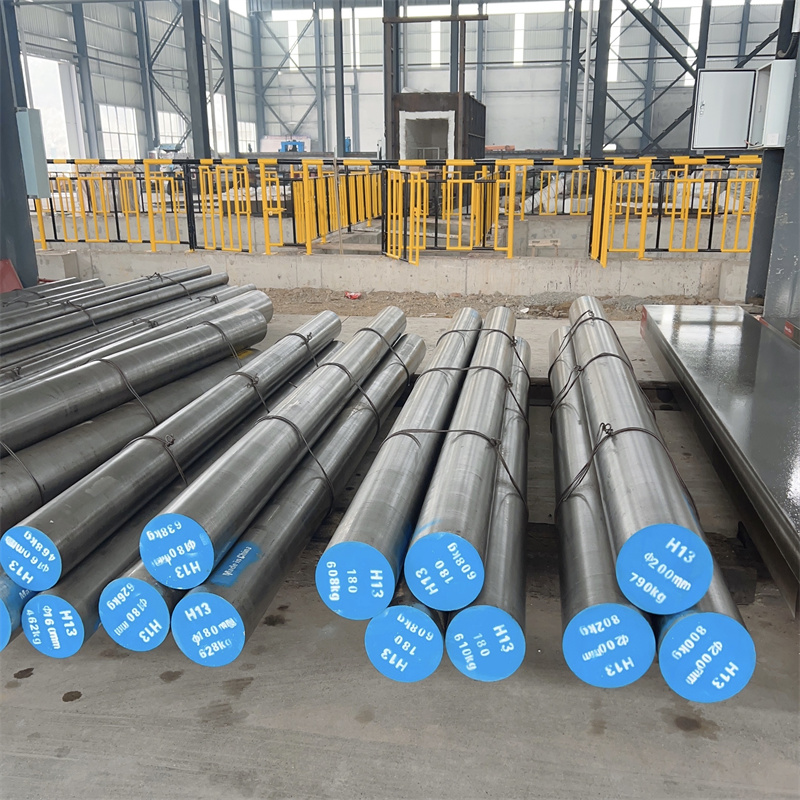

Size Available:

Bars | Turned | Dia 20-800mm |

Black | Dia 20-800mm | |

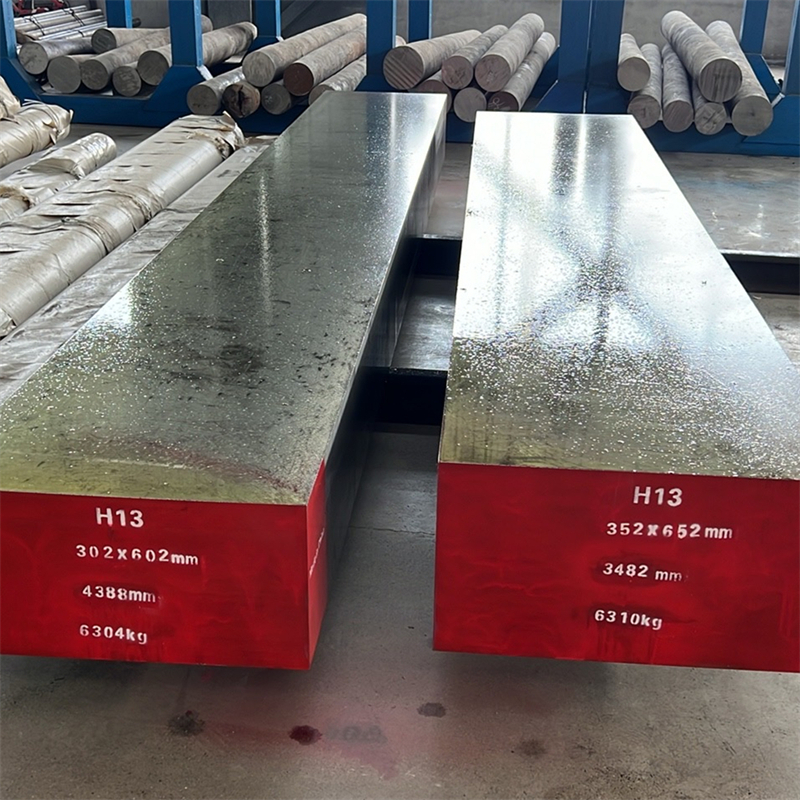

Plats | Milled | T: 50-300 W: 200-710mm |

Black | T: 8-300 W: 200-710mm |