1.2343 Hot Work Die Steel

- Shizhang Steel

- China

- 7-30days

- 500 Tons/Month

1.2343 steel is often used for highly stressed structural parts such as aircraft landing gear. lt resistssoftening at temperatures up to 537°C while retaining good ductility and toughness even atstrength levels on the order of 275 ksi. Tools for hot forging of light metal. Pressure die casting tools. Dies, mandrels, punchers, knives, moulds. This grade can be water cooled.The 1.2343 steel equivalent is AISI H11、X37CrMoV5、4Cr5MoSiV

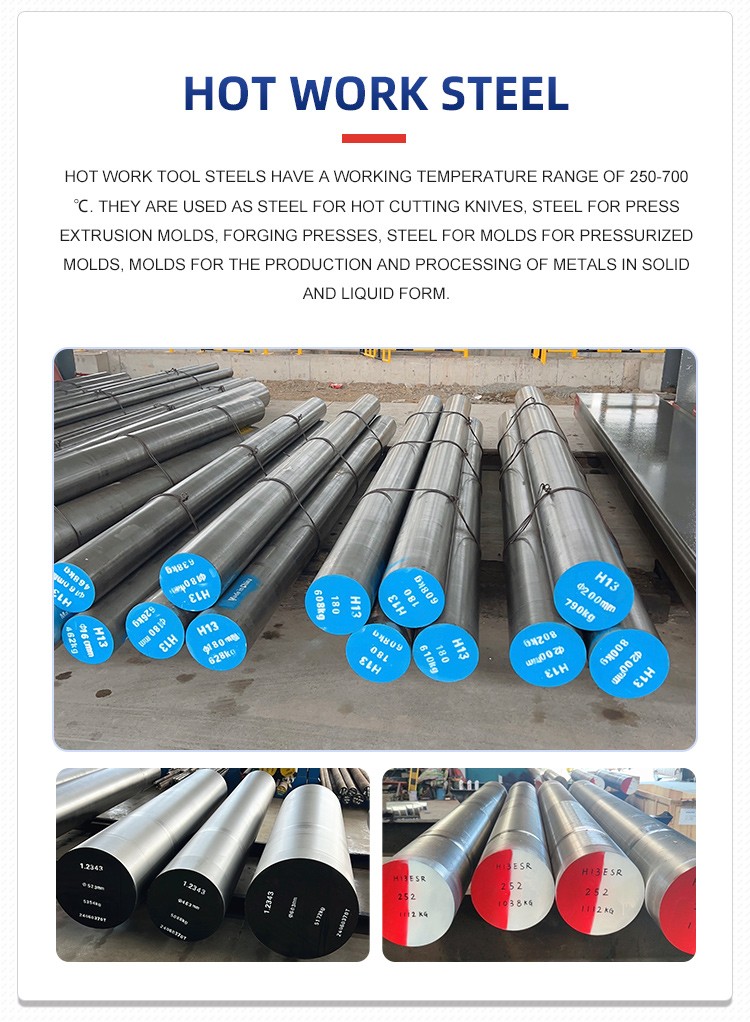

Product Name: HOT WORK TOOL STEEL---1.2343

Similar steel grades:

AISI | H11 |

W. Nr. | 1.2343 |

DIN | X37CrMoV5 |

JIS | - |

GB/T1299-2000 | 4Cr5MoSiV |

ISO | X37CrMoV5-1 |

Chemistry (in %)

C | Cr | Mo | Si | V | Mn | P | S |

0.33-0.43 | 4.75-5.5 | 1.1-1.6 | 0.8-1.2 | 0.3-0.6 | 0.2-0.5 | ≤0.03 | ≤0.03 |

Principal Feature:

1.2343 steel is a 5% chromium hot work steel that is characterized by excellent impact toughness. It contains less vanadium than the widely-used H13 hot work tool steel. 1.2343 steel is a deep-hardening, air-hardening steel that exhibits minimal size change during heat treatment. It has good resistance to thermal fatigue cracking (heat checking) and excellent resistance to gross cracking and thermal shock when water cooled in service.1.2343 steel is recommended for hot tooling applications where maximum resistance to cracking is required.

Typical Application:

Hot punches, die casting dies, forging dies, hot shear blades, hot gripper dies and extrusion tooling.

Heat Treatment:

Forge: at 1050℃-1095℃ Cool slowly and anneal then.

Annealing: at 843℃-898℃ Cool slowly in furnace

Stress Relieving: heat slowly to 566-676℃, and then cool in still air.

Hardening: Preheat to 815 ℃ and then heat to 1010℃ and hold for 15 to 40 minutes. Air cool (air quench)

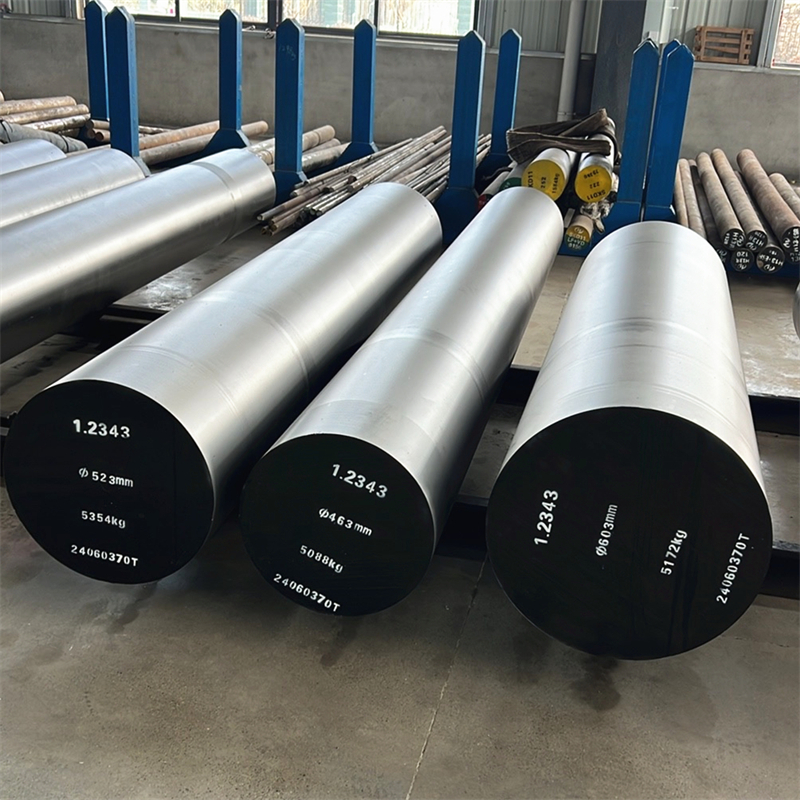

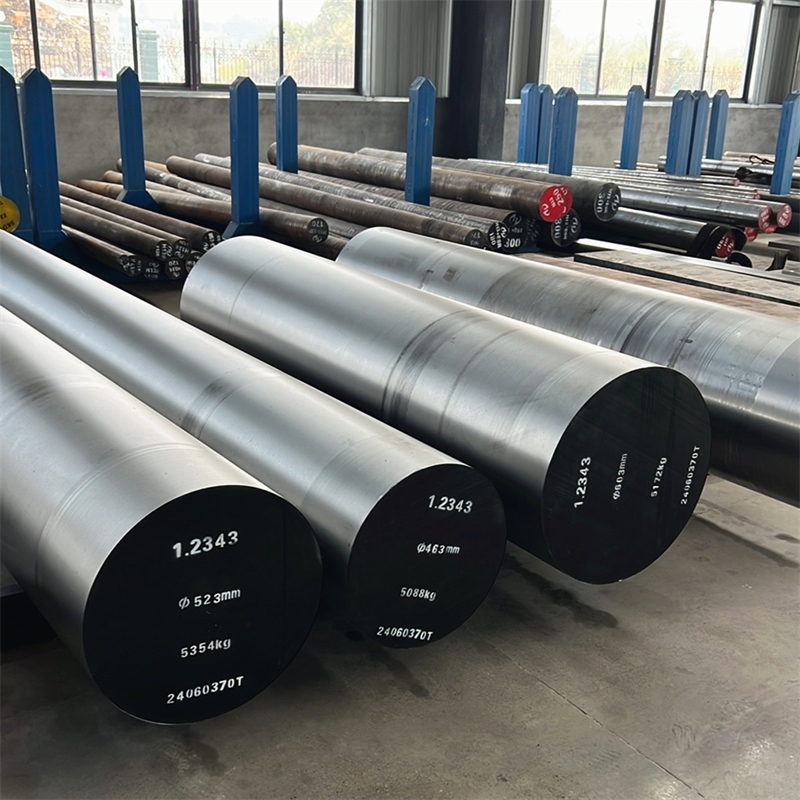

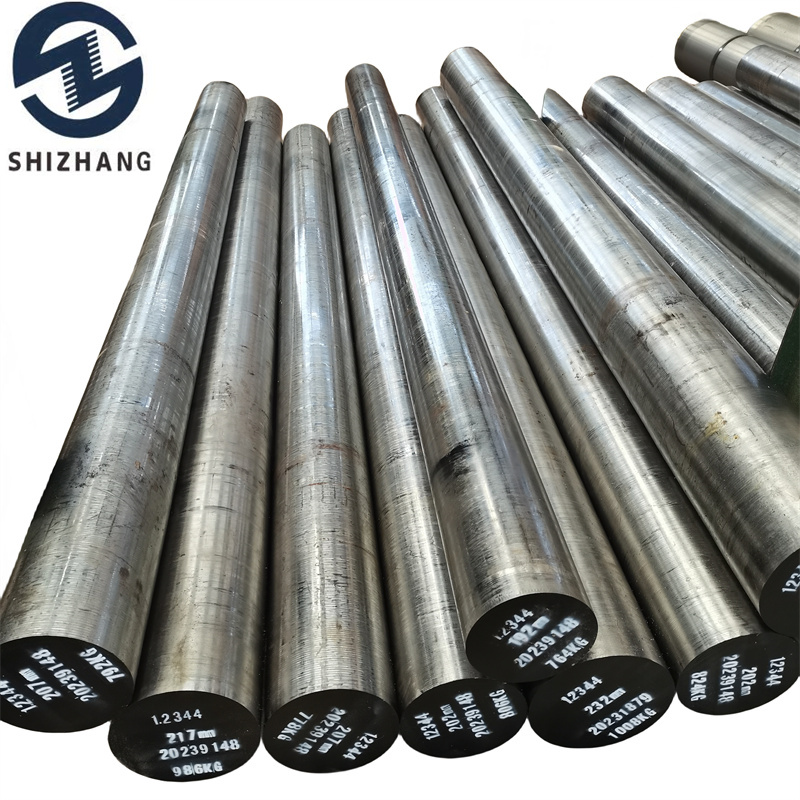

Size available:

Bars | Turned | Dia 20-800mm |

Black | Dia 20-800mm | |

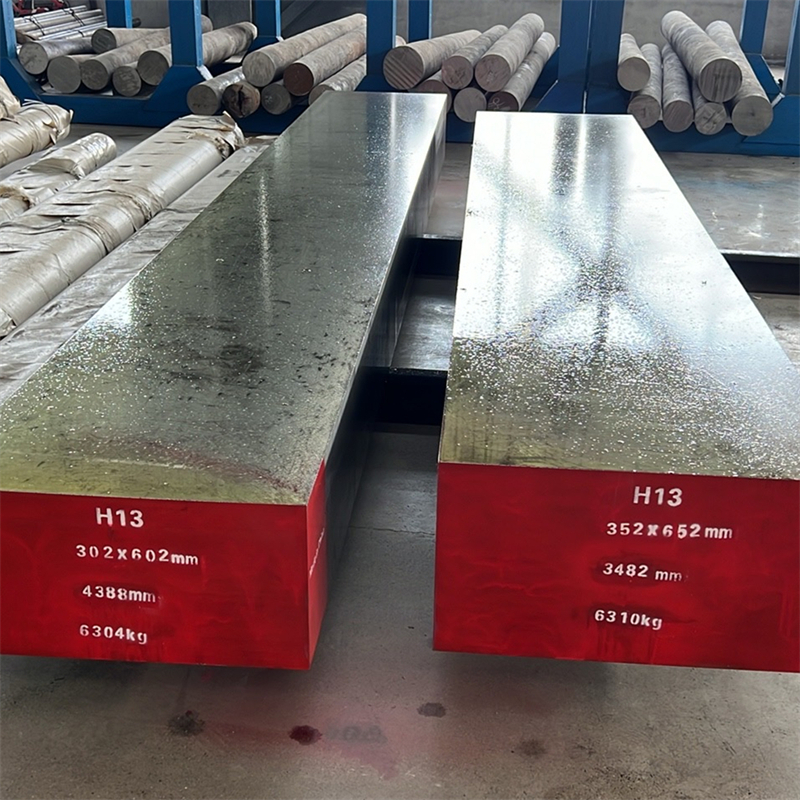

Flats | Milled | T:50-300 W: 200-710mm |

Black | T: 8-300 W: 200-710mm |