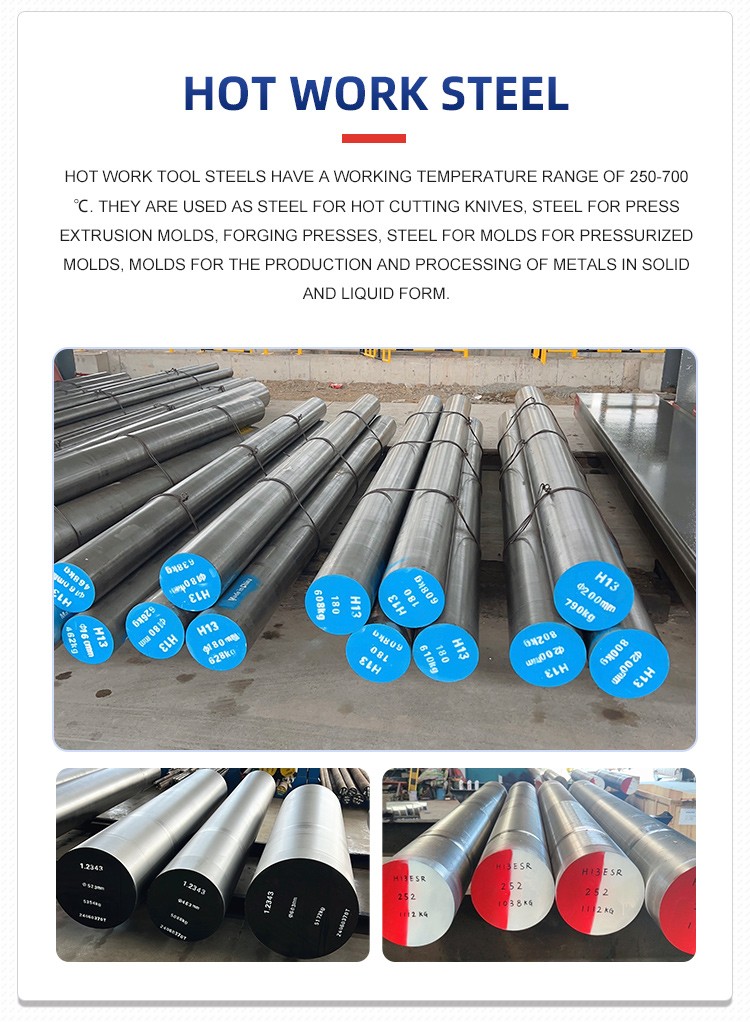

SKD61 Hot Work Die Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

SKD61 Hot Work Die Steel is a medium alloy hot work die steel containing silicon, chromium, molybdenum and vanadium. After quenching and tempering treatment, it obtains a martensitic structure with fine structure and moderate grains. It is basically distributed with fine carbides and has good properties. It has comprehensive mechanical properties and good hardenability, which is more suitable for manufacturing molds with large sizes and complex shapes.The corresponding foreign brand of SKD61 steel is 4Cr5MoSiV1 steel、DIN 1.2344、ASTM H13

Product Name: HOT WORK DIE STEEL---SKD61

Similar steel grades:

U.S.A | ASTM H13 |

German | X40CrMoV5-1(1.2344) |

Japan | SKD61 |

Austria | - |

Sweden | - |

China | 4Cr5MoSiV1 |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | V | Mo |

JIS G4404-2006 | 0.35-0.42 | 0.8-1.2 | 0.25-0.5 | ≤0.02 | ≤0.03 | 4.8-5.5 | 0.8-1.15 | 1-1.5 |

Principal Feature:

SKD61 Hot Work Die Steel is a medium alloy hot work die steel containing silicon, chromium, molybdenum and vanadium. After quenching and tempering treatment, it obtains a martensitic structure with fine structure and moderate grains. It is basically distributed with fine carbides and has good properties. It has comprehensive mechanical properties and good hardenability, which is more suitable for manufacturing molds with large sizes and complex shapes.

Typical Application:

SKD61 steel is suitable for hot work, aluminum, magnesium, zinc, copper alloy die-casting dies, grooving knives, scissors and hot forging actions, plastic molds, hot work reamers, rolling knives, general hot work forging dies, hot bolt dies, hot Various tools etc.

Heat Treatment:

sample quenching, preheating at 790±15℃, heating at 1000±6℃ (salt bath) or 1010±6℃ (furnace controlled atmosphere), holding for 5~15min, air cooling, and tempering at 550±6℃.

Size available:

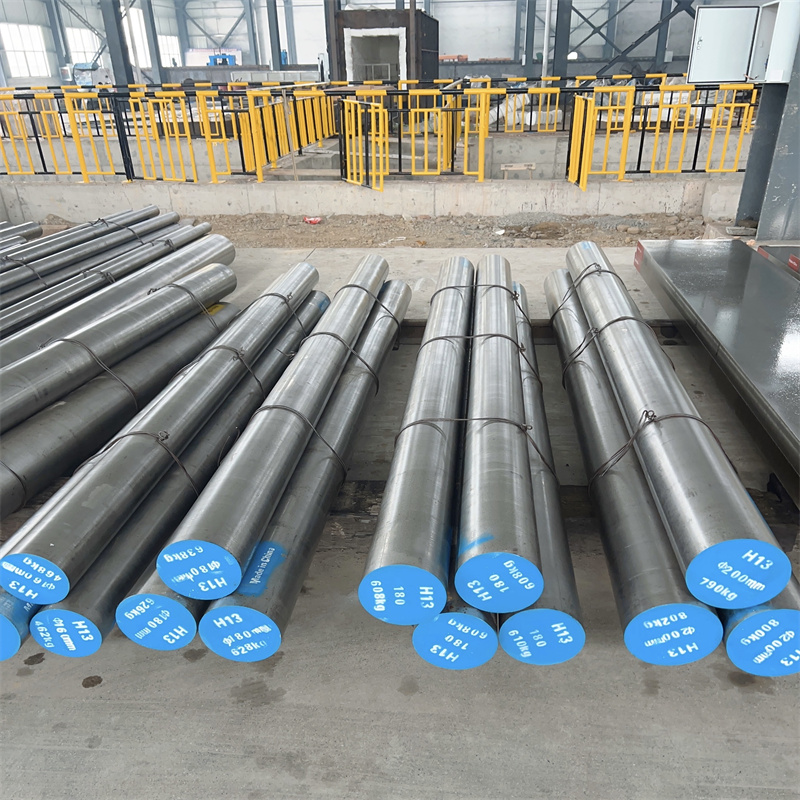

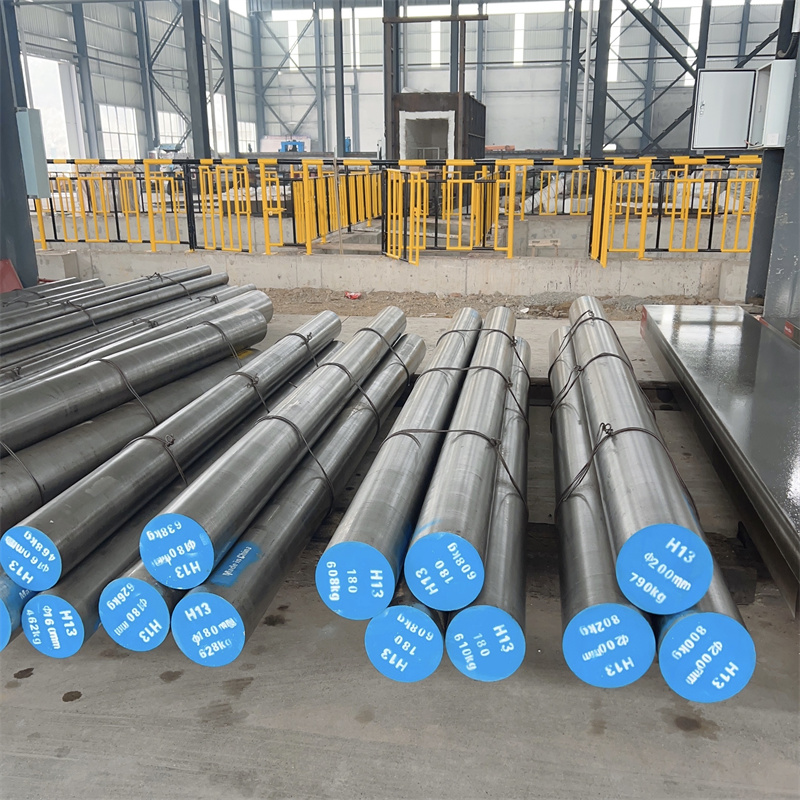

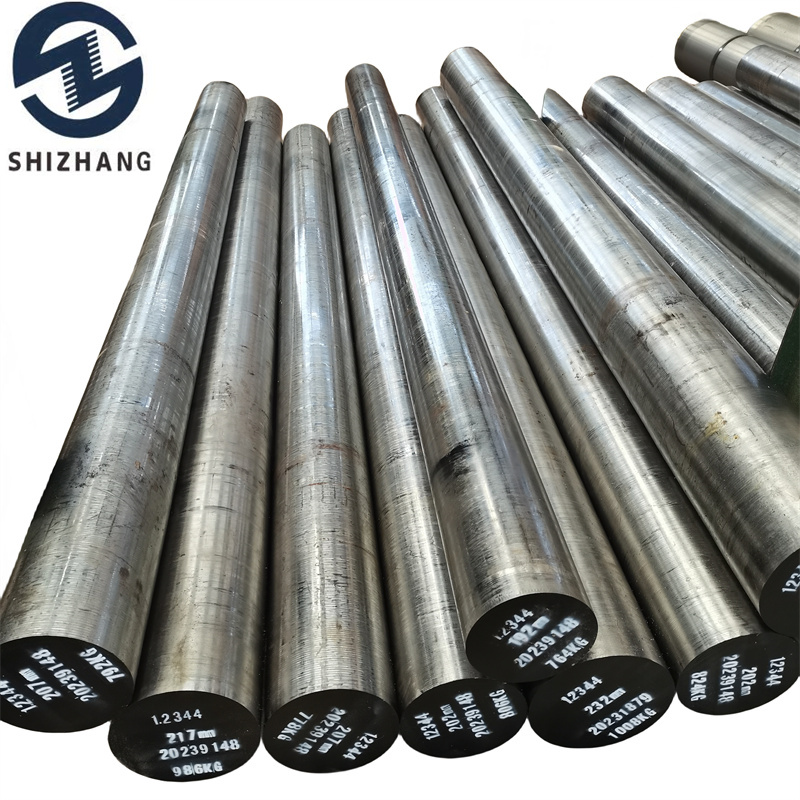

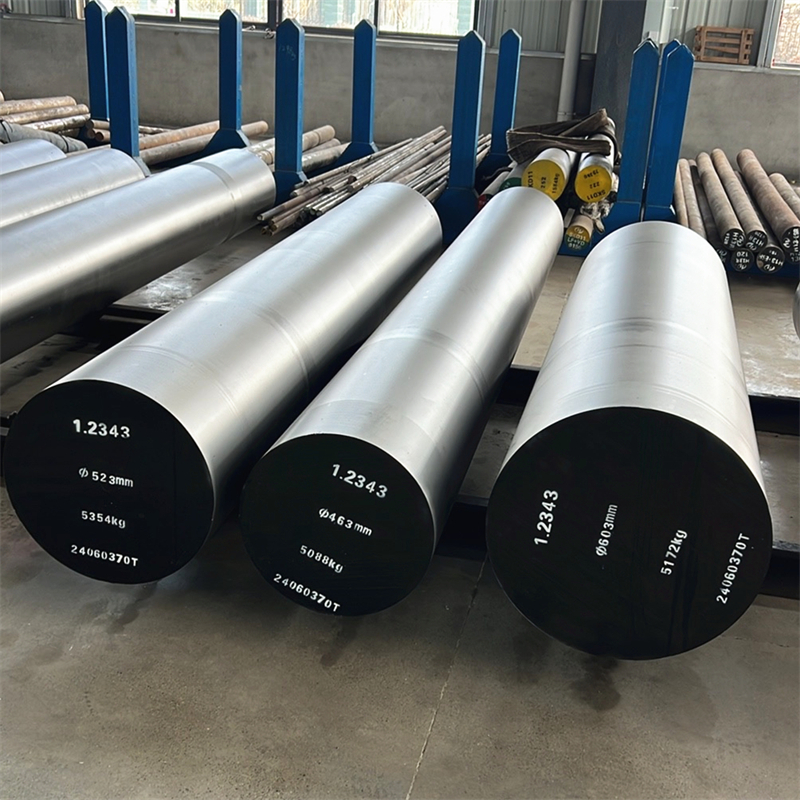

Bars | Turned | Dia 20-800mm |

Black | Dia 20-800mm | |

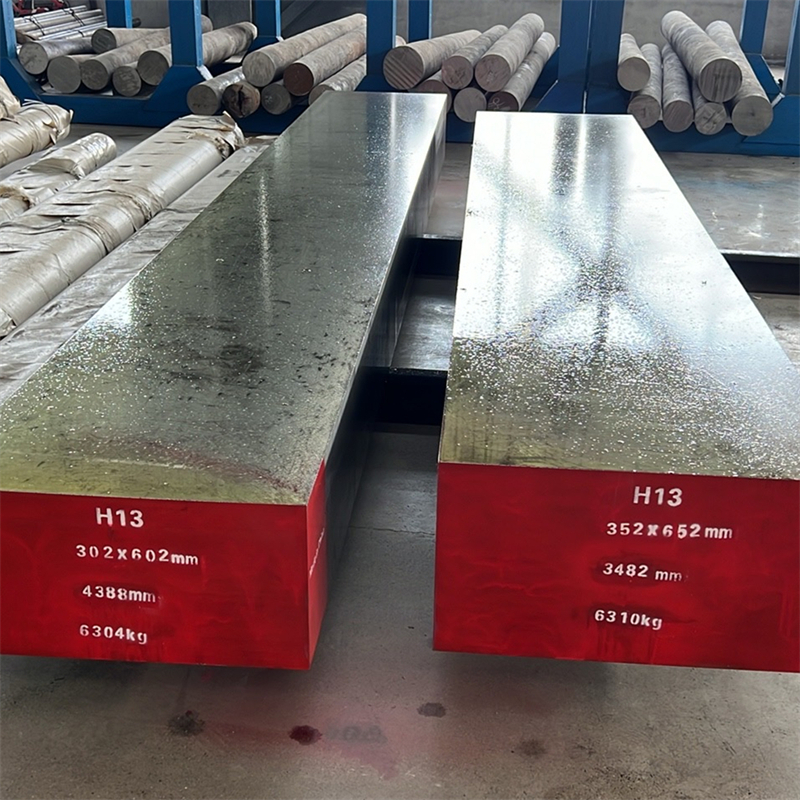

Flats | Milled | T:50-300 W: 200-710mm |

Black | T: 8-300 W: 200-710mm |