SCM440 Alloy Structural Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

Medium carbon chromium-molybdenum alloy steel SCM440, an alloy steel containing chromium and molybdenum. It has the advantages of stable composition, low harmful elements, high steel purity, small decarburization layer, and few surface defects. Easy to spheroidize and has low cold cracking rate. Alloy steel SCM440 is usually hardened and tempered. The ultimate tensile strength is 850-1000Mpa. This material strikes a very good balance between strength, toughness and wear resistance. The alloy's chromium content provides good hardness penetration, while the molybdenum element imparts average hardness and high strength.

Alloy steel SCM440 responds well to heat treatment and is easy to process under heat treatment conditions. This material offers many desirable properties such as good strength and wear resistance, excellent toughness, good ductility and resistance to high temperature stress.Our company can provide SCM440 hot-rolled or forged materials, etc.

Product Name:ALLOY STEEL---SCM440

Similar steel grades:

U.S.A |

|

German | - |

Japan | SCM440 |

Austria | - |

Sweden | - |

China | 42CrMo4 |

Chemical composition:

Standard | C | Si | Mn | S | P | Cu | Ni | Cr | Mo |

JIS G40 53-2008 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | ≤0.03 | ≤0.03 | ≤0.3 | ≤0.25 | 0.9-1.2 | 0.15-0.3 |

Principal Feature:

Medium carbon chromium-molybdenum alloy steel SCM440, an alloy steel containing chromium and molybdenum. It has the advantages of stable composition, low harmful elements, high steel purity, small decarburization layer, and few surface defects. Easy to spheroidize and has low cold cracking rate. Alloy steel SCM440 is usually hardened and tempered. The ultimate tensile strength is 850-1000Mpa. This material strikes a very good balance between strength, toughness and wear resistance. The alloy's chromium content provides good hardness penetration, while the molybdenum element imparts average hardness and high strength.Alloy steel SCM440 responds well to heat treatment and is easy to process under heat treatment conditions. This material offers many desirable properties such as good strength and wear resistance, excellent toughness, good ductility and resistance to high temperature stress.

Typical Application:

JIS SCM440 is a commonly used steel type for the production of high-strength fasteners. The product has the advantages of stable composition, low harmful elements, high steel purity, small decarburization layer, and few surface defects. JIS SCM440 is easy to undergo spheroidizing annealing and cold heading cracking during use. Low rate, stable heat treatment quality, uniform hardness, widely used in engines, molds and other industries。

Heat Treatment:

Heat treatment specifications: 880℃, 1h oil quenching, 650~680℃, 2h tempering, air cooling.

Metallographic structure: tempered martensite.

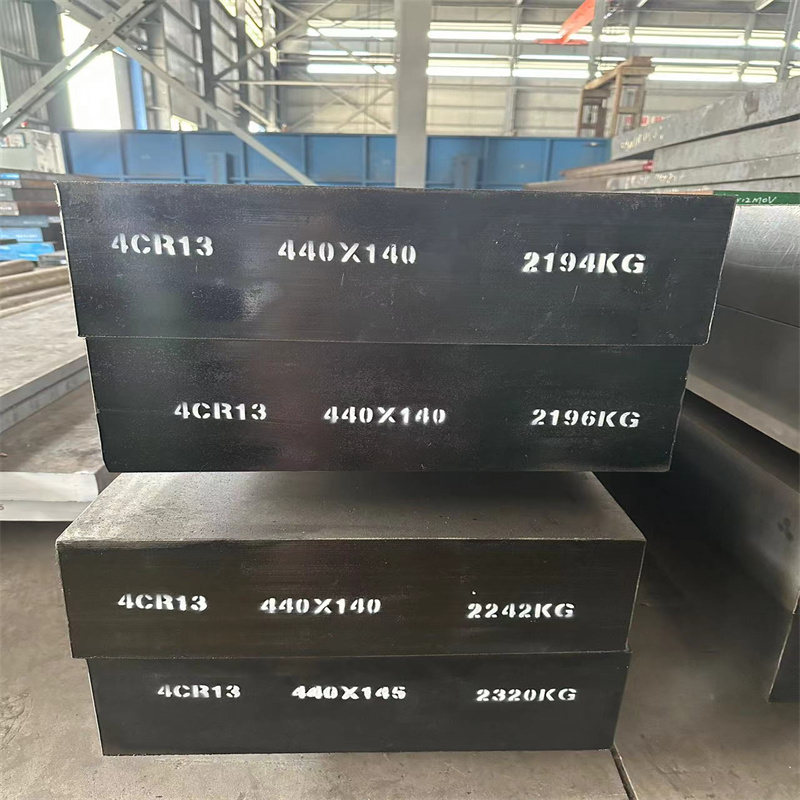

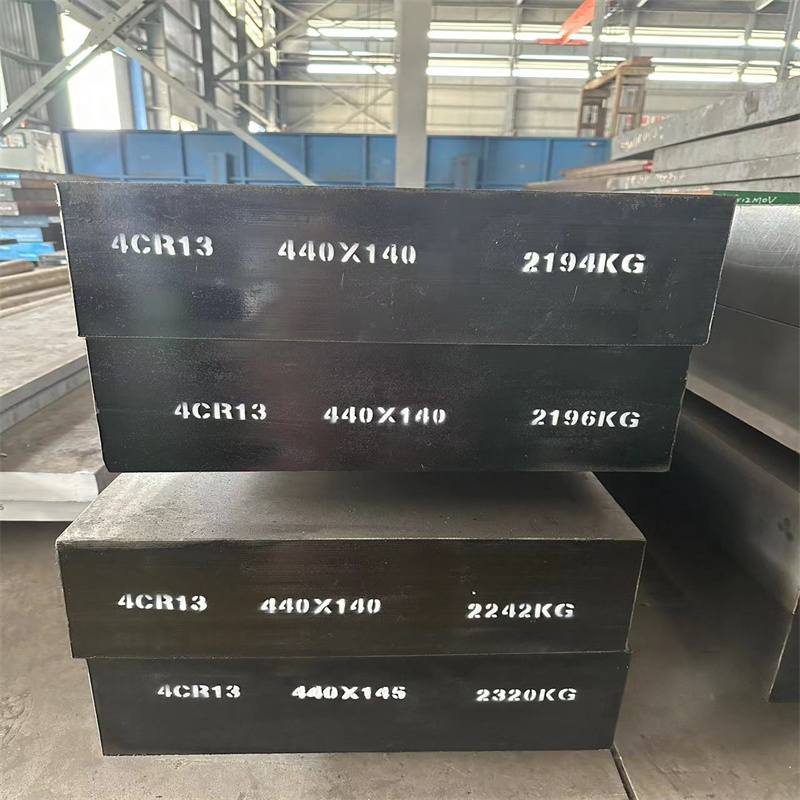

Size available:

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |