Alloy Steel

-

Alloy Steel 9Cr18

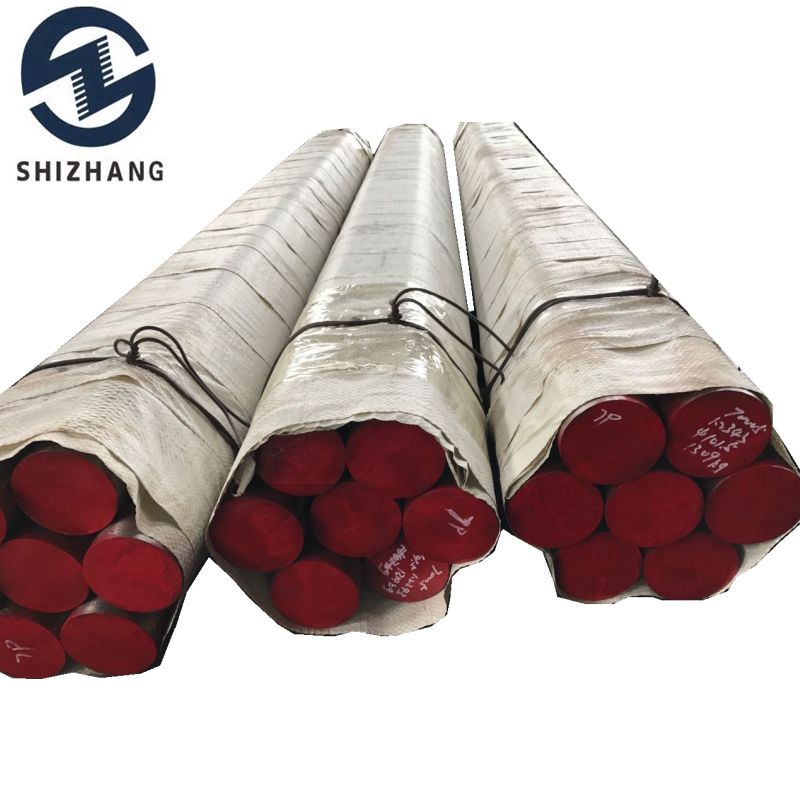

9Cr18 steel is a high-carbon, high-chromium martensitic stainless steel that has high hardness, high wear resistance and corrosion resistance after quenching. This steel is suitable for manufacturing plastic molds that withstand high wear resistance, high load and corrosive media. It is commonly used as stainless slicing mechanical cutting tools and shearing tools, surgical blades, high wear-resistant equipment parts, etc.Our company provides 9Cr18 cold-drawn round stainless steel,9Cr18 wire rod stainless steel, 9Cr18 alloy steel hot-rolled round steel, and 9Cr18alloy steel hot-rolled steel plates.

Email Details -

T7 Carbon Tool Steel

T7 steel has good toughness and hardness, but poor cutting ability; it is mostly used to manufacture tools that require greater toughness and a certain hardness but do not require very high cutting ability

Email Details -

T8 Alloy & Tool Steel

T8 is a carbon tool steel; hardened plastic mold steel. After quenching and tempering, it has high hardness and wear resistance, but low hot hardness, poor hardenability, easy deformation, low plasticity and strength

Email Details -

T9 Alloy Steel

T9 tool steel is a high carbon tool steel, cold die steel, carbon content of 0.6% or more of high carbon steel, the steel has high hardness and wear resistance, toughness

Email Details -

T10 Alloy & Tool Steel

T10 steel is a high carbon tool steel with good hardness and wear resistance. It is suitable for making cutting tools and stamping dies. Its advantages include moderate hardness, strong toughness, low production cost, after heat treatment hardness can reach more than 60HRC. However, the hardenability of T10 Steel is low, heat resistance is poor, in the quenching heating is not easy to overheat, still maintain fine grain. In addition, toughness, strength and wear resistance are higher than T7-T9, but the thermal hardness is low, hardenability is still not high, quenching deformation

Email Details -

T11 Alloy & Tool Steel

T11 steel is a kind of low hardenability cold working die steel and high carbon steel with 0.6% carbon. The steel has the advantages of good machinability, high hardness and toughness, but low hardenability and large quenching deformation. Because the steel contains less alloy elements, low tempering resistance, shallow hardening layer, and therefore low load-bearing capacity. With high hardness and wear resistance, grain growth sensitivity is small. The state of supply is hardness ≤207HBW

Email Details -

T12 Alloy Steel

T12 is a carbon tool steel, due to the high carbon content, more excess carbide after quenching, according to wear resistance and hardness suitable for making tools that are not affected by impact load, cutting speed is not high, and cutting edge is not hot.

Email Details -

T13A Alloy & Tool Steel

T13A carbon is the steel with the highest carbon content among carbon tool steels. It has extremely high hardness and excellent wear resistance, but its mechanical properties are relatively low, making it unable to withstand impact.

Email Details -

8MnSi Alloy & Tool Steel

8MnSi steel is alloy tool steel and cold working die steel. The steel conforms to China's resources, because it does not contain chromium and the price is low, its hardenability, toughness and wear resistance are better than carbon tool steel. On the basis of carbon tool steel T8, the content of silicon and manganese is increased. Due to the increased content of silicon and manganese, the hardenability of the steel is improved

Email Details