Alloy Steel 9Cr18

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

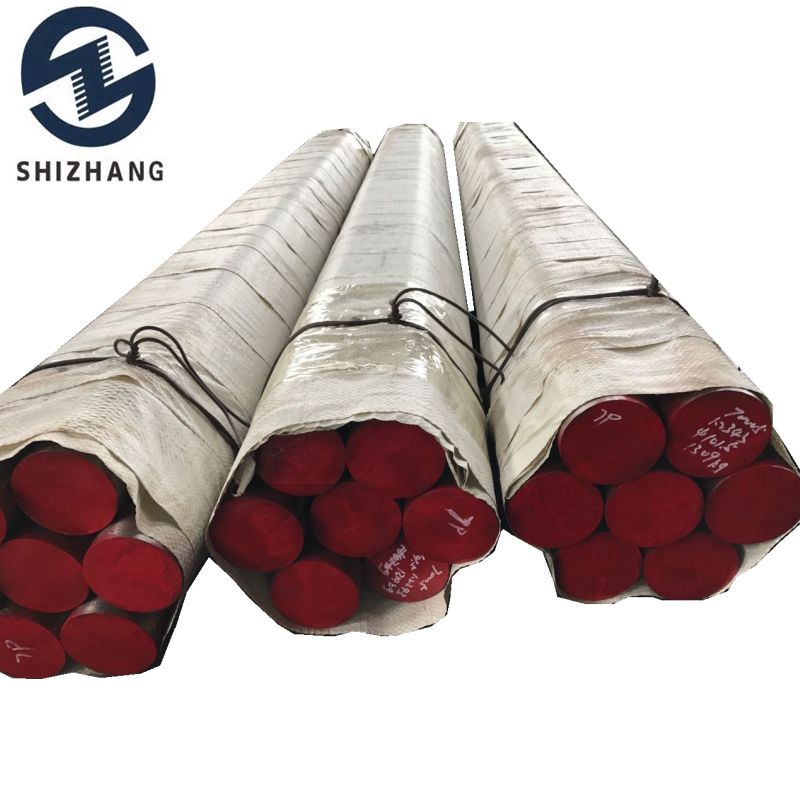

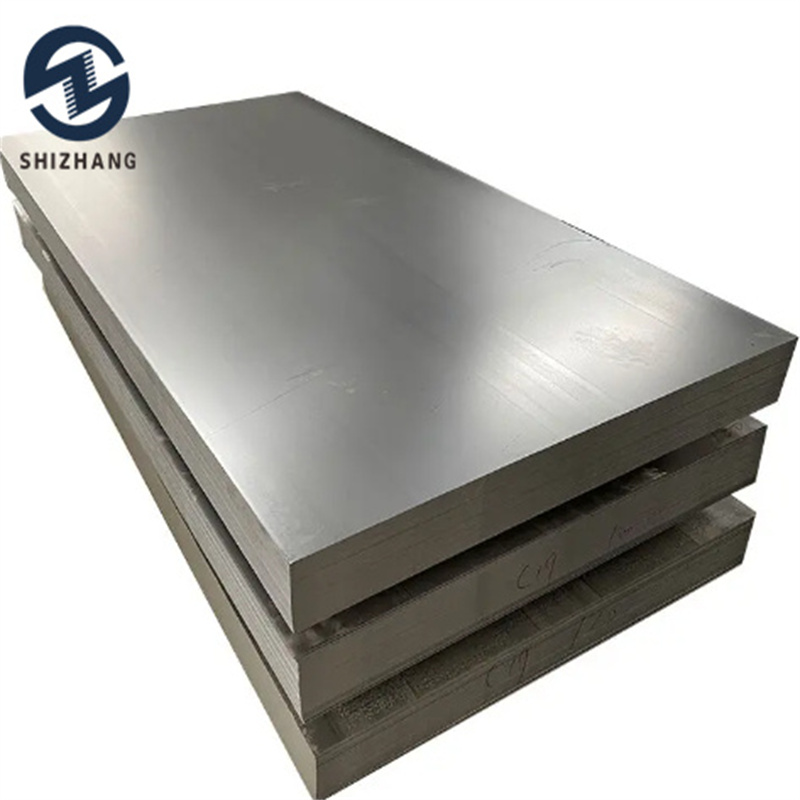

9Cr18 steel is a high-carbon, high-chromium martensitic stainless steel that has high hardness, high wear resistance and corrosion resistance after quenching. This steel is suitable for manufacturing plastic molds that withstand high wear resistance, high load and corrosive media. It is commonly used as stainless slicing mechanical cutting tools and shearing tools, surgical blades, high wear-resistant equipment parts, etc.Our company provides 9Cr18 cold-drawn round stainless steel,9Cr18 wire rod stainless steel, 9Cr18 alloy steel hot-rolled round steel, and 9Cr18alloy steel hot-rolled steel plates.

Product Name: ALLOY STEEL---95Cr18

Similar steel grades:

U.S.A | - |

German | - |

Japan | - |

Austria | - |

Sweden | - |

China | 9Cr18 |

Chemical composition:

Standard | C | Si | Mn | Cr | Ni | P | S | Mo |

GB/T 1220-1992 | 0.90~1.00 | ≤0.80 | ≤0.80 | 17.00~19.00 | ≤0.60 | ≤0.035 | ≤0.030 | ≤0.75 |

Principal Feature:

9Cr18 steel is a high-carbon, high-chromium martensitic stainless steel that has high hardness, high wear resistance and corrosion resistance after quenching.

Typical Application:

95Cr18 alloy steel is a martensitic stainless steel, also known as 440C stainless steel. It is widely used in fields such as slicing machinery cutting tools, shearing tools, surgical blades and high wear-resistant equipment parts..

Heat Treatment:

Annealing, slow cooling at 800~920℃;

Quenching, oil cooling at 1000~1050℃;

Tempering, oil or air cooling at 200~300℃.

Metallographic structure: The structure is characterized by martensite type.

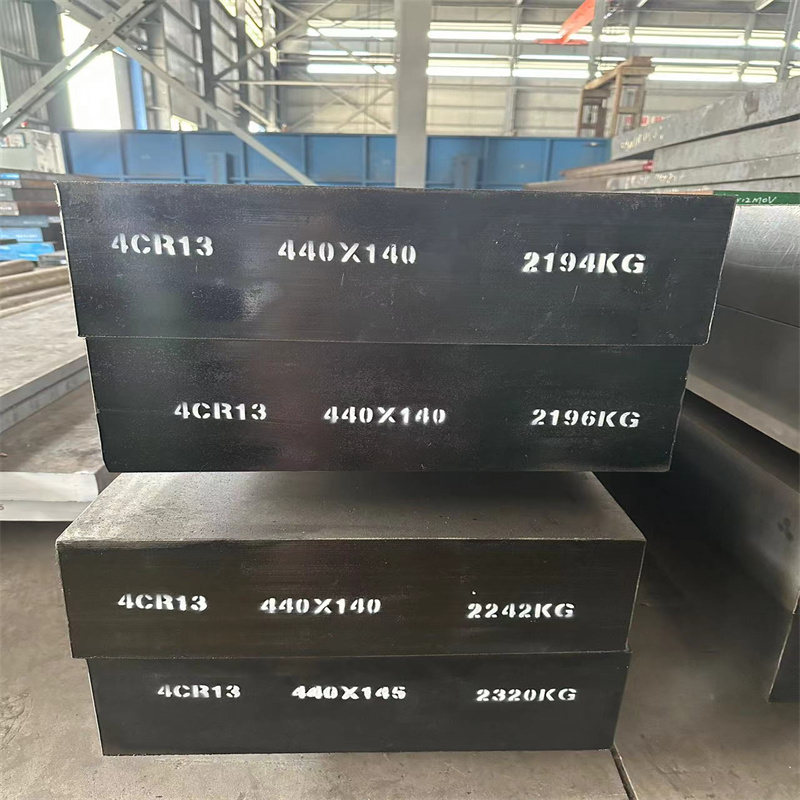

Size available:

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |