AISI P20+S Plastic Mould Steel

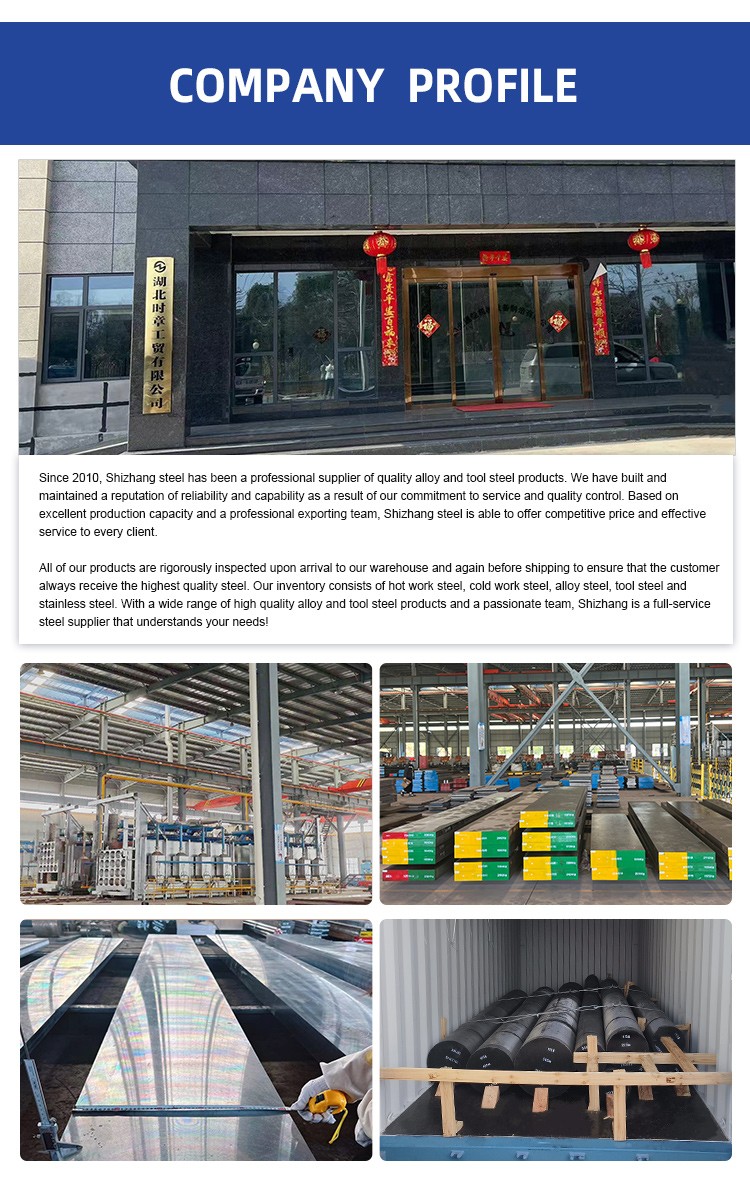

- Shizhang Steel

- China

- 7-30days

- 500 Tons/Month

AISI P20+S steel is a high-quality low-alloy wear-resistant steel that is widely used in the manufacturing of various wear-resistant precision mold tools and plastic moulding. AISI P20+S has good chemical stability and corrosion resistance, which can effectively prevent rust and corrosion.P20+S special steel is a high-strength alloy tool steel,and The corresponding foreign brand of AISI P20+S is DIN 1.2312、40CrMnMoS8-6.

Product Name:Plastic Mould Steel --- AISI P20+S

Similar Steel Grades:

U.S.A | AISI P20+S |

German | DIN 1.2312 |

Japan | -- |

Sweden | -- |

China | 40CrMnMoS8-6 |

Chemical Composition(%) :

C | Si | Mn | Cr | Mo | P | S |

0.35-0.45 | 0.30-0.50 | 1.40-1.60 | 1.80-2.00 | 0.15-0.25 | ≤0.03 | 0.05-1.10 |

Principal Feature:

AISI P20+S steel with excellent machinability properties because of the high S content, good toughness properties,good wear resistance, uniform hardness in all dimensions, dimensional stability, requiring no heat treatment, 280 - 325HB hardened and tempered condition, suitable for nitriding to increase wear resistance, not suitable for chrome plating,polishing and etch graining.

Typical Application:

AISI P20+S Suitable for large-scale long-life plastic injection mold, such as home appliances, computer case etc.

surface finish of plastic products mold; blow mold;Due to high hardness, P20+S special steel can be used for the slider of plastic mold, forming tools, structural parts and shaft.

Heat Treatment:

Forge: at 850℃-1050℃ Cool slowly and anneal immediatedly

Anneal: at 740℃-760℃ Cool slowly in furnace

Stress Relieve: at to 600℃-650℃ Cool in still air

Harden: Preheat at 580℃-680℃ raise to 850℃-880℃ Cool in air, oil or into salt bath held at 50℃-100℃ and then air cool

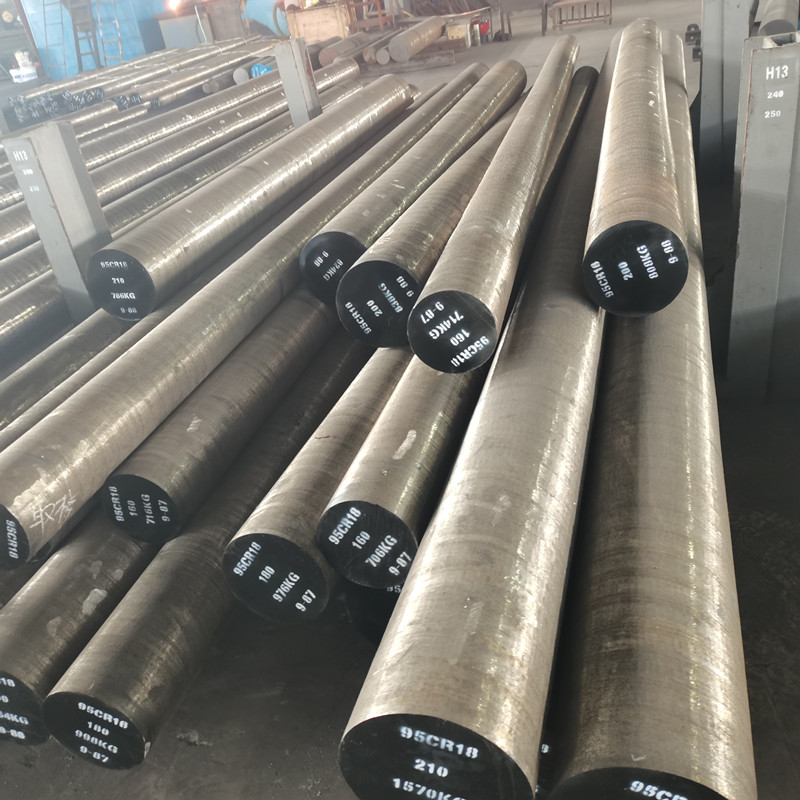

Size Available:

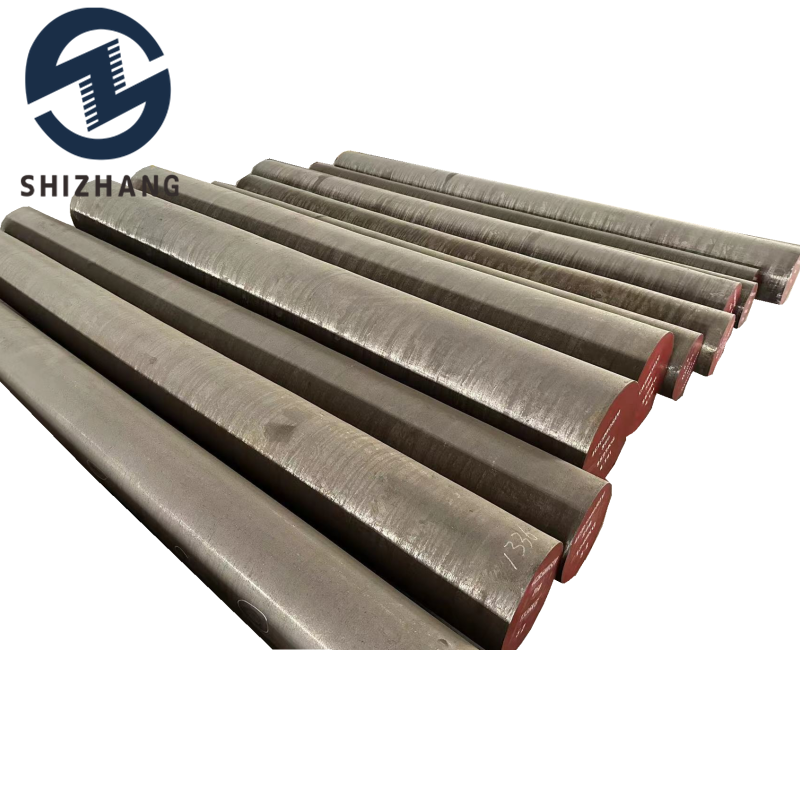

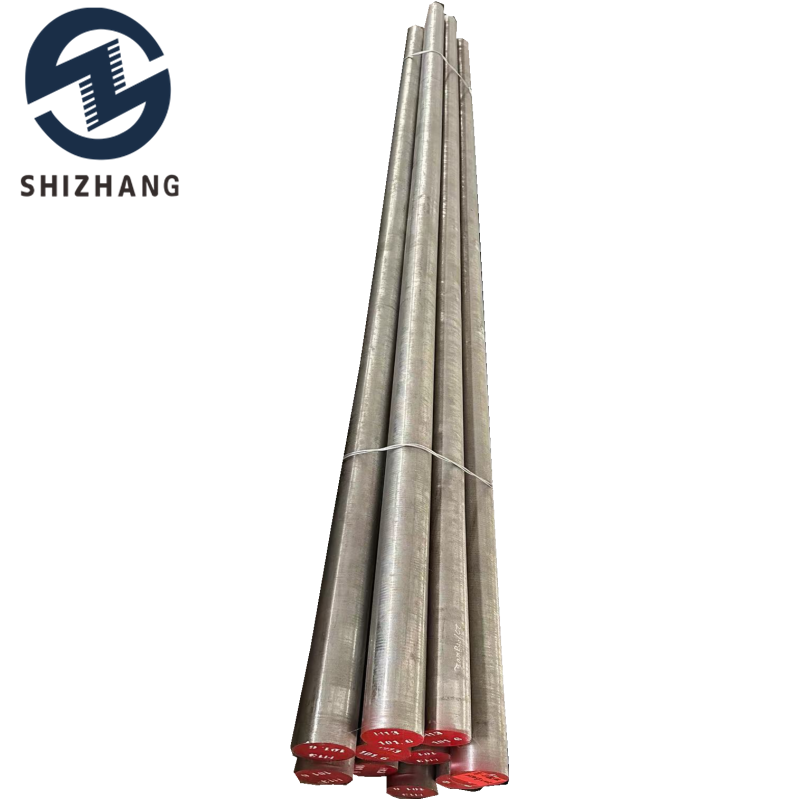

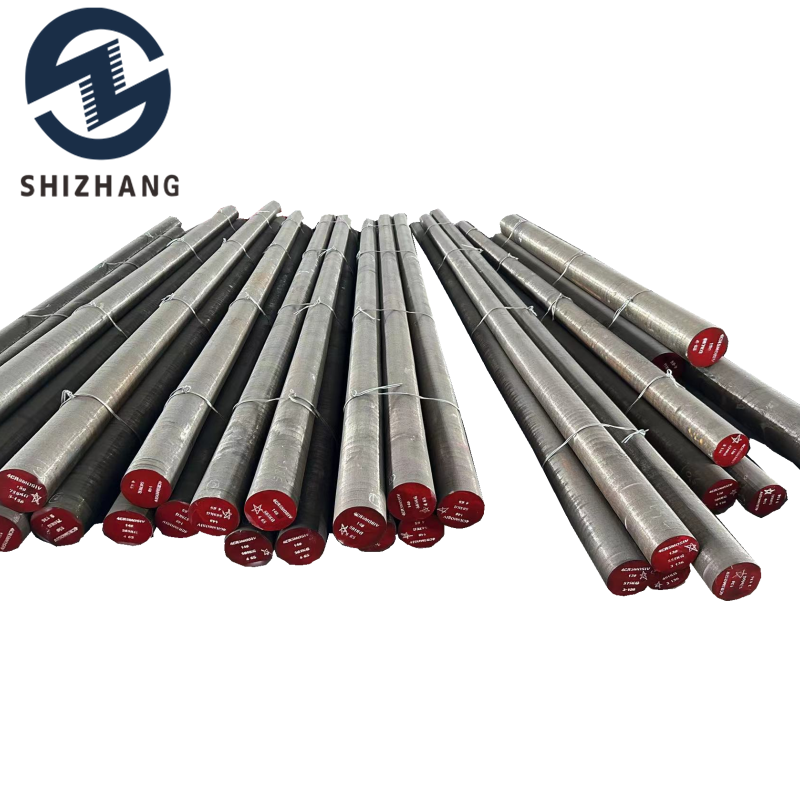

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |