1.2312 Plastic Mold Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

DIN 1.2312 steel has maintained high quality and low sulfur content since its production. Therefore, the material has good polishing and photo-etching properties, good processing performance, high purity, excellent uniformity and reliable uniform hardness. The characteristics of DIN 1.2312 tool steel are: the material hardness of large cross-section is relatively uniform and balanced; excellent cutting performance; high compressive strength; wear resistance; good corrosion resistance; suitable for making large plastic molds

Product Name: PLASTIC MOULD STEEL---1.2312

Similar steel grades:

U.S.A | P20+S |

German | DIN 1.2312 |

Japan | - |

Austria | - |

Sweden | - |

China | 40CrMnMoS86 |

Chemical composition:

Standard | C | Si | Mn | S | Cr | Mo | P |

DIN EN ISO 4957-2018 | 0.35-0.45 | 0.30-0.50 | 1.40~1.60 | 0.05-0.10 | 1.80~2.0 | 0.15~0.25 | ≤0.030 |

Principal Feature:

DIN 1.2312 steel has maintained high quality and low sulfur content since its production. Therefore, the material has good polishing and photo-etching properties, good processing performance, high purity, excellent uniformity and reliable uniform hardness. The characteristics of 1.2312 tool steel are: the material hardness of large cross-section is relatively uniform and balanced; excellent cutting performance; high compressive strength; wear resistance; good corrosion resistance; suitable for making large plastic molds.

Typical Application:

Main applications of 1.2312 tool steel: especially suitable for thermoplastic corrosion plastics; suitable for small molds; suitable for transparent and mirror products and molds; extrusion molds for thermoplastic plastics.

Heat Treatment:

Heat treatment process of quenching (860-880℃ water cooling or oil cooling) and tempering (150-200℃).

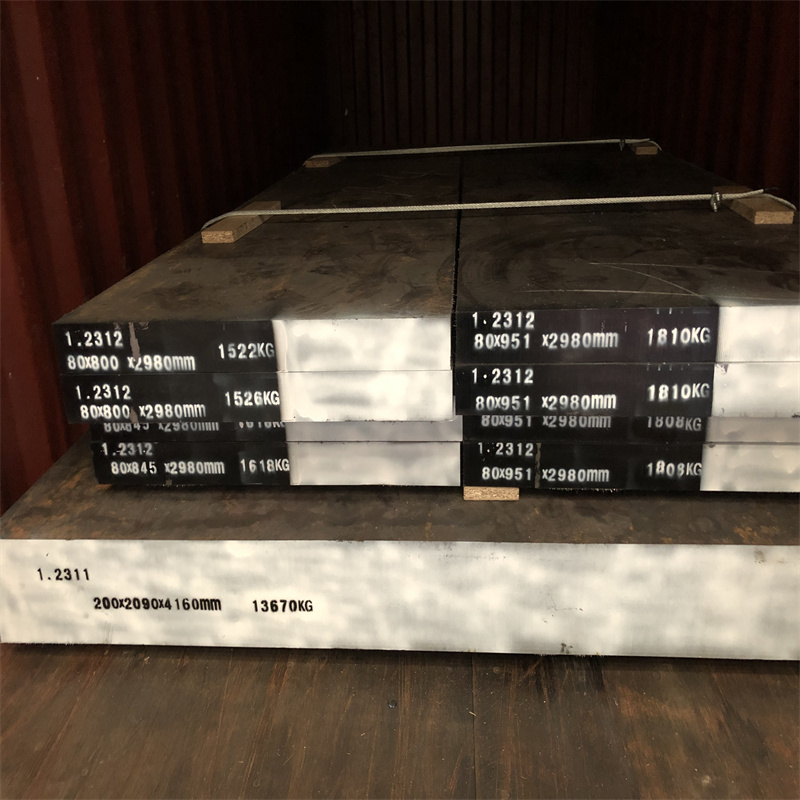

Size available:

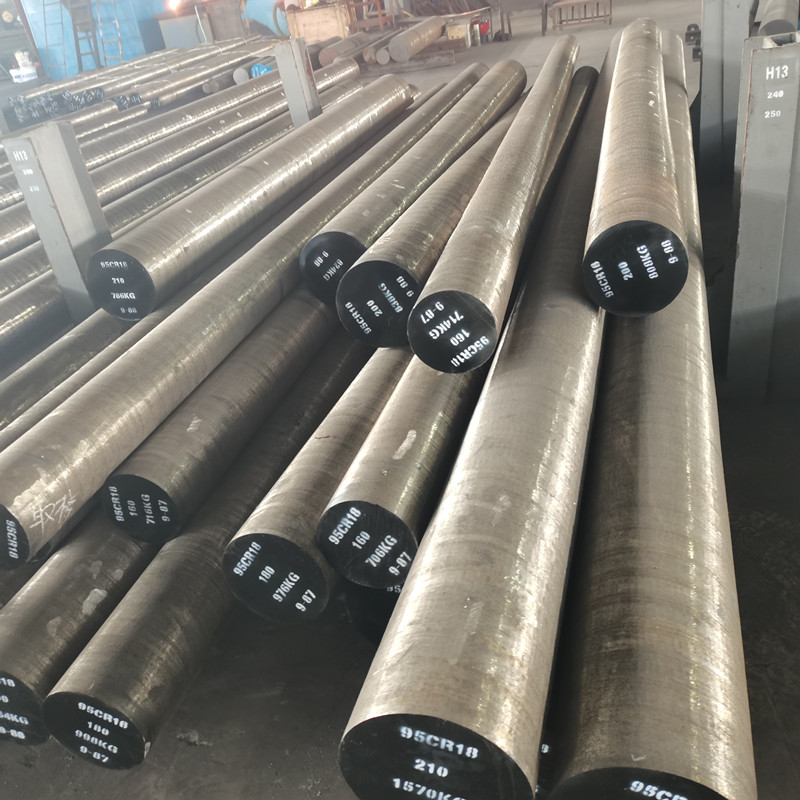

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

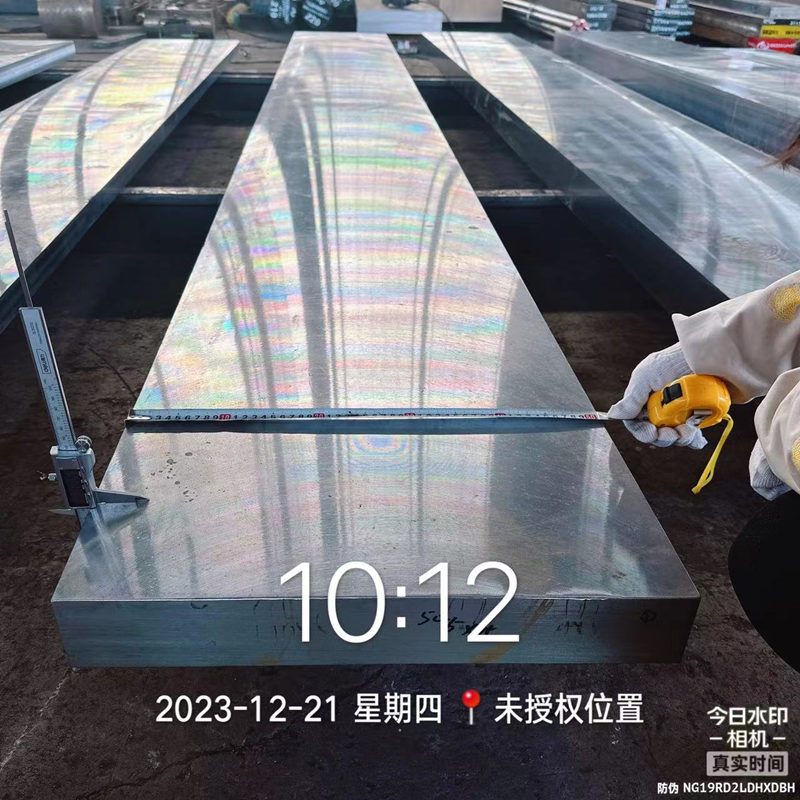

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |