1.2316 Plastic Mold Steel

- Shizhang Steel

- China

- 15-45

- 500 Tons/Month

1.2316 steel is mainly used for plastic injection molds, in connection with chemically aggressive and acidic plastics such as thermoplastics and for PVC-arminoplastics, extrusion tools, compressor parts and for special machine parts in the food industry.Our company are 1.2316 tool steel suppliers

Product Name: PLASTIC MOULD STEEL---1.2316

Similar steel grades:

U.S.A | - |

German | 1.2316 / X38CrMo16 |

Japan | - |

Sweden | - |

China | 3Cr17NiMo |

Chemical composition: (%)

Grade | C | Si | Mn | Cr | Mo | Ni | P | S |

1.2316 | 0.33-0.45 | 1.00max | 1.00max | 16.00-17.00 | 1.00- 1.30 | 0.60- 1.00 | 0.03max | 0.03max |

Principal Feature:

1) pure and precision mirror polishing

2) strong corrosion resistance and its pitting corrosion goes beyond S-136 and 1.2316

3) convinient heat treatment

4) quenched and tempered steel after pre-handed, its dimension become more stable

5) Its resistance is as good as S-136 and 1.2316, and easy to repair welding.

Quenched hardness: 42-49 HRC

Typical Application:

1.2316 steel can be used for Extrusion dies and die-casting for aluminum, Mandgnesium allay mostly, for copper alloy could use, Mechanical press forging of steel, could use also. Suitable steel for making plastic mould which requires of corrosion resistance and abrasion, or for plastic mould separates out from acid during process, such as CA, POM products.

Heat Treatment:

Forge: at 900℃-1000℃ Cool slowly and anneal immediatedly

Anneal: at 780℃-820℃ Cool slowly in furnace

Stress Relieve: at to 600℃-650℃ Cool in still air

Harden: Preheat at 600℃-700℃ raise to 1000℃-1040℃ Cool in air, iol or into salt bath held at 500℃-550℃ and then air cool

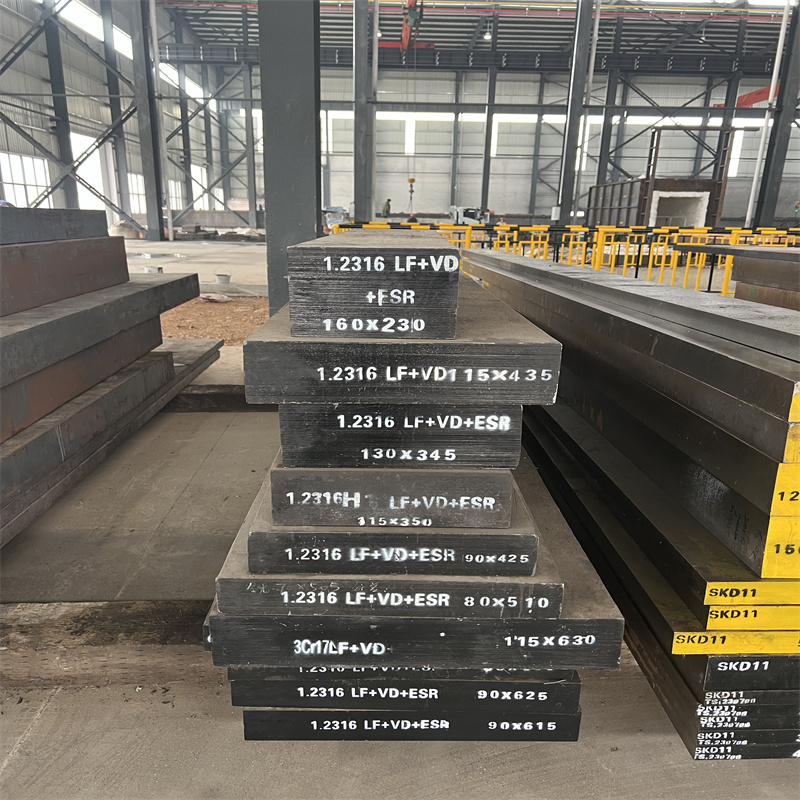

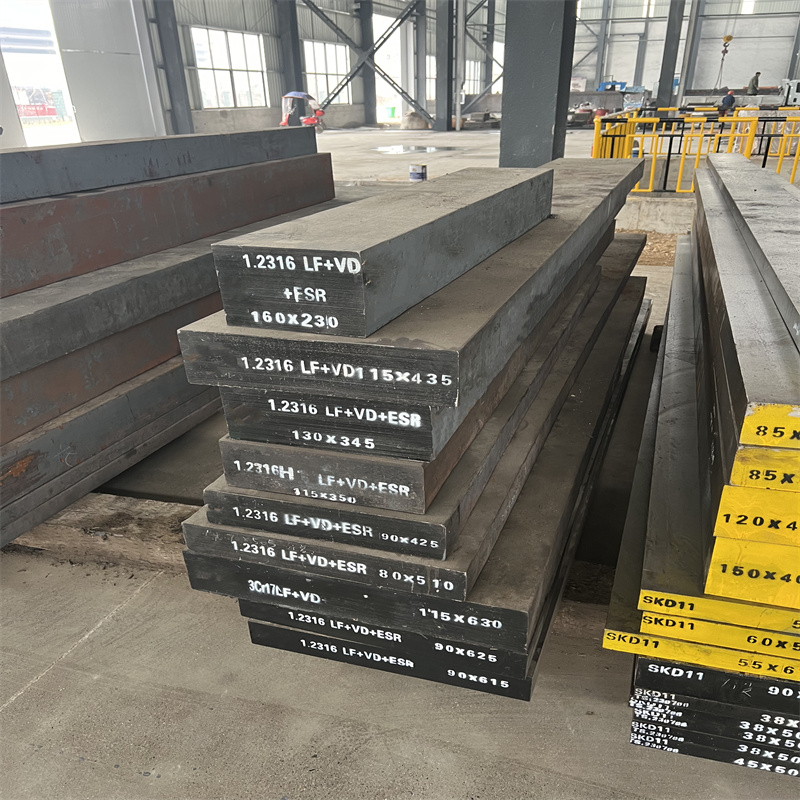

Size available:

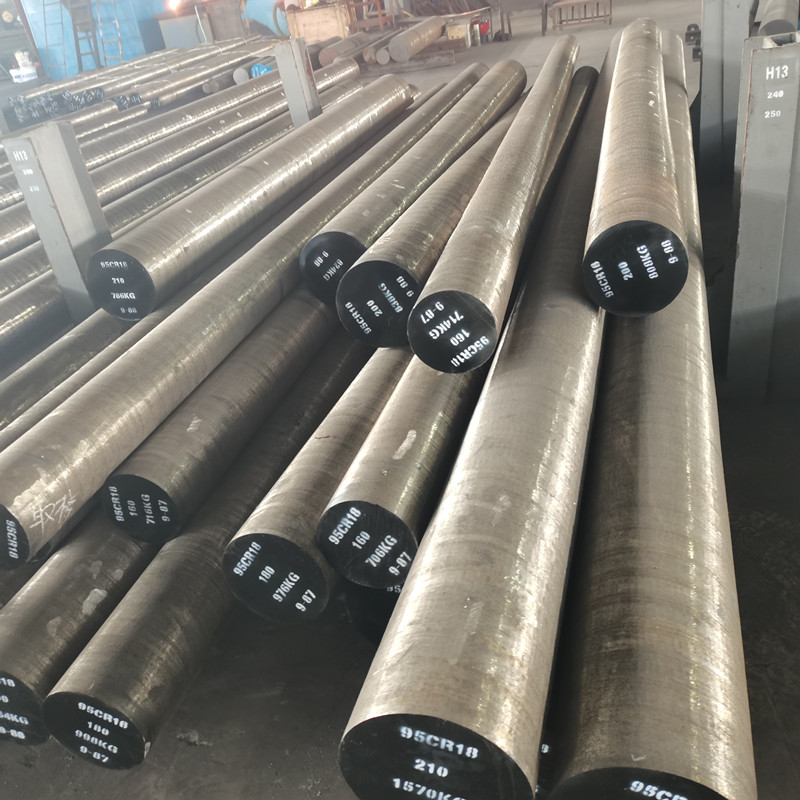

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |