P20 Plastic Mold Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

P20 steel is American AISI standard pre-hardened plastic mold steel. P20 tool steel has good machining performance, excellent polishing performance, certain toughness, and can be carburized. After carburizing and quenching, the surface hardness can reach 65HRC, and has high thermal resistance. Hardness and wear resistance.

Product Name: Plastic Mould Steel ---P20

Similar steel grades:

U.S.A | AISI P20 |

German | DIN 1.2311 |

Japan | - |

Austria | - |

Sweden | 618 |

China | 3Cr2Mo |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | Mo |

GB/T 1299-1985 | 0.28~0.40 | 0.20~0.80 | 0.60~1.00 | ≤0.03 | ≤0.03 | 1.40~2.00 | 0.30~0.55 |

Principal Feature:

P20 tool steel is American AISI standard pre-hardened plastic mold steel. P20 tool steel has good machining performance, excellent polishing performance, certain toughness, and can be carburized. After carburizing and quenching, the surface hardness can reach 65HRC, and has high thermal resistance. Hardness and wear resistance.

Typical Application:

P20 steel is suitable for plastic molds and mold bases such as TV front casings, telephones, water dispensers, vacuum cleaners; thermoplastic injection molds, extrusion molds; thermoplastic blow molds; main parts of heavy-duty molds; cold structural parts; commonly used Used in manufacturing TV casings, washing machines, refrigerator inner casings, buckets, etc..

Heat Treatment:

Steel ingot: heating temperature 1180~1200°C, starting temperature 1130~1150°C, ending temperature ≥850°C, pit cooling.

Steel billet: heating temperature 1120~1160°C, starting temperature 1070~1110°C, ending temperature ≥850°C, sand cooling or slow cooling

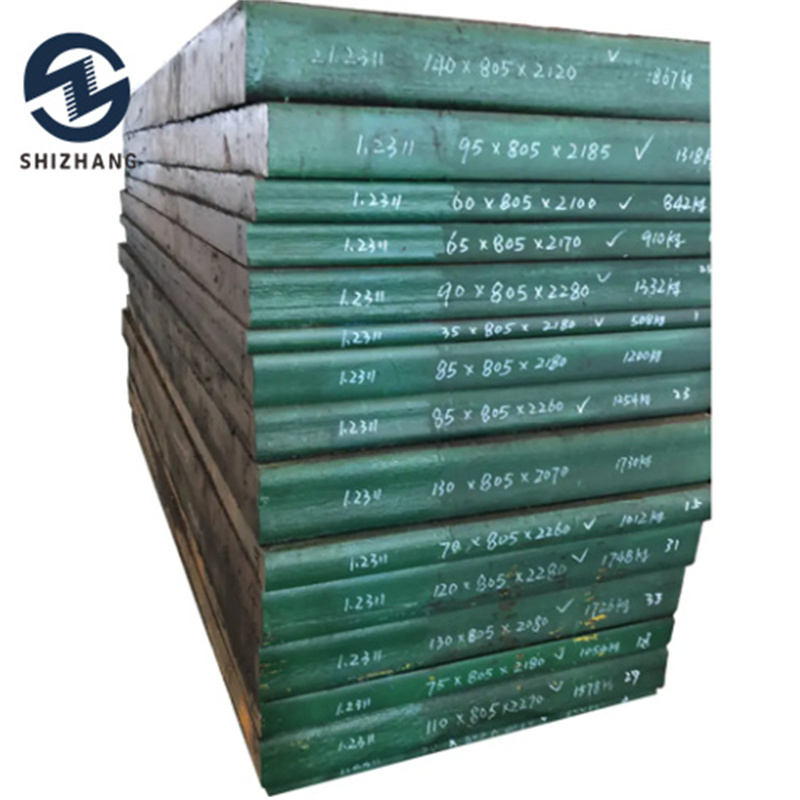

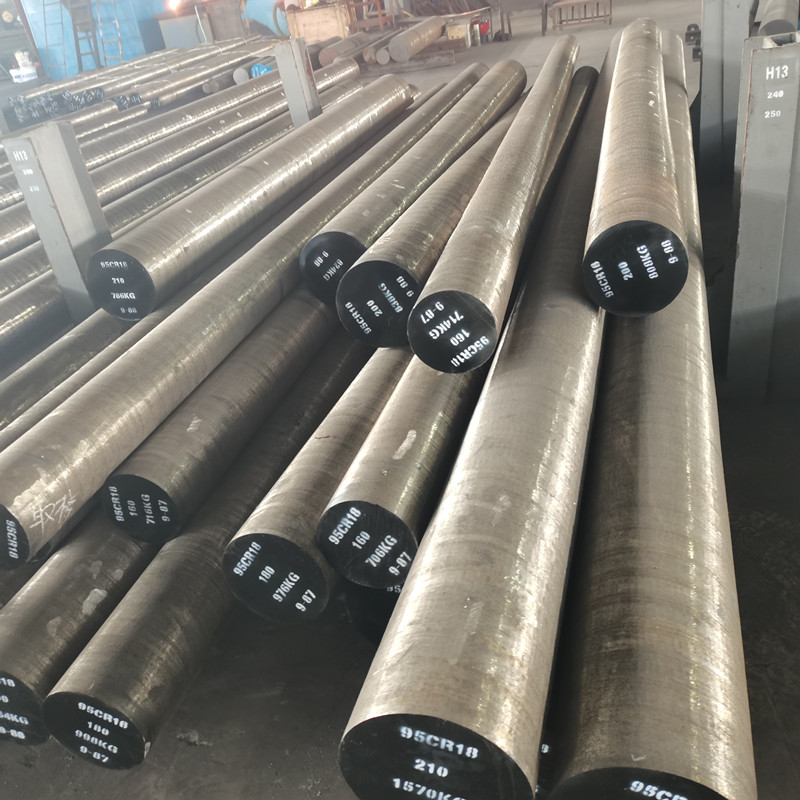

Size available:

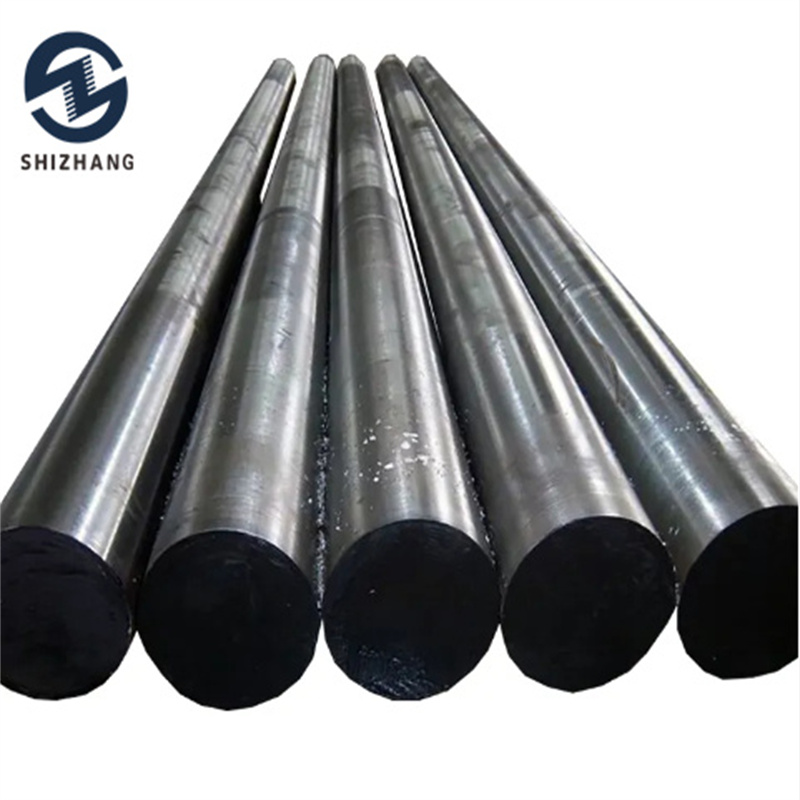

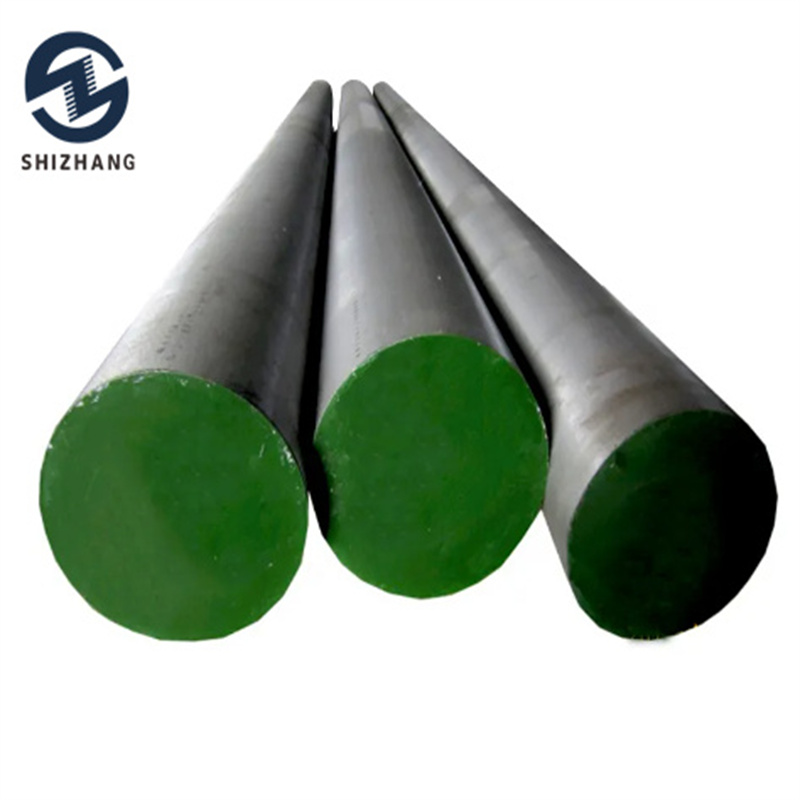

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |