1.2311 Plastic Mold Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

German mold steel 1.2311 . This steel is produced through an "ultra-pure" process and is pre-hardened. 1.2311 steel shows a high degree of micro-purity and excellent homogeneous structure, excellent polishability and photo-etching properties. After heat treatment, DIN 1.2311 tool steel has good processing and polishing properties, can be nitrided, and is suitable for surface treatments such as chrome plating. The material has uniform hardness (up to 400mm thick), good toughness, and good machining performance

Product Name: PLASTIC MOULD STEEL---1.2311

Similar steel grades:

U.S.A | ASTM P20 |

German | 1.2311 |

Japan | PDS-3 |

Austria | - |

Sweden | 618 |

China | P20 |

Chemical composition:

Standard | C | Si | Mn | S | Cr | Ni | Mo |

DIN EN ISO 4957-2018 | 0.37~0.42 | ≤0.40 | 1.40~1.60 | ≤0.005 | 1.80~2.10 | 0.40 | 0.15~0.25 |

Principal Feature:

German mold steel 1.2311. This steel is produced through an "ultra-pure" process and is pre-hardened. 1.2311 steel shows a high degree of micro-purity and excellent homogeneous structure, excellent polishability and photo-etching properties. After heat treatment, DIN 1.2311 tool steel has good processing and polishing properties, can be nitrided, and is suitable for surface treatments such as chrome plating. The material has uniform hardness (up to 400mm thick), good toughness, and good machining performance.

Typical Application:

DIN 1.2311 tool steel Used for large-scale long-life plastic injection molds, such as home appliances, computer casings and other molds. Plastic product mold blow molds with high surface finish can be used as slider forming tools in plastic molds due to their high hardness; mold parts that can be flame hardened or nitrided depending on production needs. ① Used for zinc, aluminum, magnesium and their alloy die-casting molds ② Hot pressing dies, various hot forging dies ③ Metal extrusion die frame.

Heat Treatment:

The initial forging temperature is 1050℃, the final forging temperature is 850℃, and the furnace is slowly cooled.

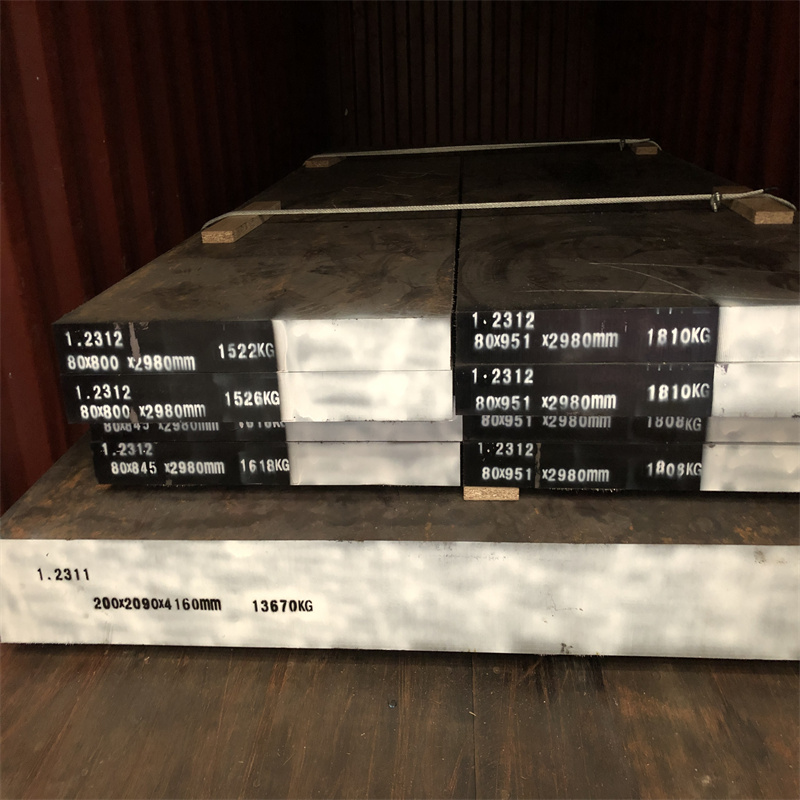

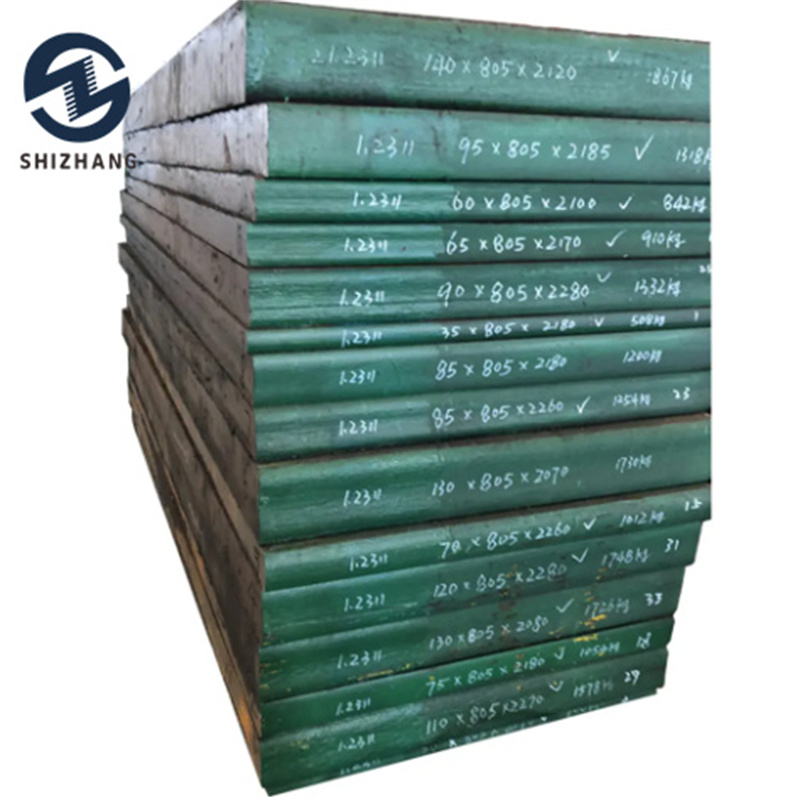

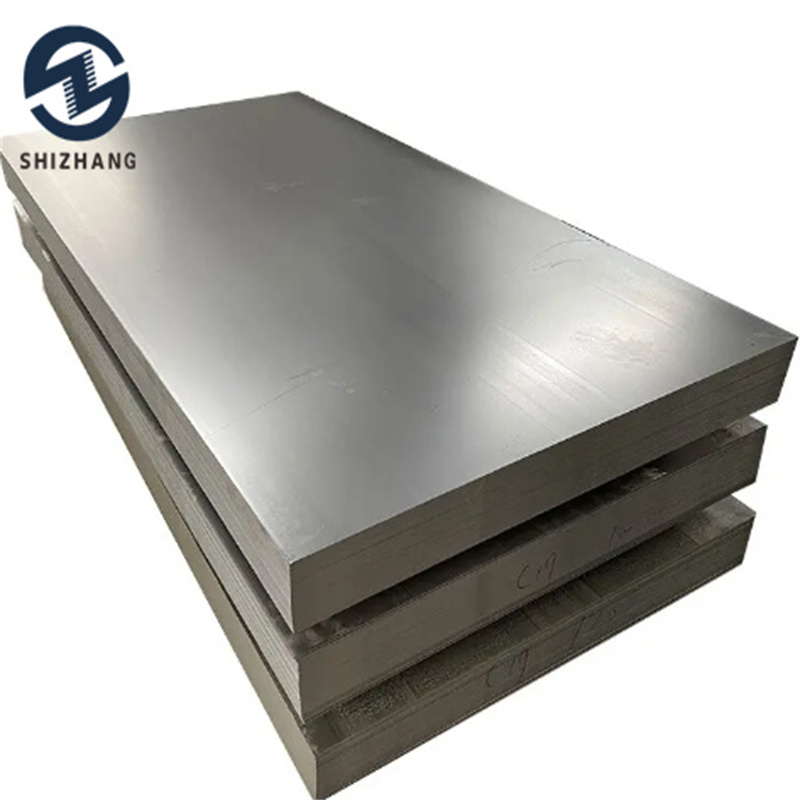

Size available:

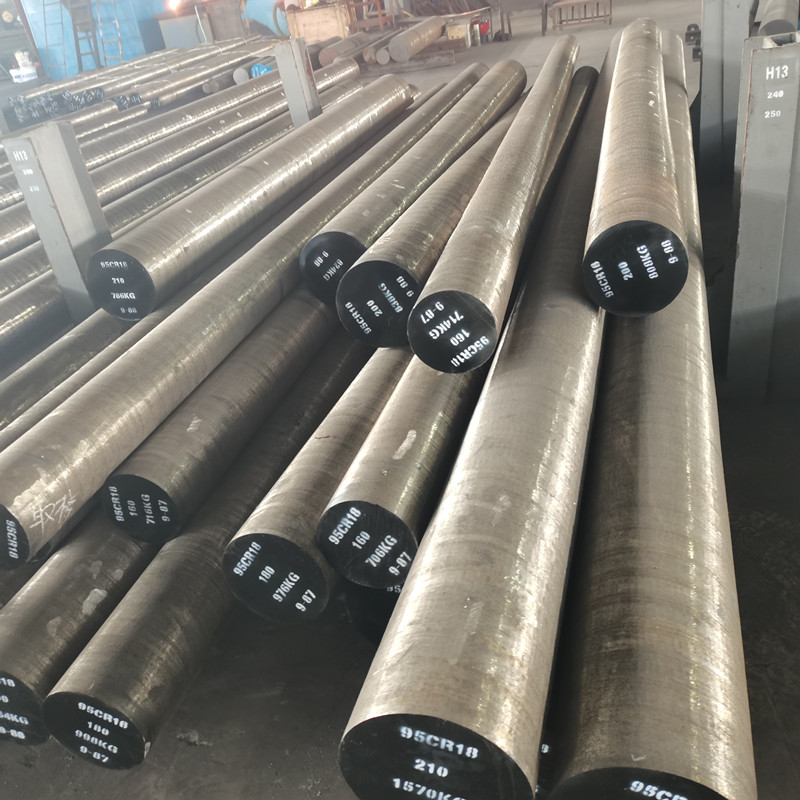

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |