L6 tool steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

L6 tool steel American non-deformable wear-resistant steel is alloy structural steel, heat-resistant and wear-resistant forged steel, with good impact resistance, appropriate hardness and good toughness。Our company are tool steel suppliers

Product Name: ALLOY STEEL---L6

Similar steel grades:

U.S.A | ASTM L6 |

German | DIN 1.2714 |

Japan | JIS SKT4 |

Austria | - |

Sweden | - |

China | 5CrNiMo |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | Ni | Mo |

ASTM A681 | 0.65--0.75 | 0.1-0.5 | 0.25-0.8 | ≤0.030 | ≤0.030 | 0.6-1.2 | 1.25-2 | ≤0.5 |

Principal Feature:

L6 tool steel is an American non-deformable wear-resistant steel, alloy structural steel, heat-resistant and wear-resistant forged steel, with good impact resistance, appropriate hardness and good toughness. L6 tool steel are commonly used steel, which has good comprehensive mechanical properties and high hardenability, and can make steel materials with larger cross-sections obtain more uniform hardness. L6 steel has good polishing properties, and the surface roughness value of the mold made of 90% is low. Molds made of this steel are generally quenched and tempered first, with a hardness of 28 to 35HRC (i.e. pre-hardened). The mold can be used directly after cold processing, which not only ensures the performance of the mold, but also avoids mold damage caused by heat treatment. deformation.

Typical Application:

L6 tool steel is used to make various large and medium-sized hot forging dies. L6 steel is suitable for making various medium and large hammer forging dies with complex shapes and heavy impact loads. Large forging dies that require better toughness than 5CrMnMo.

Heat Treatment:

Quenching temperature 830~860℃, oil cooling quenching.

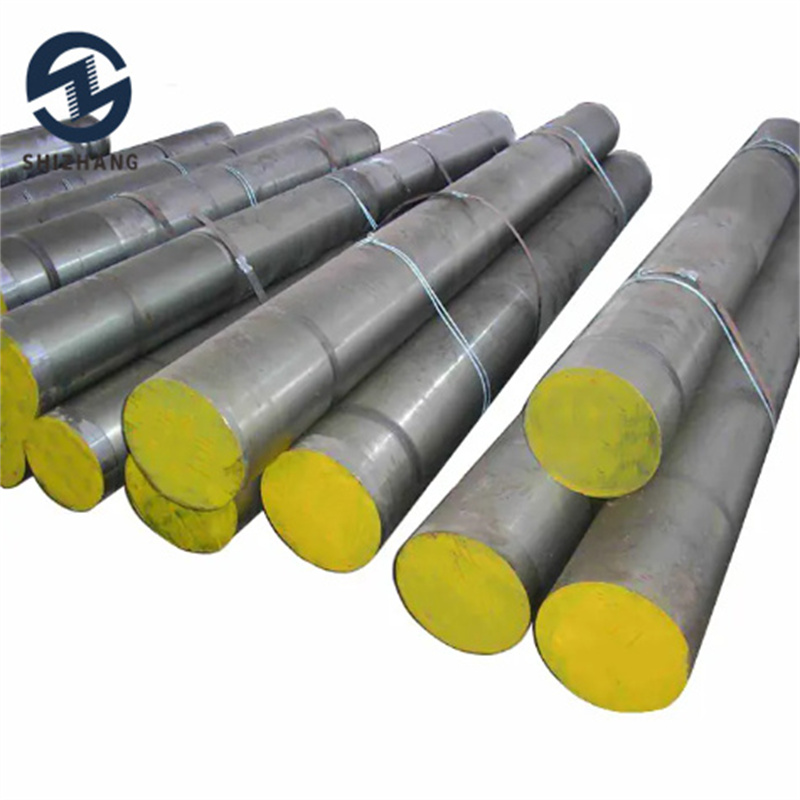

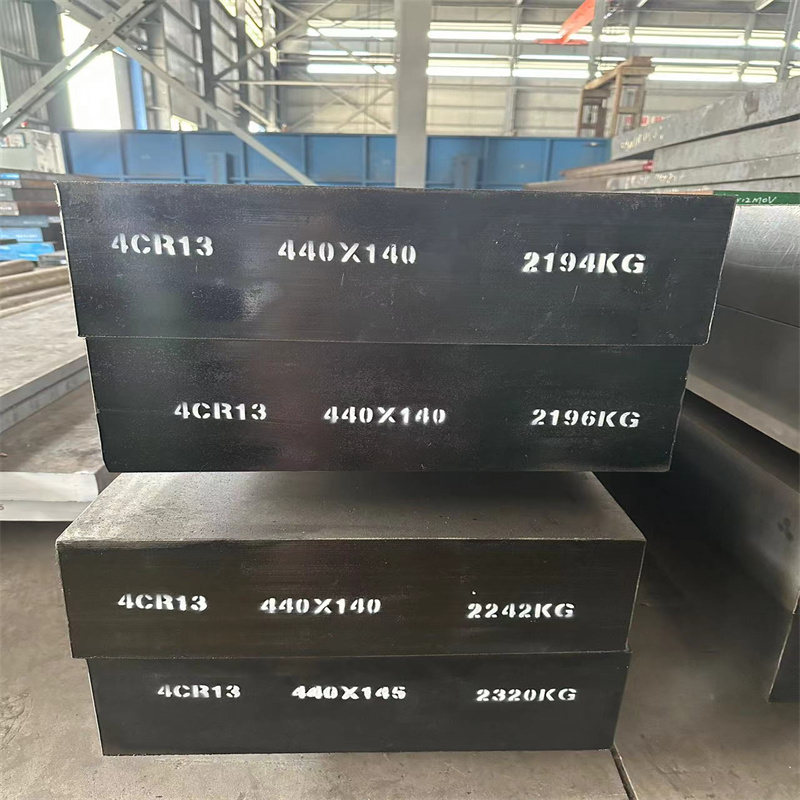

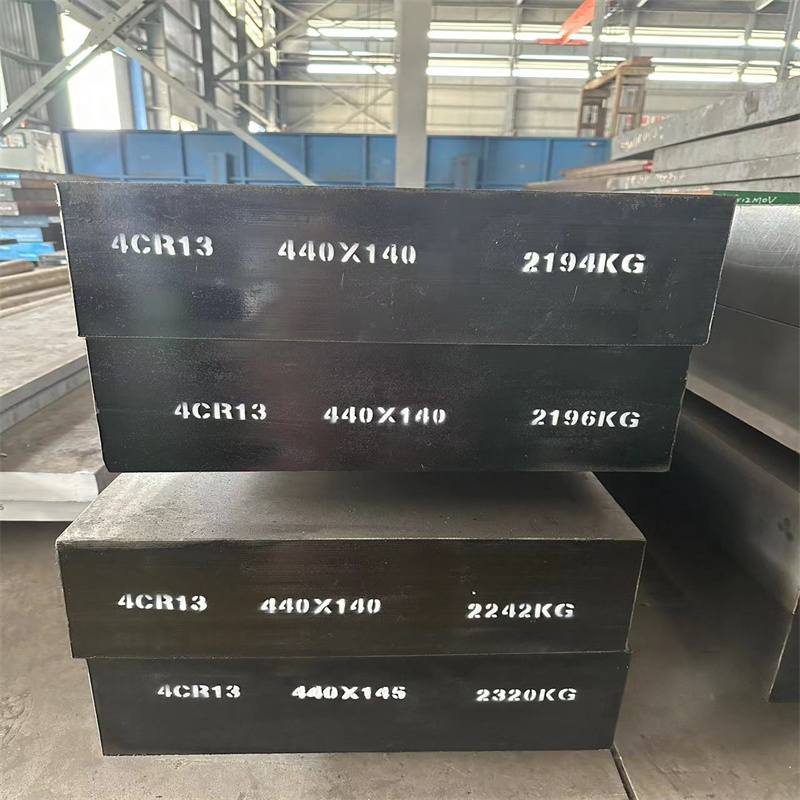

Size available:

Bars | Turned | Dia 90-505mm |

Black | Dia 60-550mm | |

Flats | Milled | T: 70-320 W: 90-1000mm |

Black | T: 50-320 W: 90-1000mm |