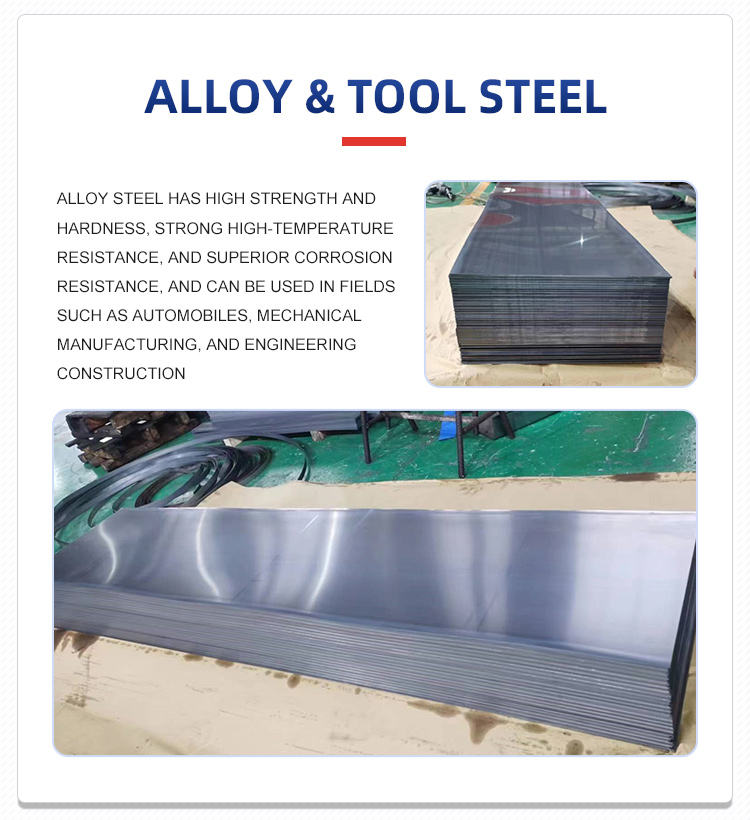

Alloy Steel 9Cr18Mo

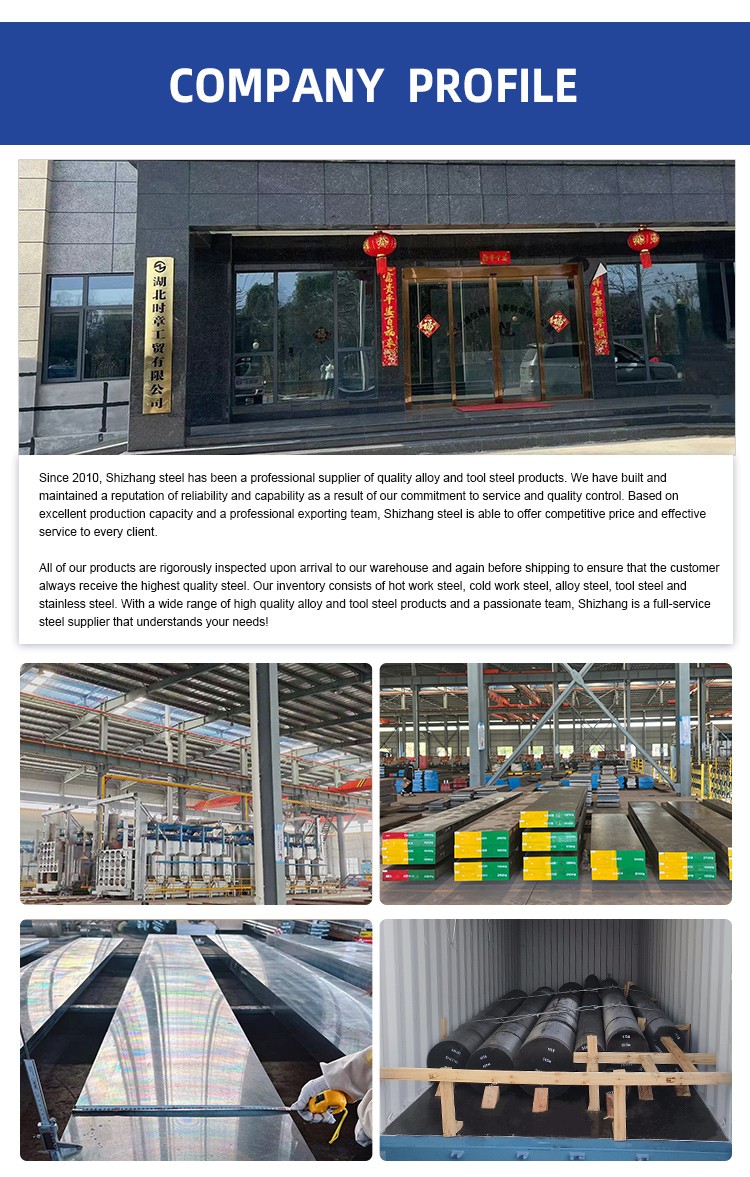

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

9Cr18Mo alloy steel is a high-carbon chromium stainless steel used for making bearing rings and rolling elements. Used as stainless slicing mechanical cutting tools and shearing tools, surgical blades, high wear-resistant equipment parts, etc.The corresponding foreign brand of 9Cr18Mo is ASTM S44004、DIN 1.4125、SUS 440C、102Cr17Mo

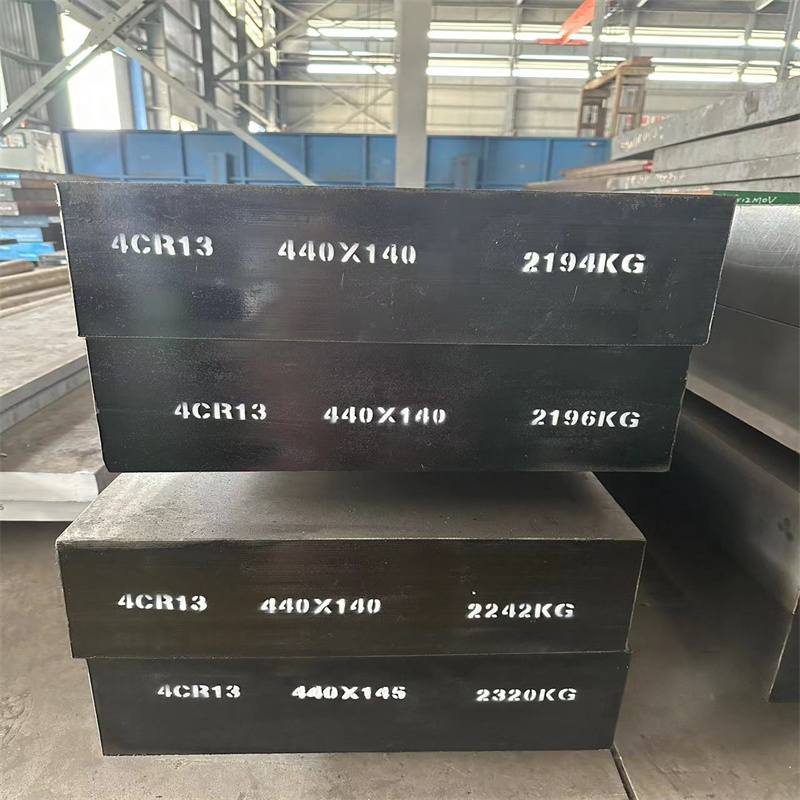

Product Name: ALLOY STEEL---9Cr18Mo

Similar steel grades:

U.S.A | ASTM S44004 |

German | DIN 1.4125 |

Japan | SUS 440C |

Austria | - |

Sweden | - |

China | 9Cr18Mo(102Cr17Mo) |

Chemical composition:

Standard | C | Si | Mo | Cr | P | S | Ni |

GB/T 1220-1992 | 0.9-1.00 | ≤0.8 | ≤0.75 | 16..00-18.00 | ≤0.035 | ≤0.03 | ≤0.6 |

Principal Feature:

9Cr18Mo alloy steel is a high-carbon chromium stainless steel used for making bearing rings and rolling elements.

Typical Application:

9Cr18Mo alloy steel is mainly used to manufacture parts that withstand friction and work in corrosive media, such as bearings, measuring tools and cutting tools. These parts need to have high strength, wear resistance and corrosion resistance to meet the requirements of complex working conditions.

Heat Treatment:

Annealing : slow cooling at 800~920℃ ;

Quenching : 1000~1050℃ oil cooling;

Tempering : oil or air cooling at 200~300℃.

Metallographic structure: The structure is characterized by martensitic structure.

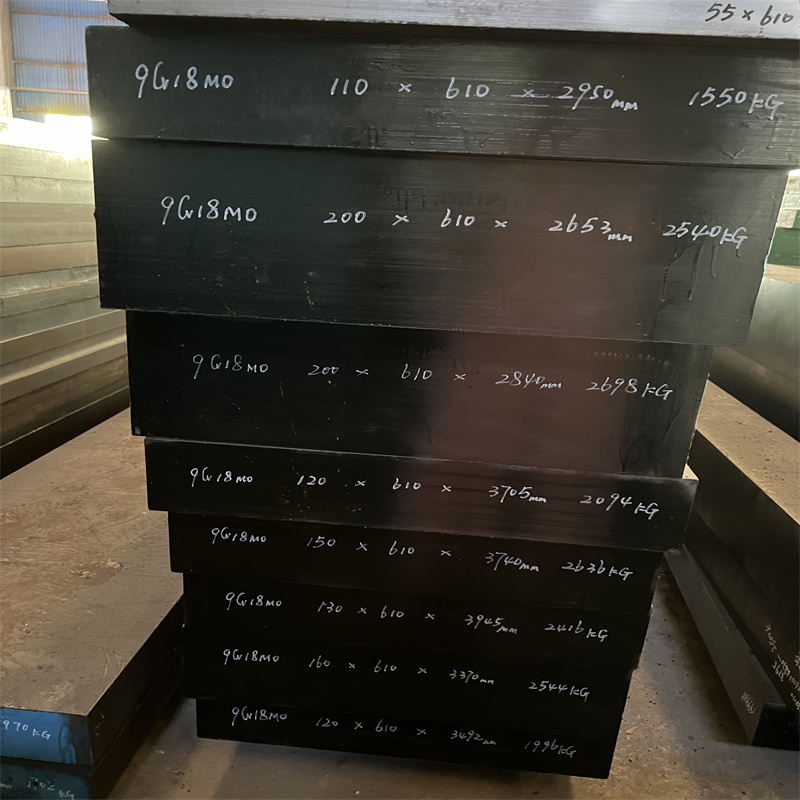

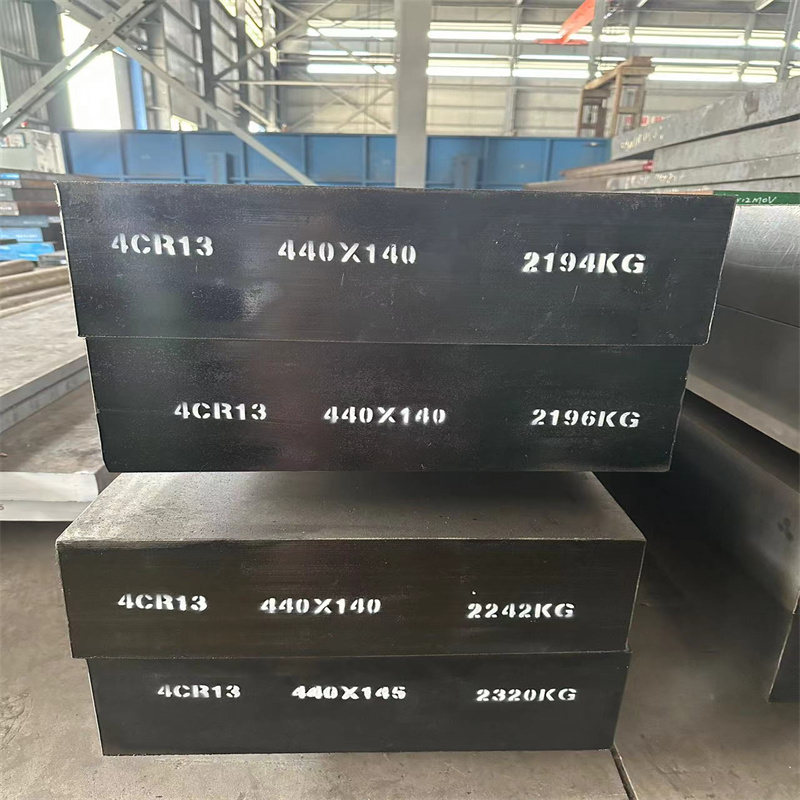

Size available:

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |