NAK80 Pre-Hardened Plastic Die Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

NAK80 steel is Pre-hardened plastic mold steel,No heat treatment, excellent polishing, machinability and etching.

Vacuum degassing and refining to treat steel purity. Low spheroidizing annealing and softening treatment, good machinability. The special addition of strengthening elements vanadium and molybdenum has excellent wear resistance.Our company can provide S2 alloy tool steel round bars and steel plates

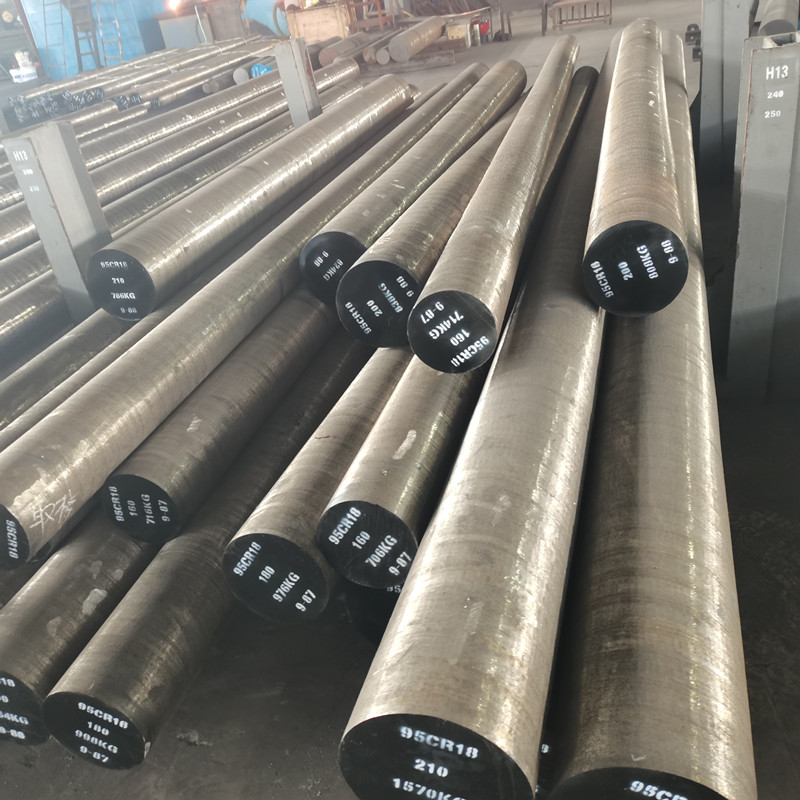

Product Name:Plastic Mould Steel---NAK80

Similar steel grades:

U.S.A | - |

German | - |

Japan | NAK80 |

Austria | - |

Sweden | - |

China | NAK80 |

Chemical composition:

Standard | C | Si | Mn | Al | Cu | Ni | Cr | Mo |

JIS | 0.05-0.25 | 0.1-0.7 | 1.0-2.0 | 1.0 | 1.0 | 2.0-4.0 | 0.3 | 0.2-0.5 |

Principal Feature:

NAK80 steel is Pre-hardened plastic mold steel,No heat treatment, excellent polishing, machinability and etching.

Vacuum degassing and refining to treat steel purity.

Low spheroidizing annealing and softening treatment, good machinability.

The special addition of strengthening elements vanadium and molybdenum has excellent wear resistance.

Typical Application:

JIS NAK80 plastic steel is used in mirror polishing mold, dust prevention, TV filter plate, cosmetic box, Precision wrinkle processing mold, office automation equipment, auto parts EDM mold。

Heat Treatment:

Specification for quenching and tempering: quenching temperature 840~870°C, tempering temperature 200~500°C, hardness 50~55HRC.

Size available:

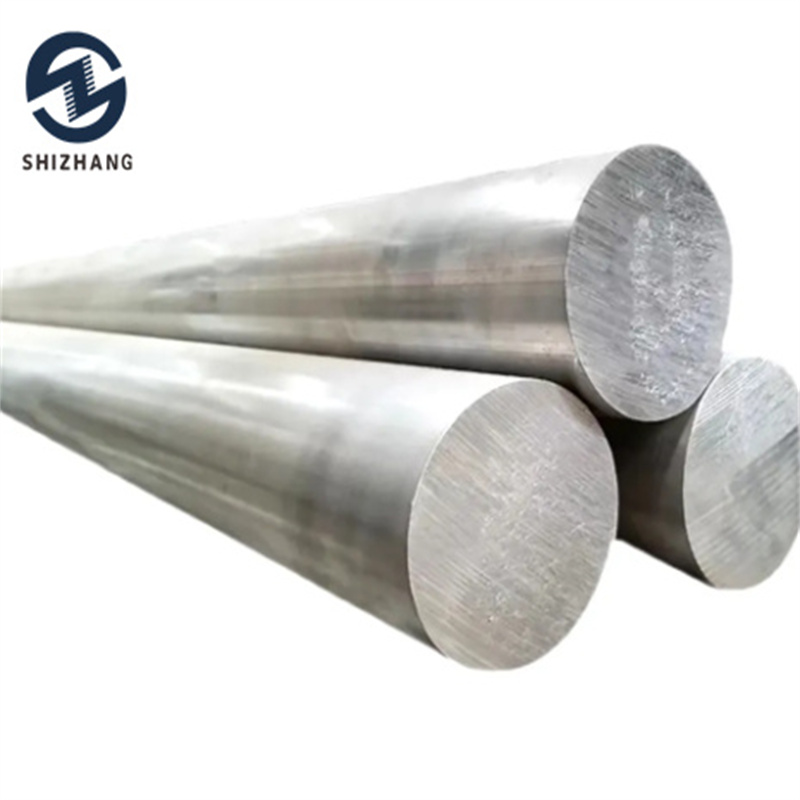

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

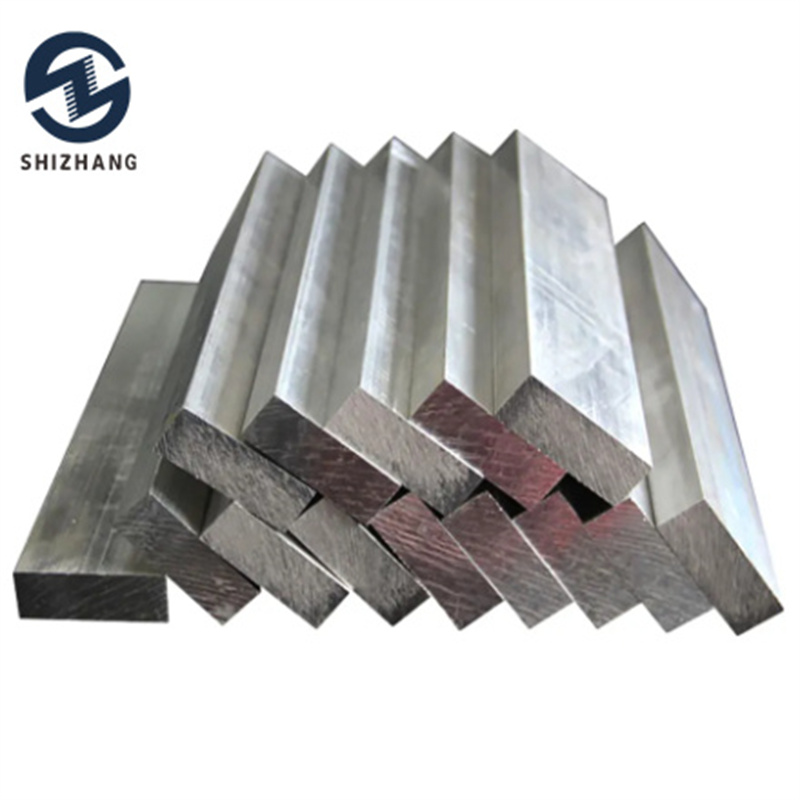

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |