M2 High Speed Steel

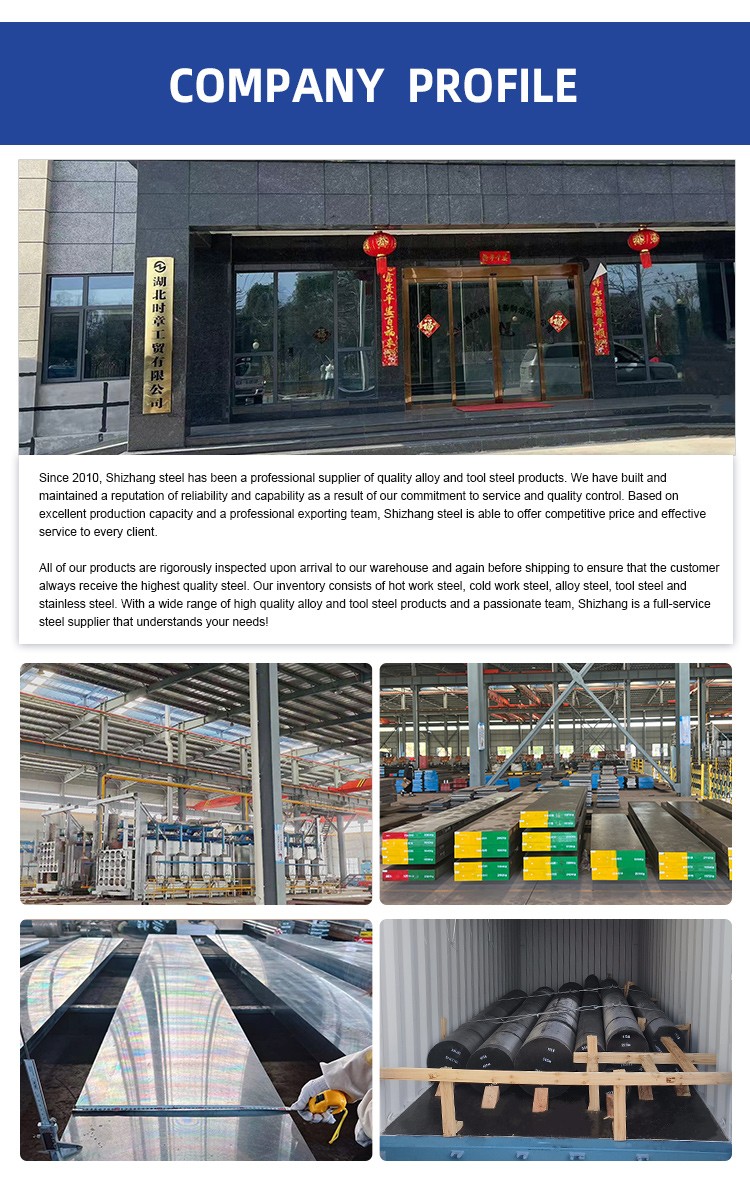

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

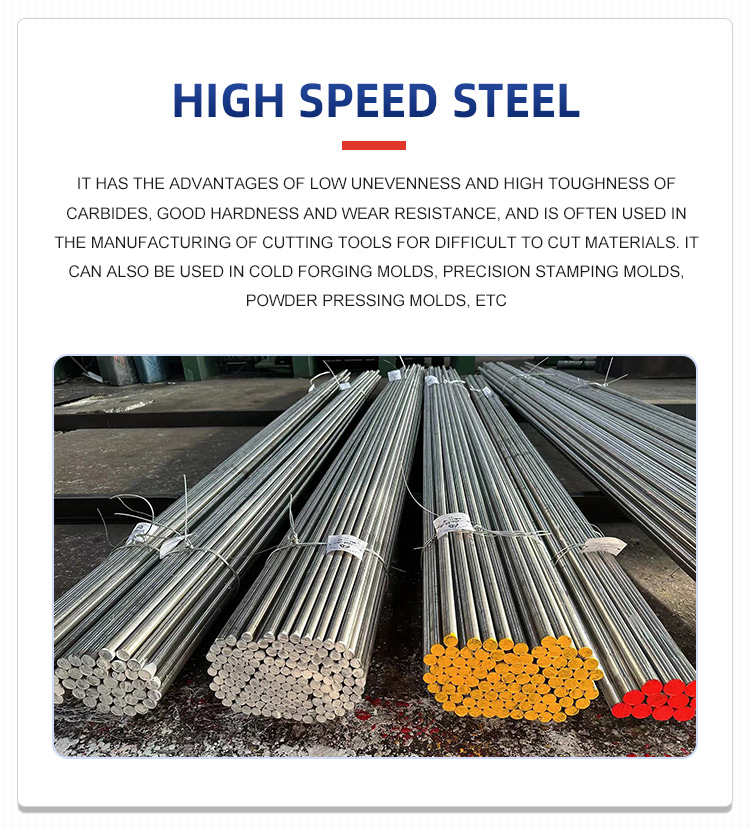

AISI m2 tool steel is molybdenum high speed steel with the advantages of small carbide unevenness and high toughness. AISI m2 steel is easy to overheat, so the quenching heating temperature should be strictly controlled, and the heat treatment protection requirements are strict. Due to hss M2 good hardness and wear resistance, AISI m2 steel is often used to make tools for cutting difficult materials. M2 high speed tool steel has a greater tendency to carbide, so hss M2 has strict requirements for heat treatment protection and is suitable for molds that can withstand vibration and impact loads

Product Name: HIGH SPEED steel---M2

Similar steel grades:

U.S.A | AISI M2 |

German | - |

Japan | - |

Austria | - |

Sweden | - |

China | - |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | Mo | V | W |

ASTM A600-1999 | 0.78-0.88 | 0.2-0.45 | 0.15-0.4 | ≤0.03 | ≤0.03 | 3.75-4.5 | 4.5-5.5 | 1.75-2.2 | 5.5-6.75 |

Principal Feature:

AISI m2 tool steel is molybdenum high speed steel with the advantages of small carbide unevenness and high toughness. AISI m2 steel is easy to overheat, so the quenching heating temperature should be strictly controlled, and the heat treatment protection requirements are strict. Due to its good hardness and wear resistance, M2 steel is often used to make tools for cutting difficult materials. AISI m2 steel has a greater tendency to carbide, so M2 steel has strict requirements for heat treatment protection and is suitable for molds that can withstand vibration and impact loads.

Typical Application:

M2 tool steel can be used in cold forging dies, fine punching dies, powder pressing dies, shearing machine dies, plastic molds with glass fiber added, etc. Molds suitable for withstanding vibration and impact loads: deep drawing dies, punching dies. Metal cutting saw blades, cold heading and extrusion tools, etc.

Heat Treatment:

M2 tool steel high speed tool steel annealing is recommended before Re-hardening. Heating the M2 high speed tool steel to 850°C , The rate of less than 220°C per hour. Keep at temperature for 1 hour per inch(25.4mm) of thickness (with 2 hours being Min). Cool slowly in the heat treatment furnace . The annealed hardness should be 248 HB(Brinell) or lower.

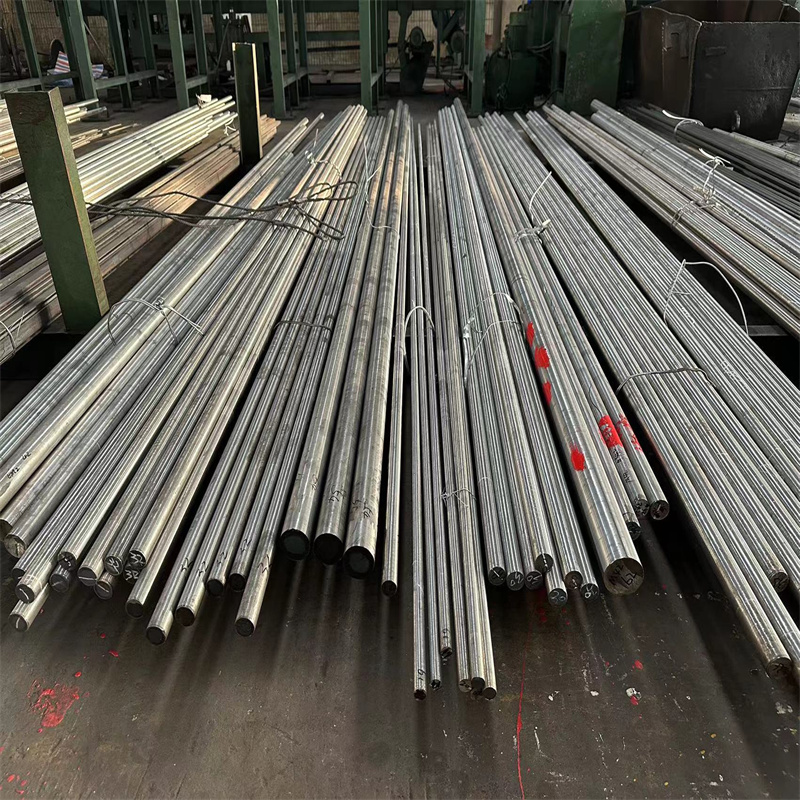

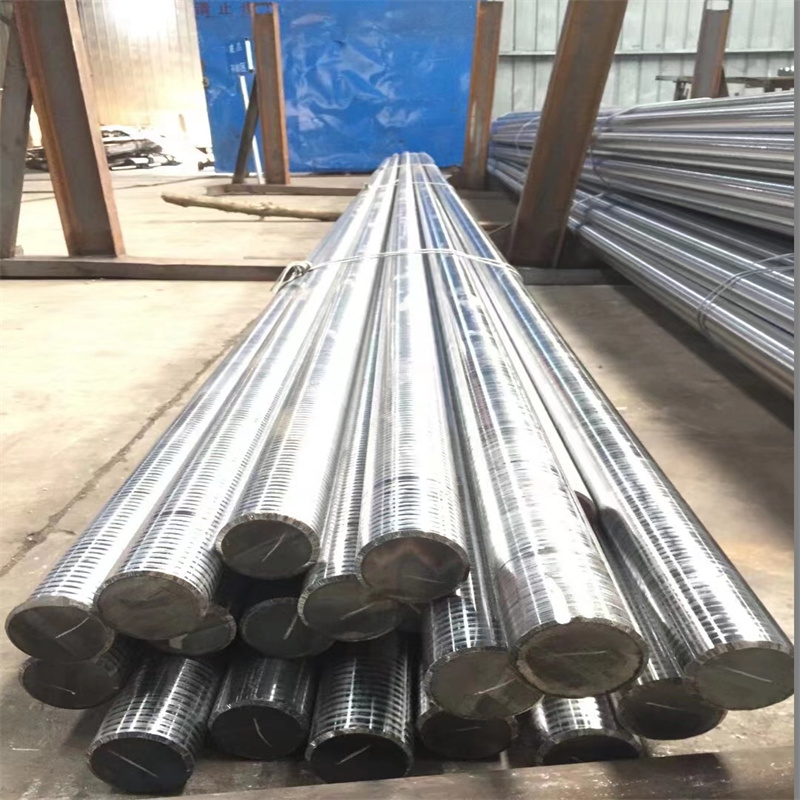

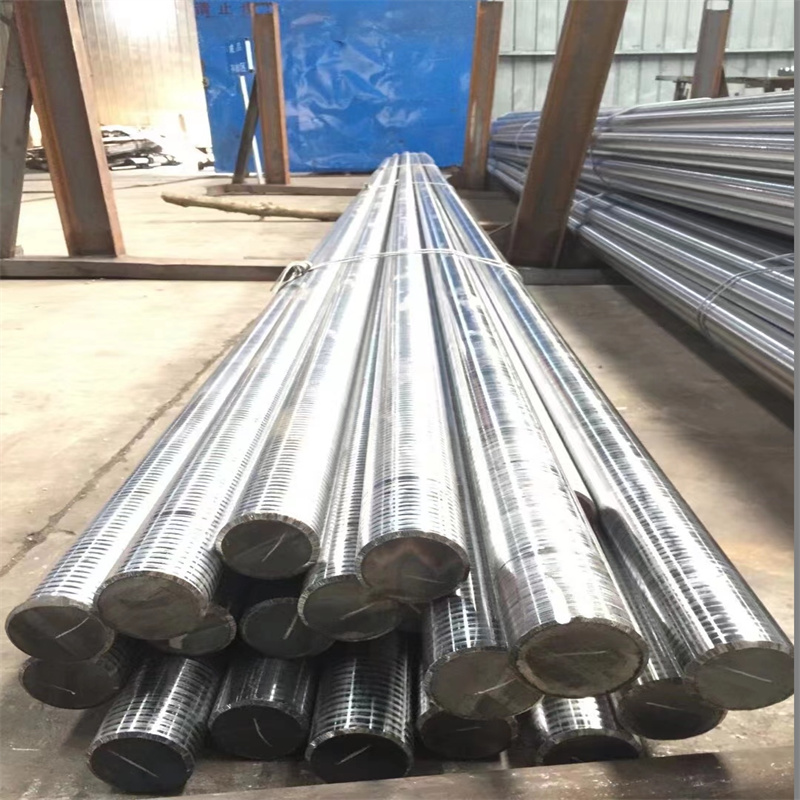

Size available:

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |