M42 High Speed Steel

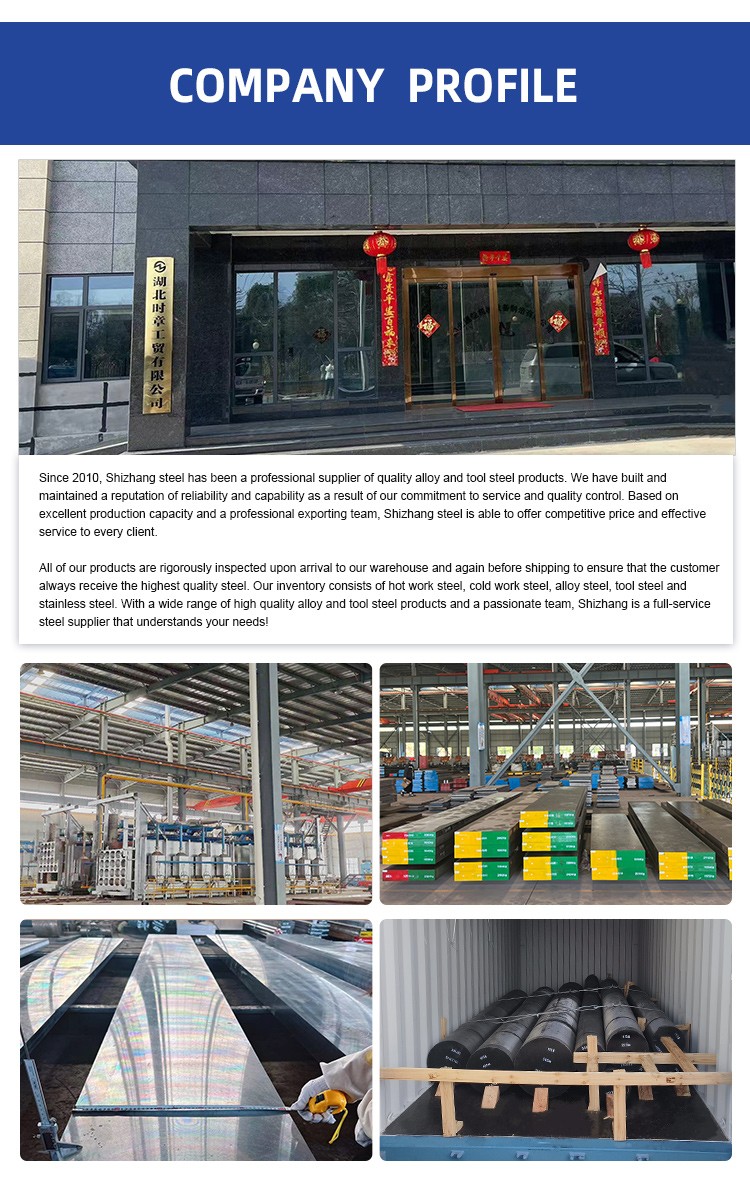

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

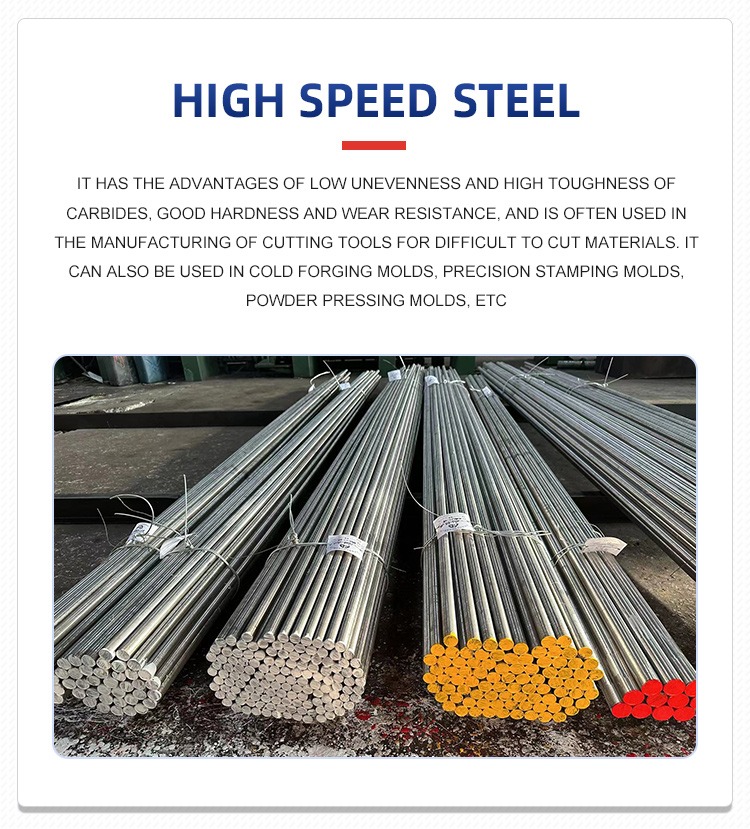

M42 steel is high cobalt toughness high speed steel. M42 tool steel is mainly used for high-toughness precision wear-resistant hardware cold stamping dies. M42 tool steel can also be used for cooling in cutting tools and knives. Steel has high hardness, up to 70HRC, good thermal hardness, high hardness at high temperatures, and easy grinding. Cutting tools made of this steel can cut iron-based high-temperature alloys, cast high-temperature alloys, titanium alloys and ultra-high-strength steels, etc., but the toughness is slightly poorer, and the lower limit should be used for quenching temperatures. Due to its good grindability, M42 tool steel can be used to manufacture various high-precision complex tools.our company are tool steel suppliers

Product Name: High Speed Steel---M42

Similar steel grades:

U.S.A | ASTM M42 |

German | - |

Japan | - |

Austria | - |

Sweden | - |

China | - |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | Mo | V | W |

ASTM A681 | 1.05-1.15 | 0.15-0.65 | 0.15-0.4 | ≤0.03 | ≤0.03 | 3.5-4.25 | 9-10 | 0.95-1.35 | 1.15-1.85 |

Principal Feature:

M42 steel is high cobalt toughness high speed steel. M42 steel is mainly used for high-toughness precision wear-resistant hardware cold stamping dies. M42 steel can also be used for cooling in cutting tools and knives. Steel has high hardness, up to 70HRC, good thermal hardness, high hardness at high temperatures, and easy grinding. Cutting tools made of this steel can cut iron-based high-temperature alloys, cast high-temperature alloys, titanium alloys and ultra-high-strength steels, etc., but the toughness is slightly poorer, and the lower limit should be used for quenching temperatures. Due to its good grindability, M42 steel can be used to manufacture various high-precision complex tools.our company are tool steel suppliers.

Typical Application:

M42 high speed steel can be used in many ways:

Tool industry: scrapers, hobbing cutters, iron knives, drill bits, etc.

Forging industry: forging molds

Screw industry: hexagonal and other heading molds, tapping, punches.

Heat Treatment:

Warm fire: temperature 800~880℃, 10~20℃, dHr furnace cooling to about 600℃, hardness above HB269.

Stress relief: temperature 650~750℃, cooling in furnace.

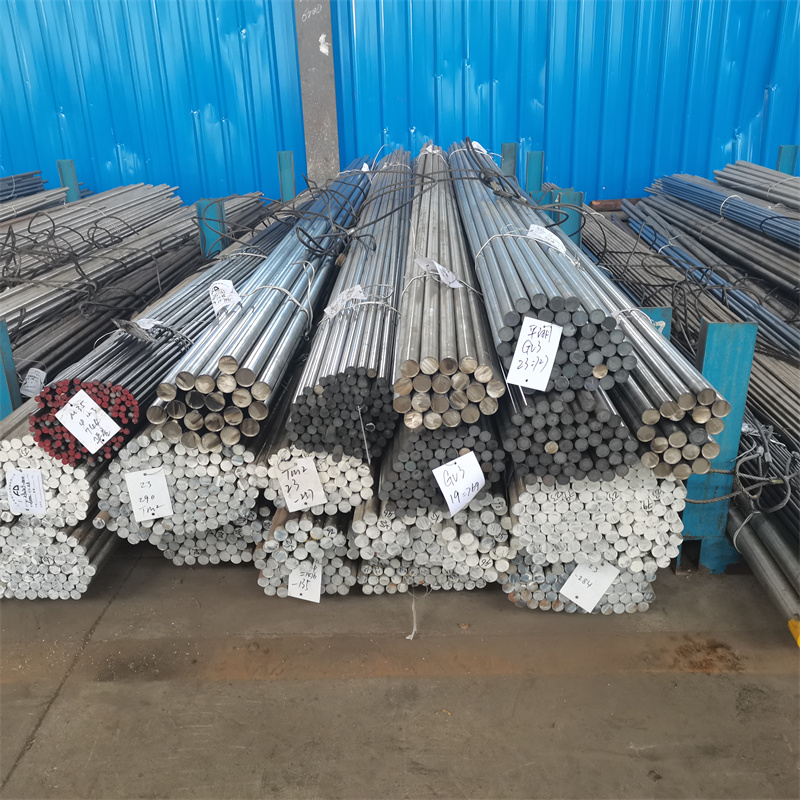

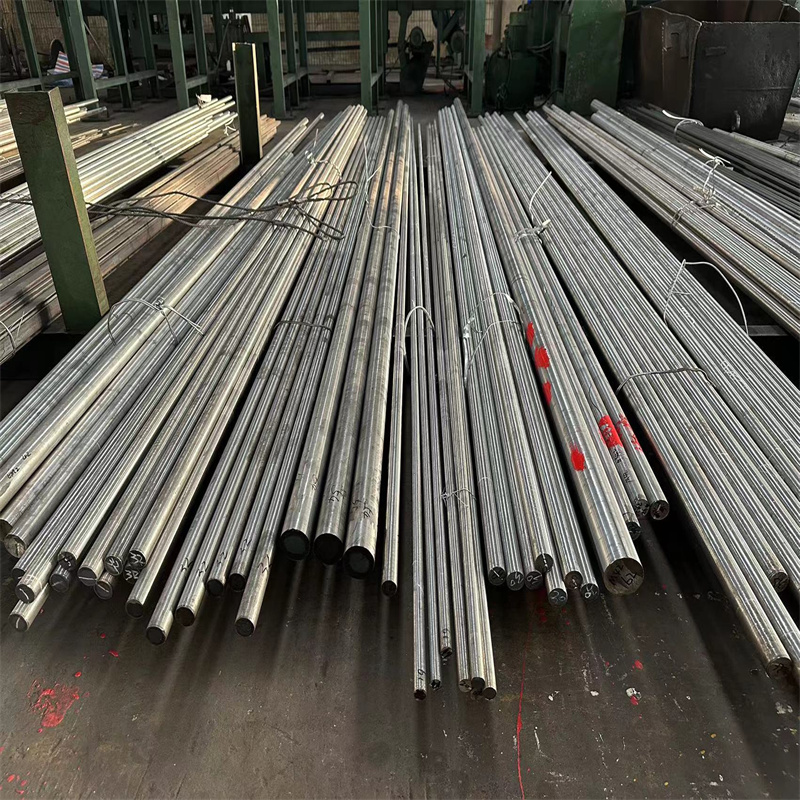

Size available:

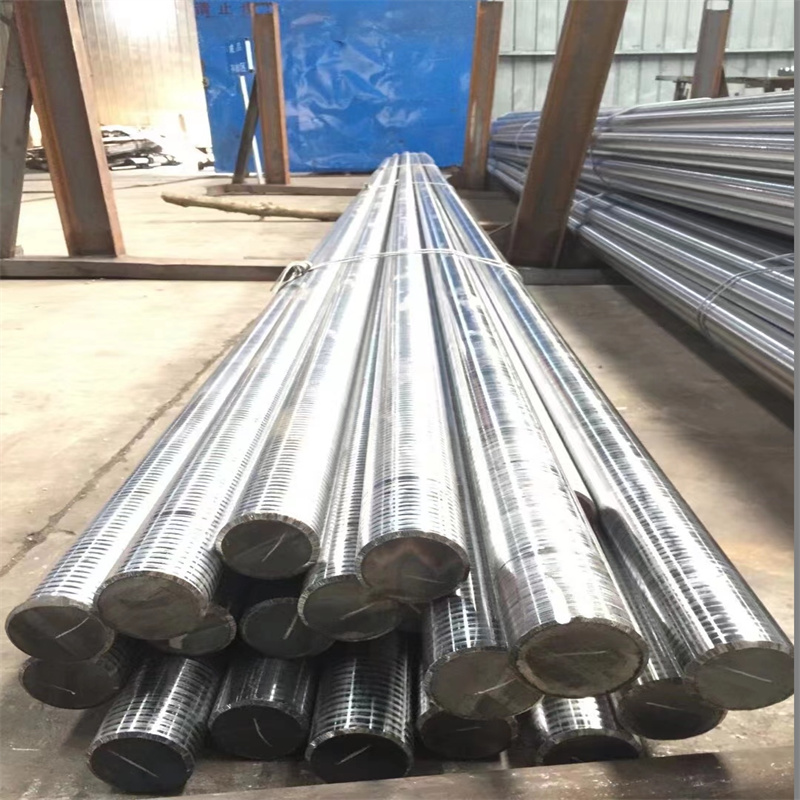

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |