high speed steel

-

Hot

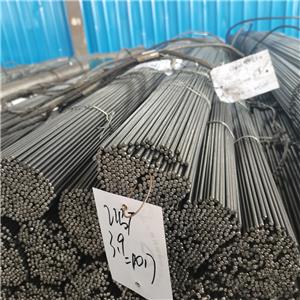

M2 High Speed Steel

AISI m2 tool steel is molybdenum high speed steel with the advantages of small carbide unevenness and high toughness. AISI m2 steel is easy to overheat, so the quenching heating temperature should be strictly controlled, and the heat treatment protection requirements are strict. Due to hss M2 good hardness and wear resistance, AISI m2 steel is often used to make tools for cutting difficult materials. M2 high speed tool steel has a greater tendency to carbide, so hss M2 has strict requirements for heat treatment protection and is suitable for molds that can withstand vibration and impact loads

Email Details -

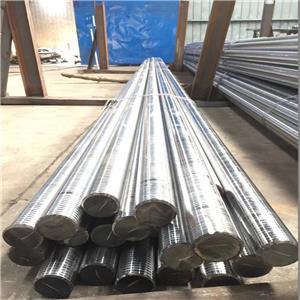

M42 High Speed Steel

M42 steel is high cobalt toughness high speed steel. M42 tool steel is mainly used for high-toughness precision wear-resistant hardware cold stamping dies. M42 tool steel can also be used for cooling in cutting tools and knives. Steel has high hardness, up to 70HRC, good thermal hardness, high hardness at high temperatures, and easy grinding. Cutting tools made of this steel can cut iron-based high-temperature alloys, cast high-temperature alloys, titanium alloys and ultra-high-strength steels, etc., but the toughness is slightly poorer, and the lower limit should be used for quenching temperatures. Due to its good grindability, M42 tool steel can be used to manufacture various high-precision complex tools.our company are tool steel suppliers

Email Details