9SiCr Alloy Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

9SiCr steel has good forging properties. Because it is easy to decarburize, 9SiCr steel needs to be heated in a neutral atmosphere or protective atmosphere furnace. By applying forging heat quenching and tempering treatment, a fine tempered sorbite structure can be obtained, which simplifies the process, saves time and energy, and has both good cutting performance and ideal waste heat treatment structure.The corresponding trademark of 9SiCr steel in other countries is DIN 1.2067、DIN 100Cr6、L3 steel.

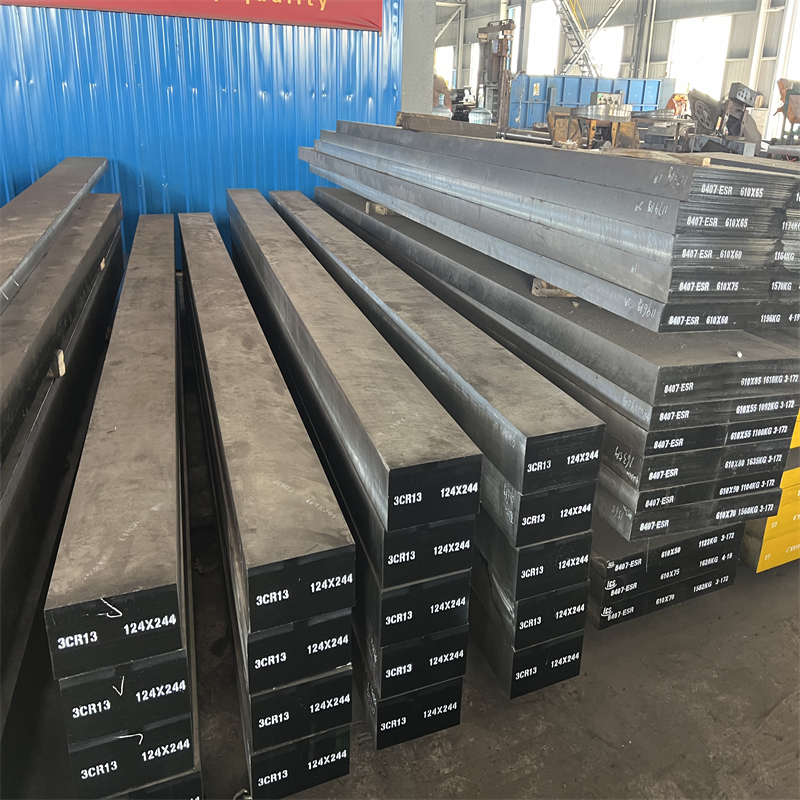

Product Name: ALLOY STEEL---9SiCr

Similar steel grades:

U.S.A | L3 |

German | DIN 1.2067、DIN 100Cr6 |

Japan | - |

Austria | - |

Sweden | 2092 |

China | 9SiCr |

Chemical composition:

Standard | C | Si | Mn | Cr | P | S | Cu | Ni |

GB/T 1299-2000 | 0.85-0.95 | 1.20-1.60 | 0.30-0.60 | 0.95-1.25 | ≤0.03 | ≤0.03 | ≤0.25 | ≤0.30 |

Principal Feature:

9SiCr steel has good forging properties. Because it is easy to decarburize, 9SiCr steel needs to be heated in a neutral atmosphere or protective atmosphere furnace. By applying forging heat quenching and tempering treatment, a fine tempered sorbite structure can be obtained, which simplifies the process, saves time and energy, and has both good cutting performance and ideal waste heat treatment structure.

Typical Application:

9SiCr steel for measuring tools and cutting tools,This steel type is widely used in cold heading dies, cold work dies, various punching and shearing tools, fine embossing tools, high wear resistance, small cutting tools that do not cut violently and deform, gear punching dies, aluminum cold extrusion dies, etc.

Heat Treatment:

One is the conventional spheroidizing annealing process, which heats the workpiece to 800°C to 810°C, holds it for 2 to 4 hours, and then slowly cools it to about 500°C.

The other is the isothermal spheroidizing annealing process. The workpiece is heated to 800°C ~ 810°C, kept for 2 to 4 hours, quickly cooled to 700°C to 720°C, kept for another 4 to 6 hours, and then cooled to about 500°C. , annealed hardness lower than or equal to 229 HBS.

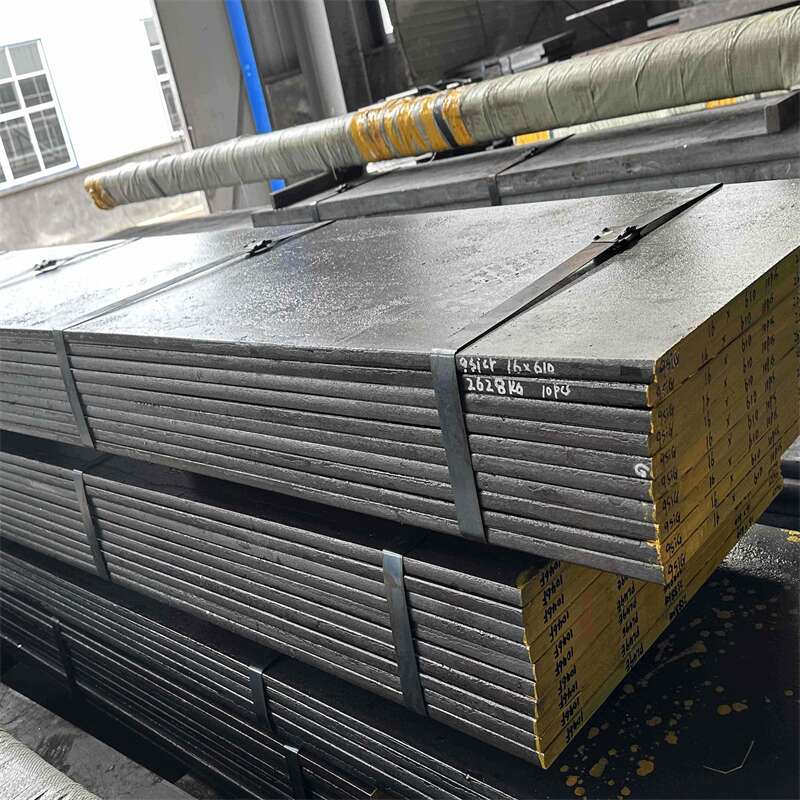

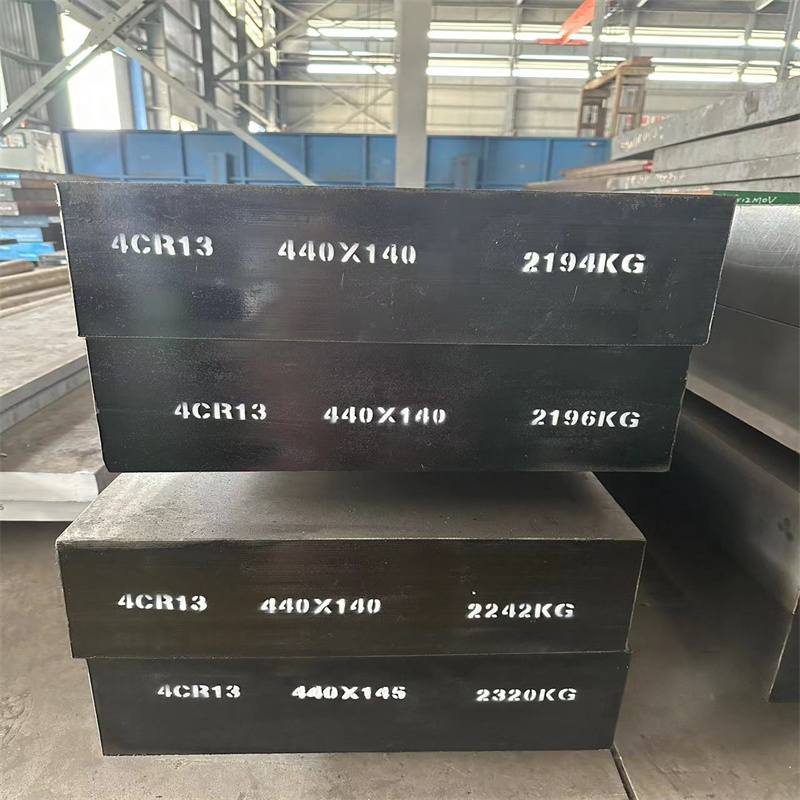

Size available:

Bars | Turned | Dia 1.5-200mm |

Black | Dia 1.5-200mm | |

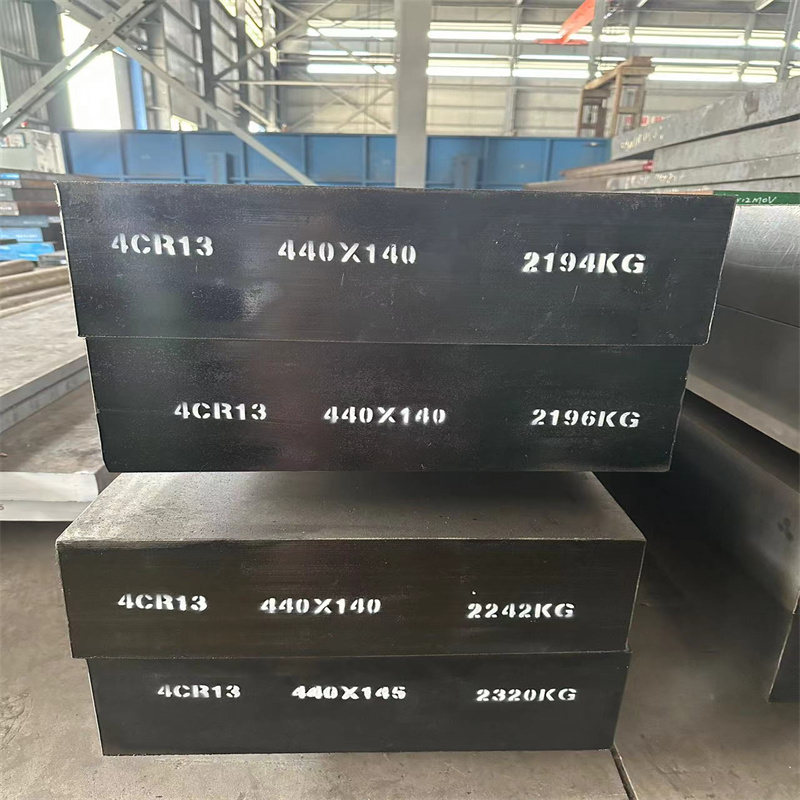

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |