4140 Tool Steel

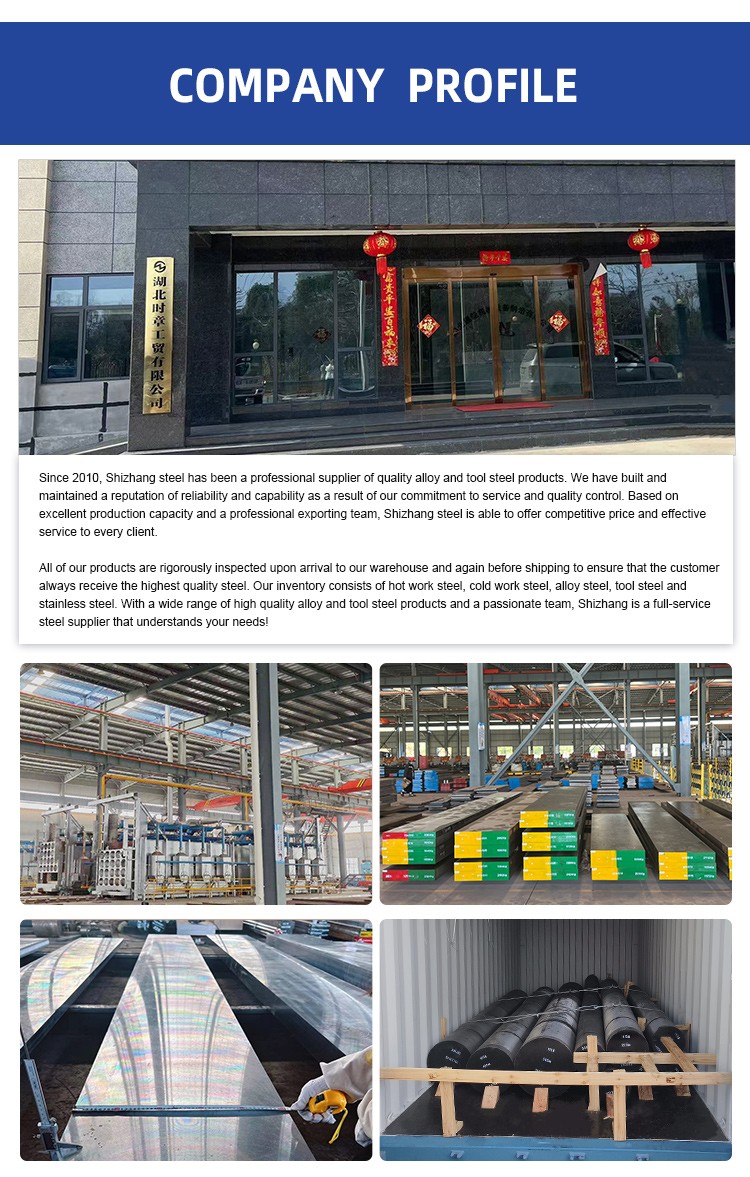

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

4140 tool steel has good processability, minimal processing deformation, and very good fatigue resistance. 4140 tool steel is a medium-hardenability steel. After heat treatment, 4140 steel has good strength and good comprehensive mechanical properties. It has good processability and good yield rate. High. The maximum operating temperature is 427 degrees Celsius. 4140 steel has high strength, hardenability, good toughness, small deformation during quenching, and high creep strength and durable strength at high temperatures

Product Name: Alloy Tool Steel --- 4140

Similar steel grades:

U.S.A | 4140 |

German | 42CrMo4 |

Japan | SCM440 |

Austria | - |

Sweden | - |

China | GB 42CrMo |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | Mo |

ASTM A29/A29M-05 | 0.38-0.43 | 0.15-0.35 | 0.75-1.00 | ≤0.040 | ≤0.035 | 0.80-1.10 | 0.15-0.25 |

Principal Feature:

4140 steel has good processability, minimal processing deformation, and very good fatigue resistance. It is a medium-hardenability steel. After heat treatment, 4140 tool steel has good strength and good comprehensive mechanical properties. 4140 tool steel has good processability and good yield rate. High. The maximum operating temperature is 427 degrees Celsius. 4140 steel has high strength, hardenability, good toughness, small deformation during quenching, and high creep strength and durable strength at high temperatures.

Typical Application:

4140 steel is used to manufacture forgings that require higher strength and larger quenched and tempered cross-sections than 35CrMo steel, such as large gears for locomotive traction, supercharger transmission gears, rear axles, connecting rods and spring clips that are subject to extremely high loads, and also It can be used for deep oil well drill pipe joints and fishing tools below 2000m, and can be used for bending machine molds, etc.

Heat Treatment:

Annealing No.1 "Annealing at 760±10℃, furnace cooling to 400℃ air cooling. HB220-230,

Normalizing No.4 Normalizing at 860±10℃, air cooling after coming out of the furnace.

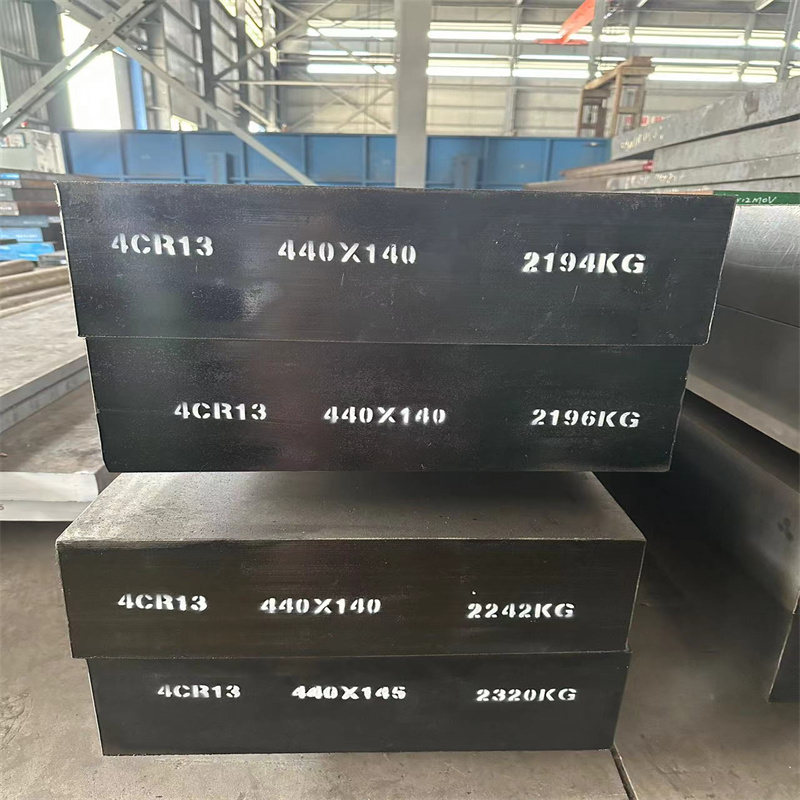

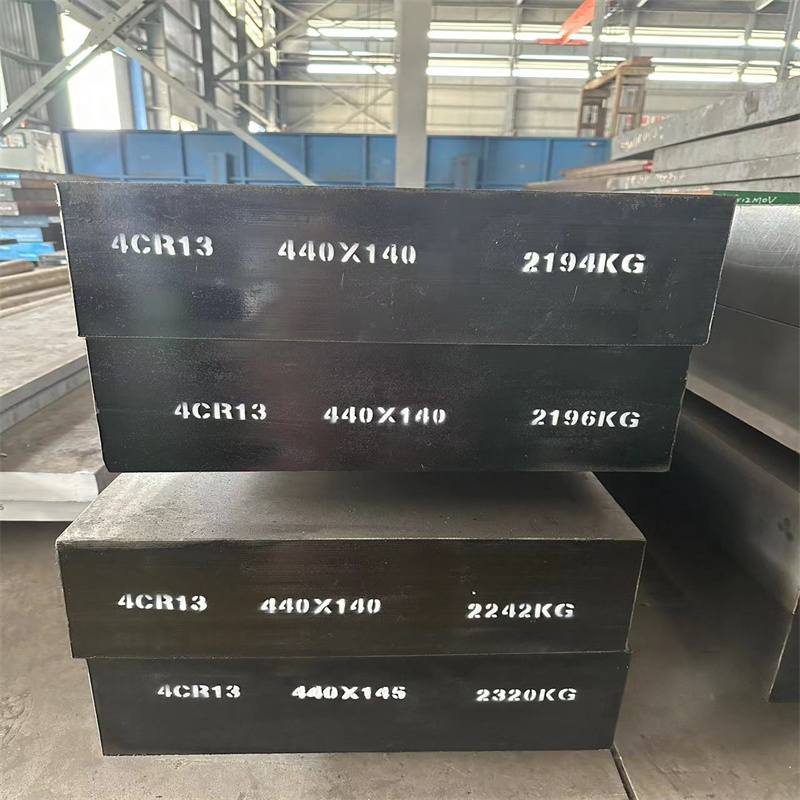

Size available:

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |