20MnCr5 Alloy Structural Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

carburized steel 20MnCr5 is a steel grade imported from Germany, which is equivalent to China's 20CrMn steel. It is carburizing steel and can also be used as quenched and tempered steel. 20MnCr5 steel has good hardenability, small heat treatment deformation, good low-temperature toughness, and good cutting performance, but its weldability is poor. It is generally used after carburizing, quenching, or quenching and tempering.

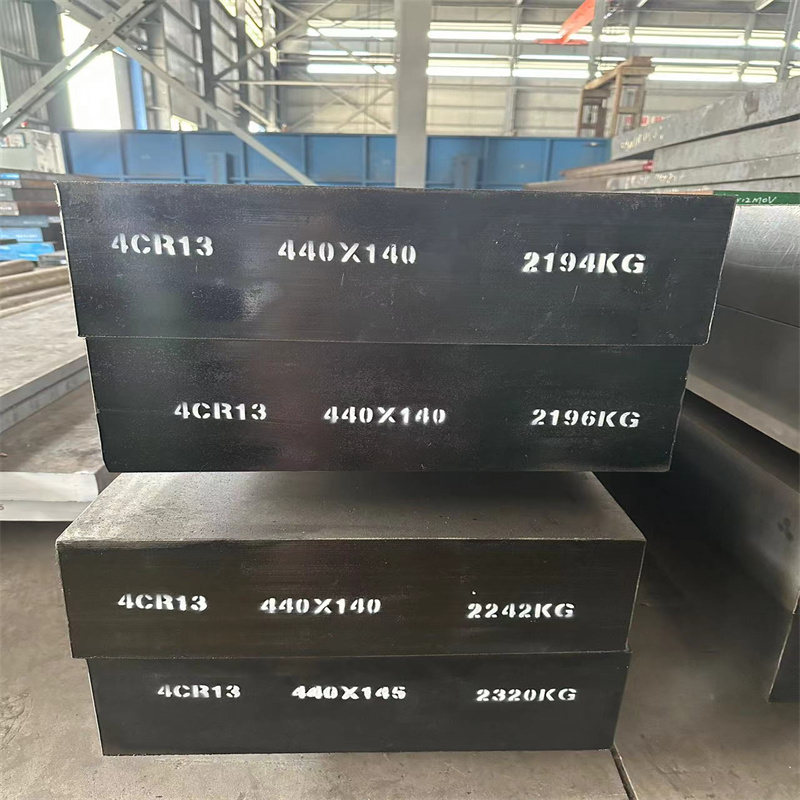

Product Name: ALLOY STEEL---20MnCr5

Similar steel grades:

U.S.A | - |

German | 20MnCr5 |

Japan | - |

Austria | - |

Sweden | - |

China | 20CrMn |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr |

GB/T 7714-2005 | 0.17~0.22 | ≤0.25 | 1.10~1.50 | 0.010~0.035 | ≤0.035 | 1.00~1.30 |

Principal Feature:

carburized steel 20MnCr5 is a steel grade imported from Germany, which is equivalent to China's 20CrMn steel. It is carburizing steel and can also be used as quenched and tempered steel. 20MnCr5 steel has good hardenability, small heat treatment deformation, good low-temperature toughness, and good cutting performance, but its weldability is poor. It is generally used after carburizing, quenching, or quenching and tempering.

Typical Application:

20MnCr5 steel is used to manufacture and heavy-load large-section quenched and tempered parts and small-section carburized parts. It can also be used to manufacture small and medium-sized parts with medium load and small impact, replacing 20CrNi, such as friction in gears, shafts, spindles, and transmission equipment. Wheels, worms, governor sleeves, etc.

Heat Treatment:

Heat treatment specifications: 900℃ oil quenching + 870℃ oil quenching, 200℃ tempering.

Metallographic structure: tempered martensite.

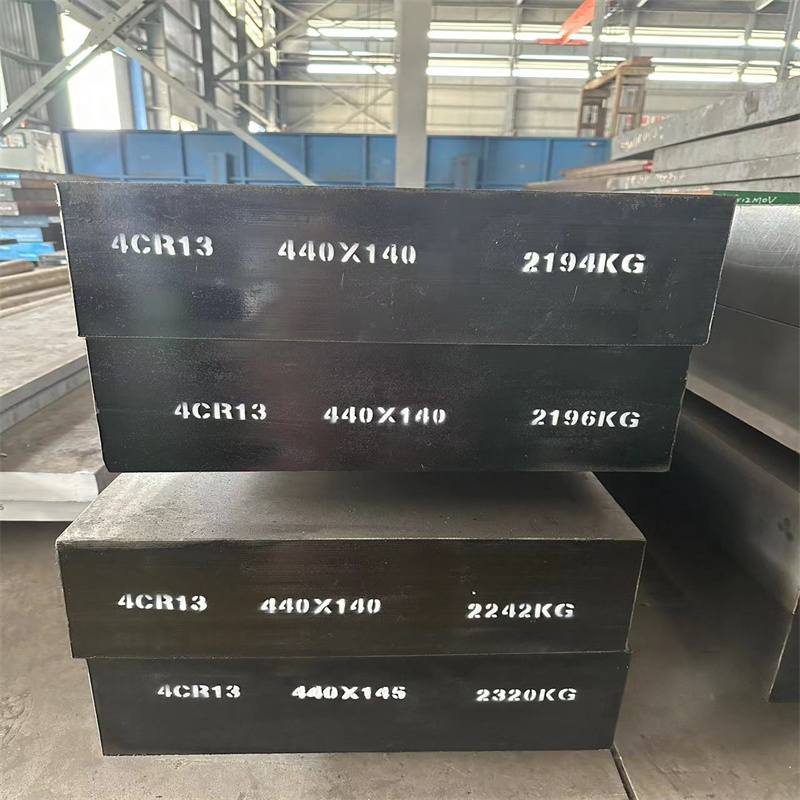

Size available:

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |