skd1

-

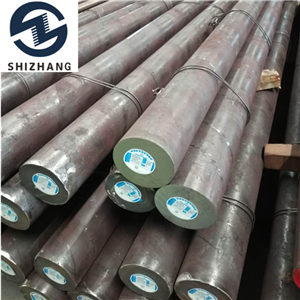

SKD10 Ledeburite Cold Work Die Steel

SKD10 special steel is high carbon, high chromium type ledeburite cold work die steel, cobalt is not a required component unless there are special requirements. SKD10 mold steel has good hardenability, small heat treatment deformation, wear resistance and impact resistance

Email Details -

SKD12 Advanced Cold Work Die Steel

Cold Work Drawn Alloy steel SKD12 has medium alloy content. Because it contains molybdenum and vanadium, it has good hardenability, uniform carbide distribution, certain impact toughness and good wear resistance. It has good air quenching performance, small dimensional deformation during air quenching, better toughness than 9Mn2V and Cr12, uniform and fine carbides, and good wear resistance.SKD12 is air quenching mold steel.

Email Details -

Cold Work Drawn JIS SKD12 Alloy Steel

SKD12 alloy steel has medium alloy content. Because SKD12 steel contains molybdenum and vanadium, SKD12 steel has good hardenability, uniform carbide distribution, certain impact toughness and good wear resistance. SKD12 steel has good air quenching performance, small dimensional deformation during air quenching, better toughness than 9Mn2V and Cr12, uniform and fine carbides, and good wear resistance

Email Details -

AISI D3 Cold Work Steel

AISI D3 steel, American grade, high carbon, high chromium ledeburite steel. AISI D3 steel has high wear resistance, hardenability, hardenability, strength and toughness, thermal stability, compressive strength, micro deformation and excellent It has comprehensive properties, good mechanical processing and thermal oxidation resistance, and wide adaptability.The corresponding trademark of D3 steel in other countries is DIN 1.2080、JIS SKD1、Cr12

Email Details