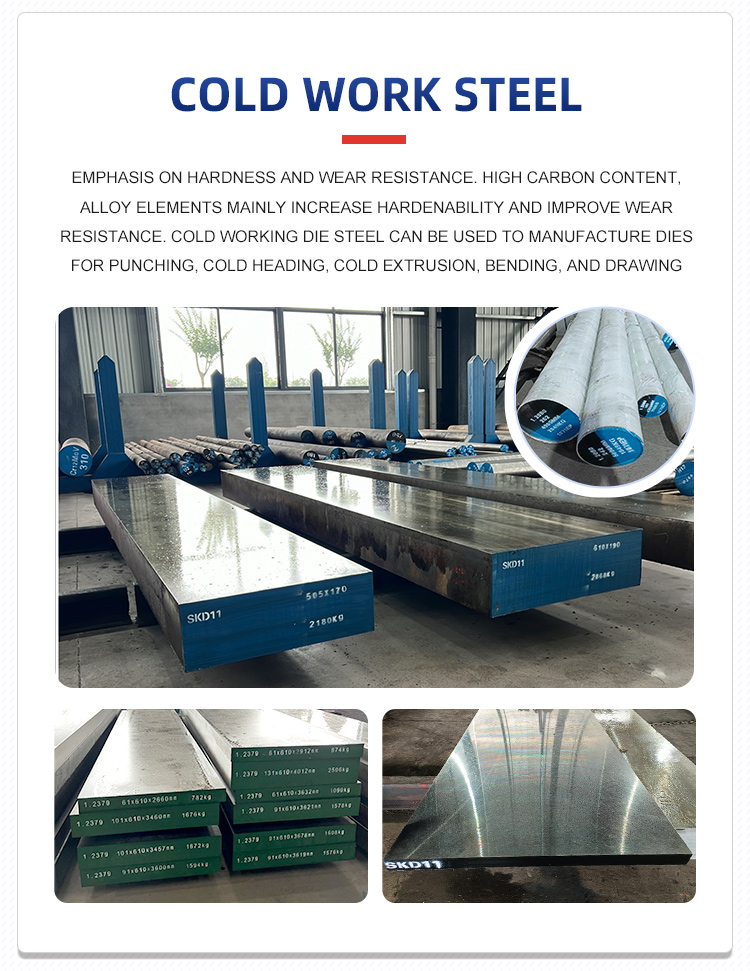

AISI D3 Cold Work Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

AISI D3 steel, American grade, high carbon, high chromium ledeburite steel. AISI D3 steel has high wear resistance, hardenability, hardenability, strength and toughness, thermal stability, compressive strength, micro deformation and excellent It has comprehensive properties, good mechanical processing and thermal oxidation resistance, and wide adaptability.The corresponding trademark of D3 steel in other countries is DIN 1.2080、JIS SKD1、Cr12

Product Name: COLD WORK DIE STEEL---AISI D3

Similar steel grades:

U.S.A | D3 |

German | DIN 1.2080 |

Japan | JIS SKD1 |

Sweden | -- |

China | Cr12 |

Chemical Composition(%) :

C | Si | Mn | Cr | Mo | P | S |

1.90-2.20 | 0.10-0.60 | 0.20-0.60 | 11.0-13.0 | - | 0.03max | 0.02max |

Principal Feature:

AISI D3 Steel is an oil hardening, high carbon/chromium type tool steel.

It has high hardness and wear resistance.

Typical Application:

AISI D3 steel can achieve high hardness and good cutting performance after proper heat treatment, so it is usually used in the manufacture of cutting tools, cold dies and stamping dies.1.2080 steel has excellent wear resistance and can be used under high stress and heavy load conditions.

Heat Treatment:

Forge: Preheat at 900℃-950℃ and then raise to 1050℃-1100℃

Annealing: At 800℃-840℃ Cool slowly in furnace

Stress Relieving: Heat to 650℃, holding for one hour at heat, followed by air cooling

Hardening: Harden from a temperature of 940℃-980℃ followed by oil quenching or warm bath approx. 400℃.

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |