SKD10 Ledeburite Cold Work Die Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

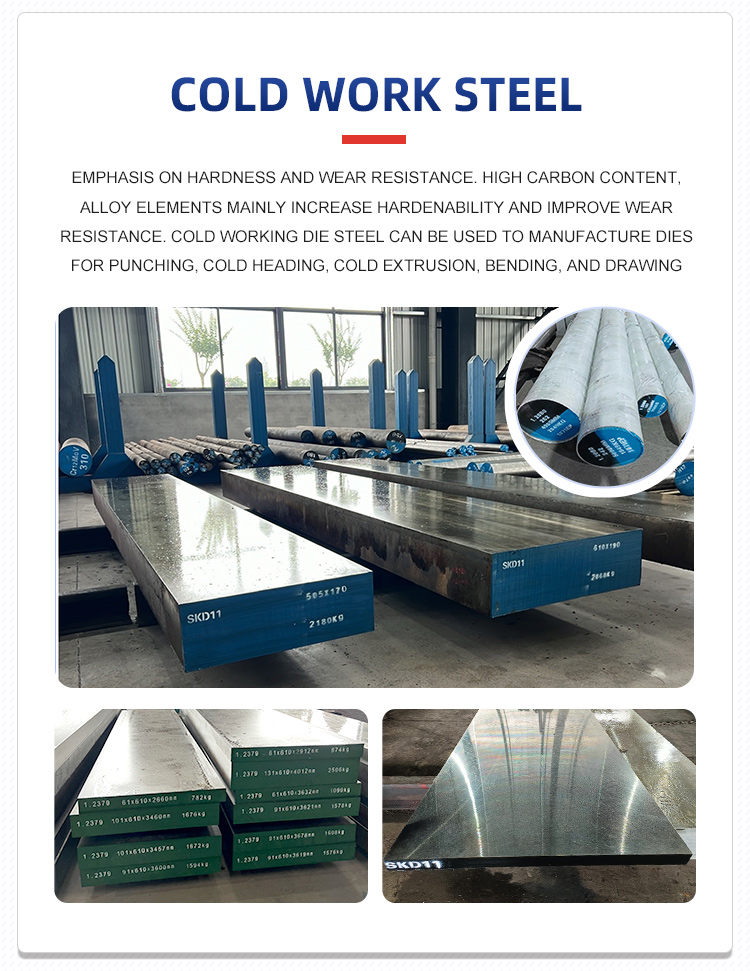

SKD10 special steel is high carbon, high chromium type ledeburite cold work die steel, cobalt is not a required component unless there are special requirements. SKD10 mold steel has good hardenability, small heat treatment deformation, wear resistance and impact resistance

Product Name: COLD WORK DIE STEEL---SKD10

Similar steel grades:

U.S.A | ASTM D5 |

German | DIN 1.2601 |

Japan | JIS SKD10 |

Austria | - |

Sweden | - |

China | Cr12MoV |

Chemical composition:

Standard | C | Si | Mn | Ni | Co | Cr | V | Mo |

JIS G4404 | 1.40-1.60 | ≤0.40 | ≤0.60 | ≤0.25 | ≤1.00 | 11.00-13.00 | 0.20-0.50 | 0.70-1.20 |

Principal Feature:

SKD10 special steel is high carbon, high chromium type ledeburite cold work die steel, cobalt is not a required component unless there are special requirements. SKD10 mold steel has good hardenability, small heat treatment deformation, wear resistance and impact resistance.

Typical Application:

Usage of SKD10 Ledeburite Cold Work Die Steel: mass production of stamping dies, shearing knives, dies, thread rolling dies, porcelain products, etc. It is also used to manufacture large and complex cold work dies that require high wear resistance, such as cold cutting scissors, trimming dies, wire drawing Dies, thread rolling boards, thread rolling dies, rolling dies and cold punching dies and punches that require high wear resistance, etc.

Heat Treatment:

Annealing temperature 830℃-880℃ slow cooling; quenching temperature 1020℃ air cooling; tempering temperature 180℃ air cooling

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |