Steel Surface Difference between Rough Peeled, Turned,Grinding,Polishing and Precisely Drawn

The difference between peeling, turned, grinding, polishing and precisely drawn at the process of steel surface processing is that they are different in their respective treatment methods, purposes and effects.

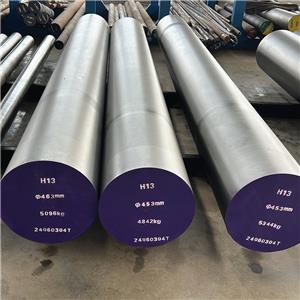

Rough Peeled: Peeling is the first step of steel processing, mainly to remove the oxide skin and impurities on the surface of the steel, to prepare for subsequent processing. This process is usually carried out mechanically or chemically to ensure that the surface of the steel is clean and free of obstructions that would interfere with subsequent processing .

Turned : The lathe is used to process the steel, and the uneven part of the steel surface is removed by cutting, so that it can reach a certain smoothness and dimensional accuracy. The main purpose of turning is to improve the geometric accuracy and dimensional accuracy of steel .

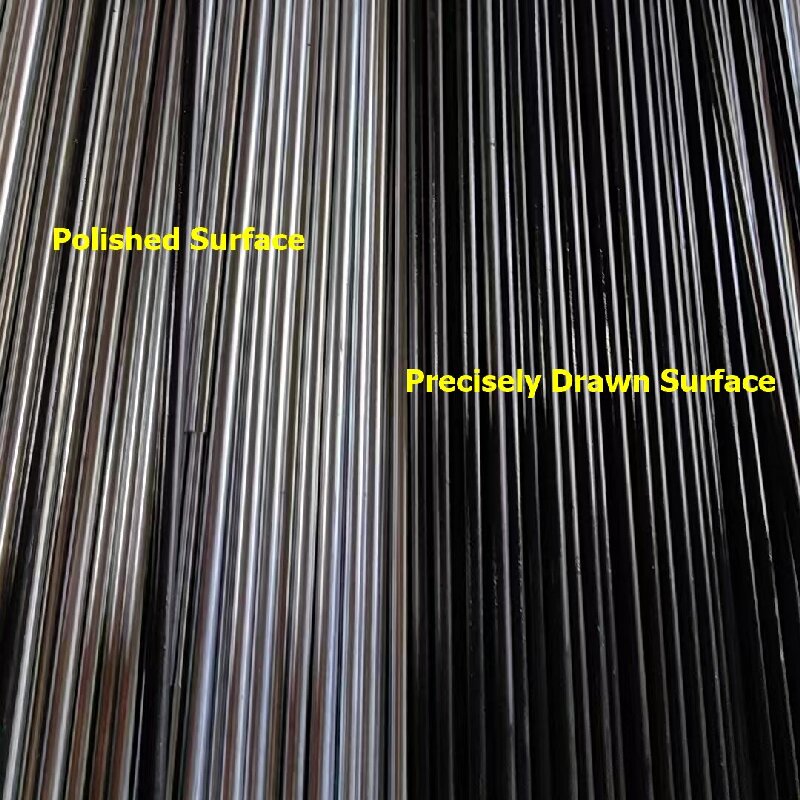

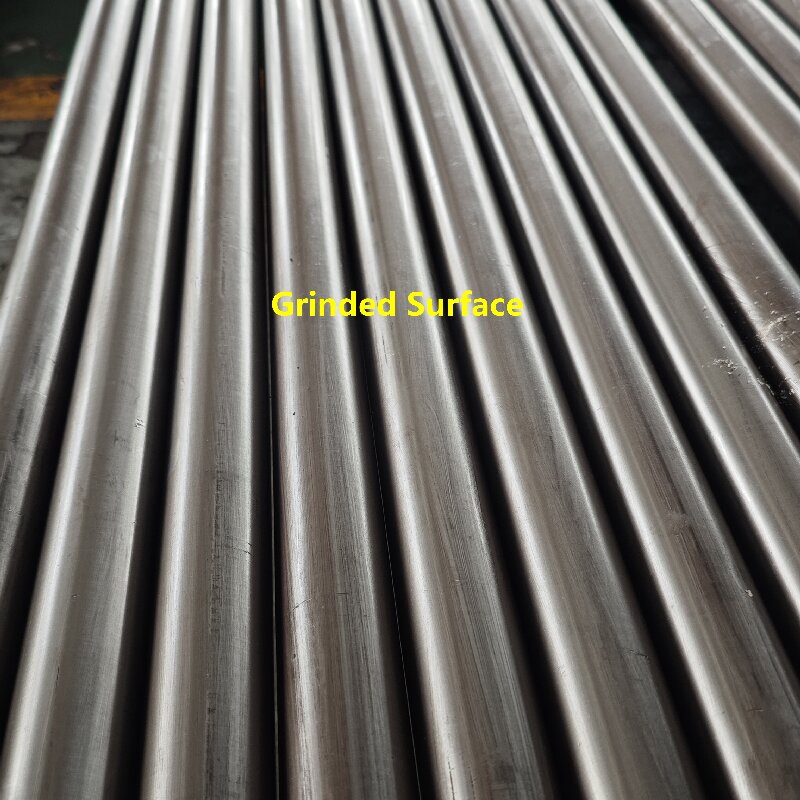

Grinding : Grinding is to process the steel surface by using a certain particle size of abrasive to remove the uneven part of the surface, so that it becomes smooth and flat. Grinding is usually used to treat thicker surface defects or materials with higher roughness. Although there may be slight texture traces on the surface after grinding, it can effectively eliminate surface irregularities and improve the surface quality of steel .

Polishing : Polishing is a more advanced surface treatment method that uses finer abrasives to work the steel surface to achieve a higher surface finish. Polishing can not only remove the uneven part of the surface, but also make the steel surface show a mirror-like luster. Polishing is mainly used to treat very thin surface defects or materials requiring an extremely high gloss .