24 Metal Materials Commonly Used in Mold Processing and Their Characteristics (One)

24 Metal Materials Commonly Used in Mold Processing and Their Characteristics (One)

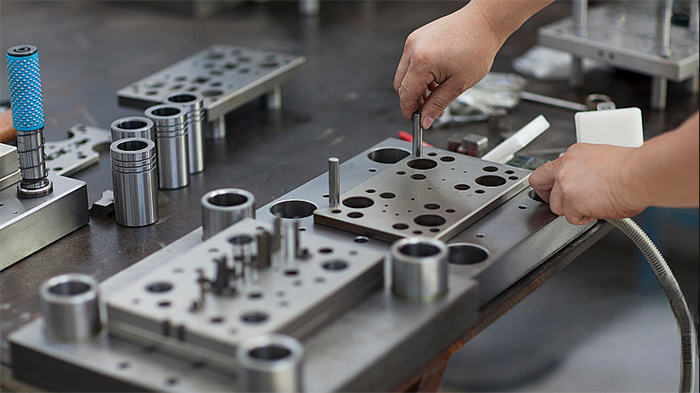

There are more than a hundred materials that can be used for mold processing, such as metals, plastics, inorganic non-metals, paraffin, etc. However, according to different actual needs, the use and demand of each material are different. Today, we will talk about mold processing. The 24 most commonly used metal materials.

1. 45 steel -High quality carbon structural steel, the most commonly used medium-carbon quenched and tempered steel

Main features: The most commonly used medium carbon quenched and tempered steel has good comprehensive mechanical properties, low hardenability, and is prone to cracks during water quenching. Small parts should be quenched and tempered, and large parts should be normalized. Application examples: Mainly used to manufacture high-strength moving parts, such as turbine impellers, compressor pistons, shafts, gears, racks and worms, etc. Pay attention to preheating of welded parts before welding and stress relief annealing after welding.

2. Q235A (A3 steel) - the most commonly used carbon structural steel

Main features: high plasticity, toughness and welding performance, cold stamping performance, certain strength and good cold bending performance. Application examples: Widely used in parts and welded structures with general requirements. Such as tie rods, connecting rods, pins, shafts, screws, nuts, ferrules, brackets, machine bases, building structures and bridges that are not subject to large forces.

3. 40Cr - one of the most widely used steel types, belonging to alloy structural steel

Main features: After quenching and tempering treatment, it has good comprehensive mechanical properties, low temperature impact toughness and low notch sensitivity. It has good hardenability. It can obtain high fatigue strength when oil-cooled. Parts with complex shapes can be easily processed when water-cooled. Cracks occur. The cold bending plasticity is medium, and the machinability is good after tempering or quenching and tempering. However, the weldability is not good and cracks are easy to occur. It should be preheated to 100~150℃ before welding. It is generally used in the quenched and tempered state. It can also be used for carbon-nitrogen processing. Co-infiltration and high-frequency surface quenching treatment. Application examples: After quenching and tempering, it is used to manufacture medium-speed and medium-load parts, such as machine tool gears, shafts, worms, spline shafts and ejector pin sleeves; after quenching and tempering and high-frequency surface quenching, it is used to manufacture high-hardness, durable parts. Grinding parts, such as gears, shafts, spindles, crankshafts, spindles, sleeves, pins, connecting rods, screws and nuts, intake valves, etc.; used to make heavy-duty, medium-speed impact parts after quenching and medium-temperature tempering Parts, such as oil pump rotors, sliders, gears, spindles and collars, etc.; after quenching and low-temperature tempering, used to manufacture heavy-duty, low-impact, wear-resistant parts, such as worms, spindles, shafts and collars, etc.; Carbon After nitriding treatment, transmission parts with larger size and higher low-temperature impact toughness, such as shafts and gears, are manufactured.