24 metal Materials Commonly Used in Mold Processing and Their Characteristics (Four)

24 metal Materials Commonly Used in Mold Processing and Their Characteristics (Four)

14. DC53——high toughness high chromium steel

Produced by Daido Co., Ltd. of Japan. The heat treatment hardness is higher than SKD11. After tempering at high temperature (520~530)℃, it can reach a high hardness of 62~63HRC. DC53 exceeds SKD11 in terms of strength and wear resistance, and its toughness is twice that of SKD11. The toughness of DC53 rarely causes cracks and cracks in cold work mold manufacturing, which greatly improves the service life. The residual stress is small, and the residual stress is reduced after high temperature. Because cracks and deformation after wire cutting are suppressed, the cutting performance and abrasiveness exceed SKD11, and it is used for precision stamping dies, cold forging and deep drawing dies, etc.

15. SKH-9——General-purpose high-speed steel with high wear resistance and toughness

Produced by Hitachi Co., Ltd., Japan. Used for cold forging dies, strip cutting machines, drill bits, reamers and punches, etc.

16. ASP-23——Powder metallurgy high speed steel

Made in Sweden. The carbide distribution is extremely uniform, wear-resistant, high toughness, easy to process, and dimensionally stable after heat treatment. Used for various long-life cutting tools such as punches, deep drawing dies, drilling dies, milling cutters and shear blades.

17. P20——Generally required large and small plastic molds

Made in the United States. Can be operated by electro-erosion. Factory pre-hardened HB270~300, quenching hardness HRC52.

18. 718——High-demand large and small plastic molds

Made in Sweden. Can be operated by electro-erosion. Factory pre-hardened HB290~330, quenching hardness HRC52.

19. Nak80——High mirror surface and high precision plastic mold

Produced by Daido Co., Ltd. of Japan. The factory state is pre-hardened to HB370~400, and the quenching hardness is HRC52.

20. S136 - Anti-corrosion and mirror polished plastic mold

Made in Sweden. Factory pre-hardened HB<215, quenching hardness HRC52.

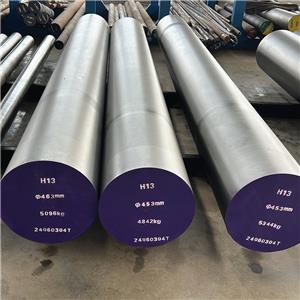

21. H13——Commonly used die-casting mold

Used for aluminum, zinc, magnesium and alloy die-casting, hot stamping dies, aluminum extrusion dies, etc.

22. SKD61——Advanced die-casting mold

Produced by Hitachi Co., Ltd., Japan. Through electric ballast re-dissolution technology, the service life is significantly improved compared to H13. Used for hot stamping dies and aluminum extrusion dies.

23. 8407——Advanced die-casting mold

Made in Sweden. Used for hot stamping dies and aluminum extrusion dies.

24. FDAC - Added sulfur to enhance machinability

The factory pre-hardened hardness is HRC38~42, which can be directly carved without quenching or tempering. Used for small batch molds, simple molds, various resin products, sliding parts, and mold parts with short delivery times. Such as zipper mold, glasses frame mold, etc.