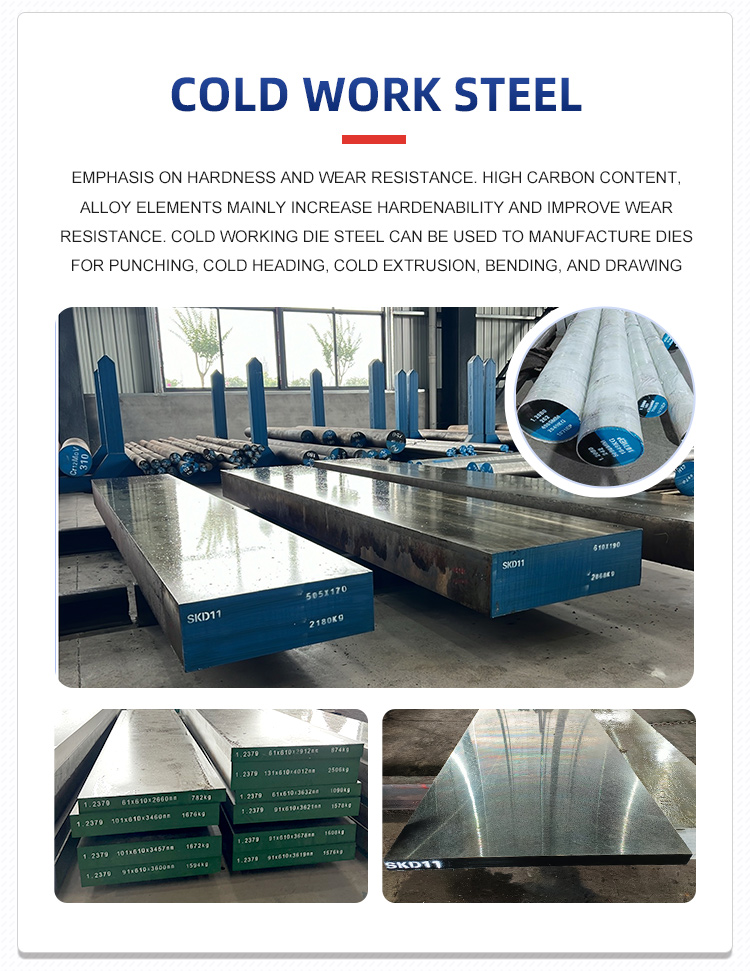

SKS93 Cold Work Die Steel

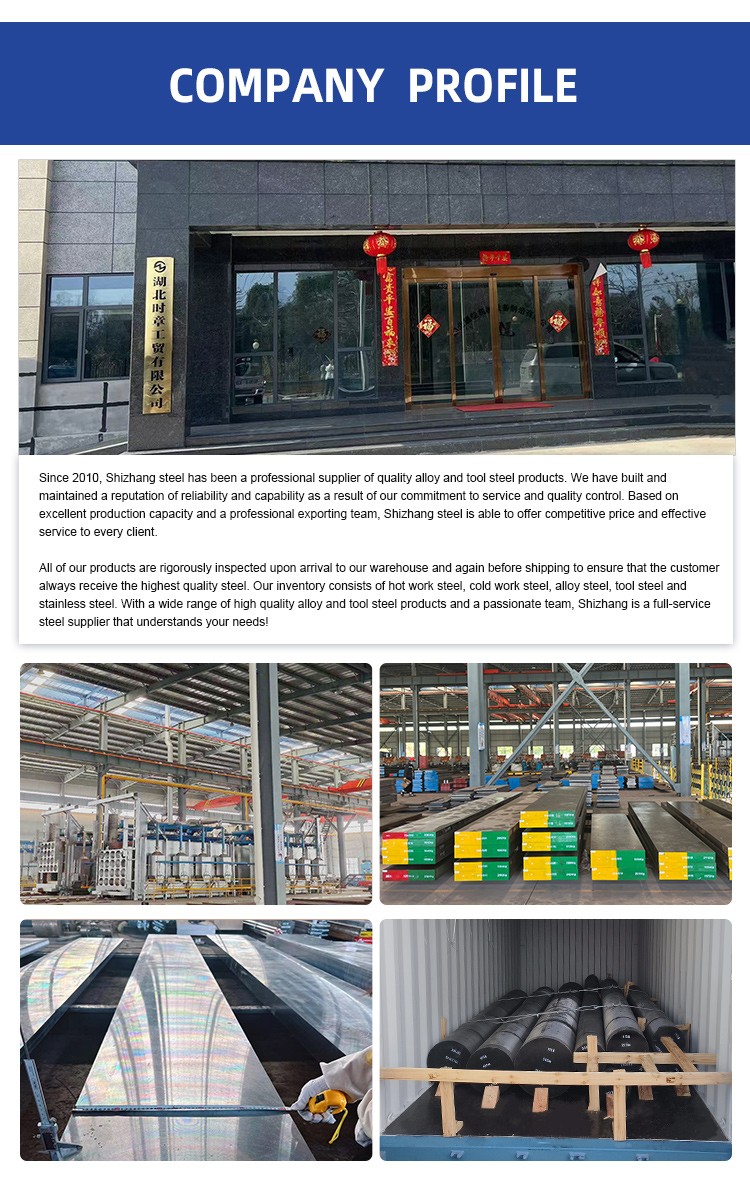

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

SKS93 high-speed tool steel, Japan's Hitachi constant-type oil steel series, is an improved steel type SK-3. Because the manganese and chromium and other ingredients are used to improve oil recovery and quenching, it can avoid quenching cracks and deformation that are easy to cause when ordinary high-carbon steel is quenched. It can obtain better sharpness and hardening ability (deeper hardening depth) than SK-3. Easy to process, with high hardness and wear resistance of general high carbon steel.

Product Name: COLD WORK DIE STEEL---SKS3

Similar steel grades:

U.S.A | ASTM O1 |

German | DIN 1.2510 |

Japan | JIS SKS3 |

Austria | - |

Sweden | - |

China | GB 9CrWMn |

Chemical composition:

Standard | C | Si | Mn | P | S | Cr | W |

JIS G4404:2000 | 0.9~1.0 | ≤0.35 | 0.9~1.2 | ≤0.030 | ≤0.030 | 0.5~1.0 | 0.5~1.0 |

Principal Feature:

SKS3 steel has high toughness, high hardness, air-cooling quenching and high chromium tool steel, which is better in hardness and toughness than SKD steel. SKS3 steel is vacuum refined and pure; the spheroidized annealing softens the structure for easy cutting and processing; it has high hardness during quenching; Good dimensional stability after tempering.

Typical Application:

SKS3 steel is widely used to make punching dies, stamping dies, bending dies, and finishing dies with a thickness of no more than 8mm; it is also widely used to make gauges, measuring tools, woodworking tools, lathe thimbles, etc.; it is also widely used to make Guide bushing, thimble, die, wire needle, etc.

Heat Treatment:

750℃~800℃ slow cooling

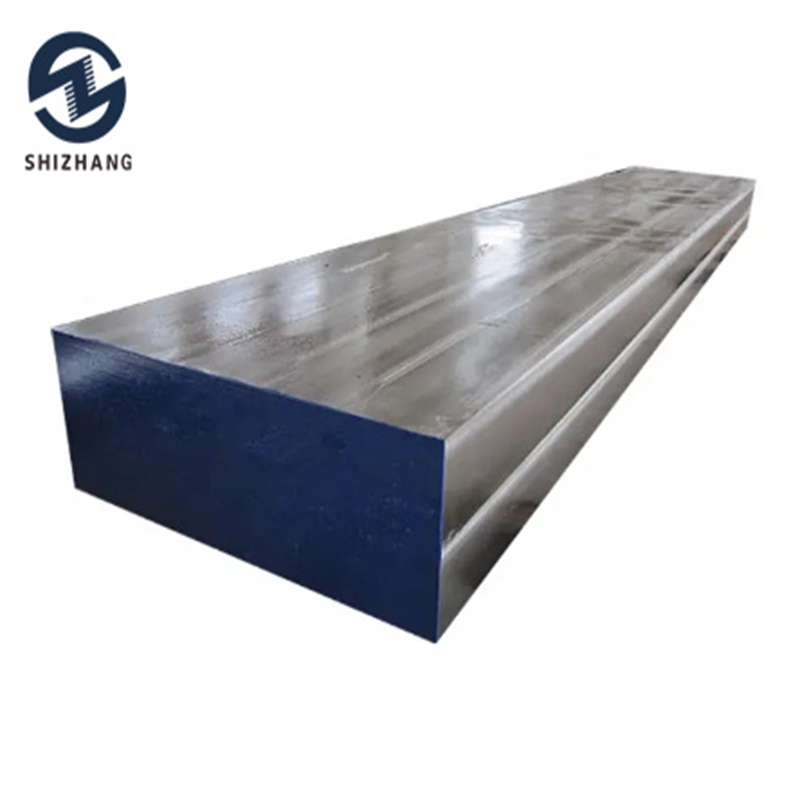

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |