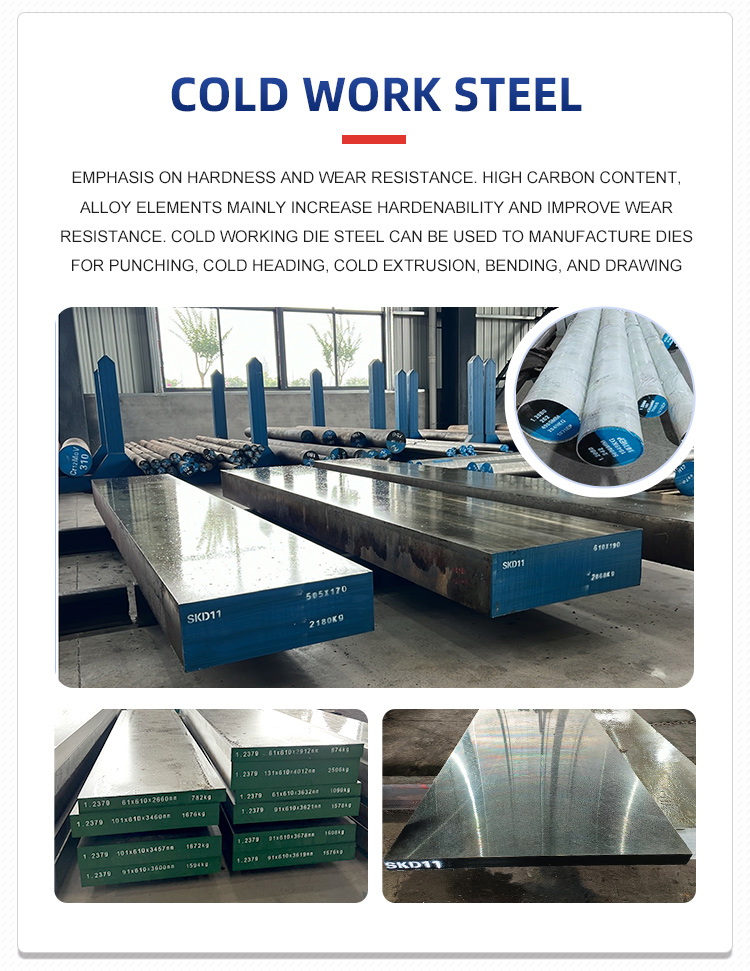

SKS31 Cold Work Die Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

SKS31 Cold Work Die Steel has high hardenability. Since tungsten forms carbides, this steel has more excess carbides and higher hardness and wear resistance than chromium steel and 9SiCr steel after quenching and low-temperature tempering. In addition, tungsten also helps preserve fine grains, giving the steel better toughness. Therefore, cutting tools made of SKS31 steel have less chipping and can better maintain the shape and size of the blade.Our company providesTool Steel Round Bar SKS31 and SKS31 cold work die steel plate for tool

Product Name: COLD WORK DIE STEEL---SKS31

Similar steel grades:

U.S.A | ASTM O7 |

German | DIN 1.2419 |

Japan | SKS31 |

Austria | - |

Sweden | - |

China | CrWMn |

Chemical composition:

Standard | C | Si | Mn | P | S | Cr | W |

JIS G4404:2000 | 0.95-1.05 | ≤0.35 | 0.9-1.2 | ≤0.030 | ≤0.030 | 0.8-1.2 | 1-1.5 |

Principal Feature:

SKS31 Cold Working Die Steel has high hardenability. Since tungsten forms carbides, this steel has more excess carbides and higher hardness and wear resistance than chromium steel and 9SiCr steel after quenching and low-temperature tempering. In addition, tungsten also helps preserve fine grains, giving the steel better toughness. Therefore, cutting tools made of SKS31 steel have less chipping and can better maintain the shape and size of the blade.

Typical Application:

SKS31 steel is used to make tools whose cutting edges do not heat up violently during work and measuring tools and cutting tools that require no deformation during quenching, such as making knives, long taps, long reamers, special milling cutters, die and other types of special tools , and tools for cutting soft non-metallic materials.

Heat Treatment:

750℃~800℃ slow cooling

Size available:

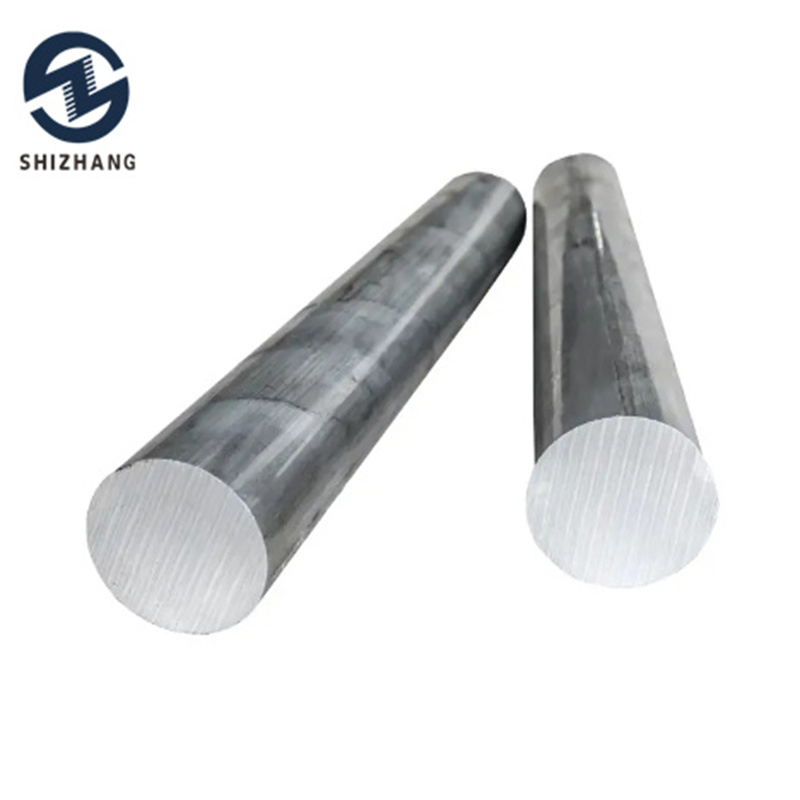

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |