SKD1 Cold Work Die Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

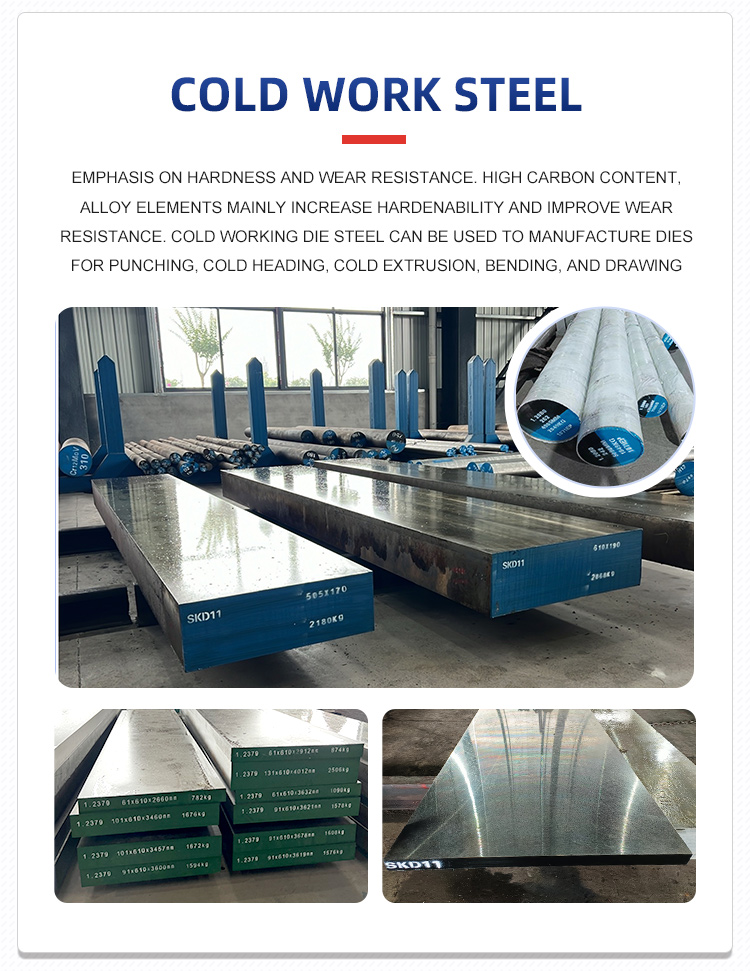

American High Carbon High Austenitic Steel SKD1,The types of supplies include hot-rolled materials, cold-drawn materials, forged materials, hot-rolled steel plates, and cold-drawn steel wires.Our company provides SKD1 Forged steel Alloy Round Bar and SKD1 steel plates

Product Name: COLD WORK DIE STEEL---SKD1

Similar steel grades:

U.S.A | ASTM D3 |

German | X210Cr12 /1.2080 |

Japan | SKD1 |

Austria | - |

Sweden | - |

China | Cr12 |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | V |

JIS G4404 | 1.90~2.20 | 0.10~0.60 | 0.20~0.60 | ≤0.030 | ≤0.030 | 11.0~13.0 | ≤0.030 |

Principal Feature:

Hitachi Metals SKD1 is the cold work die steel with the best wear properties. The heat treatment effect is stable. Steel for cold forging die steel for drawing dies... Resistance welding electrode: chromium zirconium copper ensures performance through a combination of heat treatment and cold working. , it can obtain the best mechanical properties and physical properties. High carbon, high chromium ledeburite cold work die steel with good hardenability and good wear resistance.

Typical Application:

American High Carbon High Austenitic Steel SKD1 is used to manufacture cold work dies and punches that are subject to small impact loads and require high wear resistance. Characteristics and scope of application: It is a widely used cold work die steel with high strength, good hardenability and good wear resistance, but poor impact toughness. It is mainly used for cold punching dies and punches, cold cutting scissors, drill sleeves, gauges, wire drawing dies, stamping dies, thread rolling dies, drawing dies and thread rolling dies that bear small impact loads and require high wear resistance. It can also be used as a general-purpose resistance welding electrode, mainly as an electrode for spot welding or seam welding of mild steel and coated steel plates. It can also be used as an electrode handle, shaft and gasket material for welding mild steel, or as a convex electrode. Large molds and fixtures for welding machines, molds or inlaid electrodes for stainless steel and heat-resistant steel.

Heat Treatment:

Starting temperature 1000°C. Final flame temperature 800°C;Quenching temperature 950~1000°C, oil cooling or air cooling

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |