Hot Work Tool Steel SKD62

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

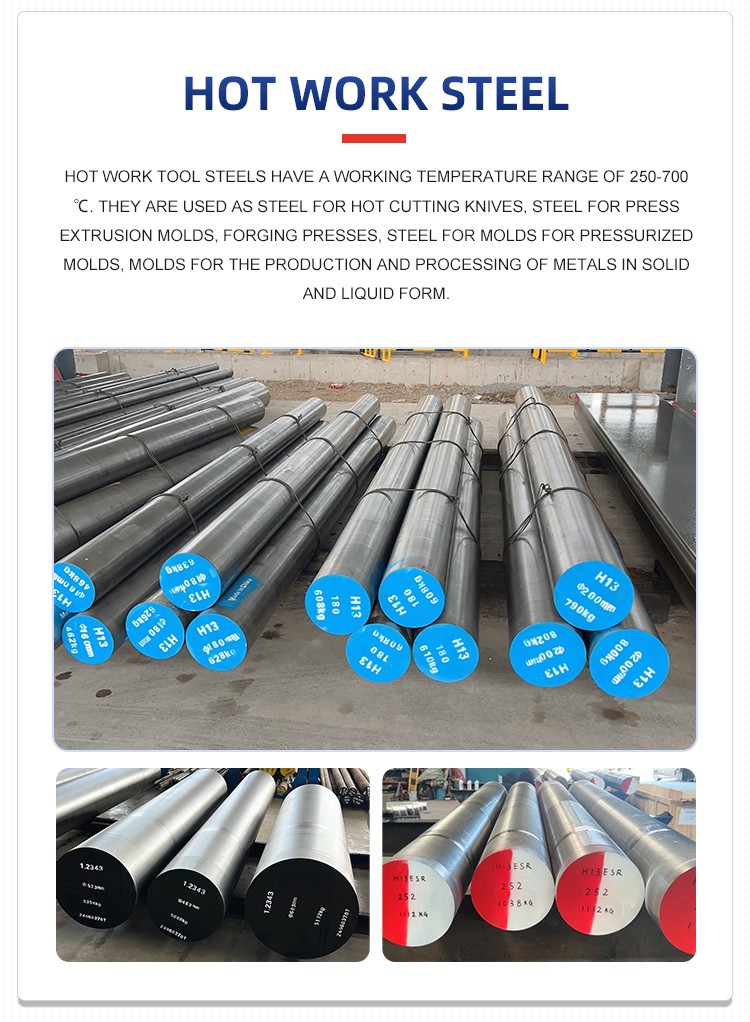

Hot Work Die Steel SKD62 is an air-cooled hardening hot work die steel with good hardenability, good thermal strength, oxidation resistance, high toughness and wear resistance at medium temperatures, good cold and heat fatigue resistance, and processing properties, heat treatment properties and polishing properties.Our company provides SKD62 Steel Round Bar and SKD62 steel plates

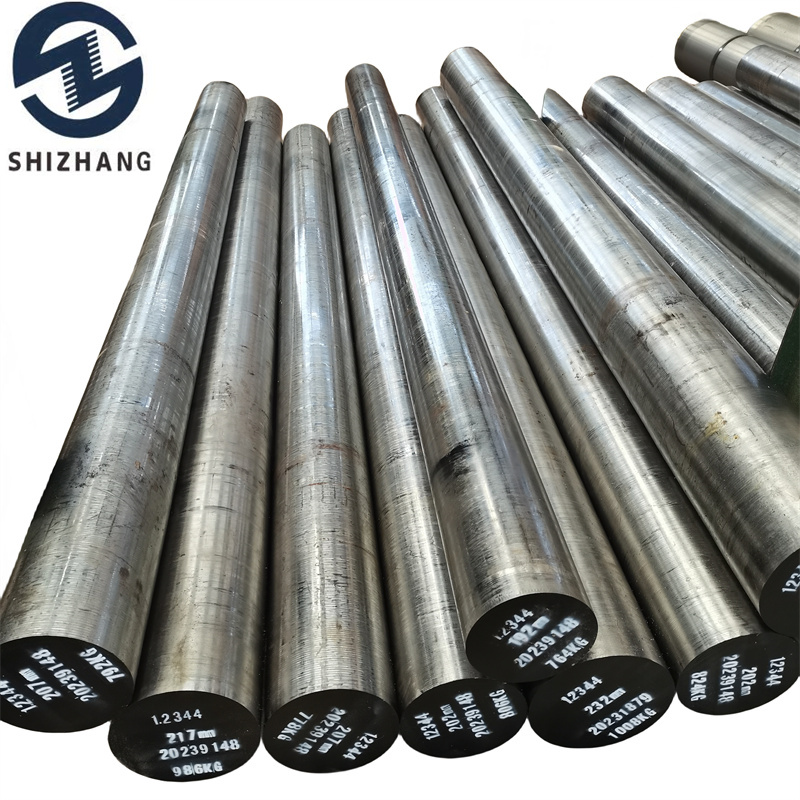

Product Name:HOT WORK DIE STEEL---SKD62

Similar steel grades:

U.S.A | ASTM H12 |

German | - |

Japan | SKD62 |

Austria | - |

Sweden | - |

China | - |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | Mo | W | V |

JIS G4404 -2000 | 0.32-0.4 | 0.8-1.2 | 0.2-0.5 | ≤0.020 | ≤0.030 | 4.75-5.5 | 1-1.6 | 1-1.6 | 0.2-0.5 |

Principal Feature:

SKD62 Steel is an air-cooled hardening hot work die steel with good hardenability, good thermal strength, oxidation resistance, high toughness and wear resistance at medium temperatures, good cold and heat fatigue resistance, and processing properties, heat treatment properties and polishing properties.

Typical Application:

SKD62 is suitable for high-speed forging dies, aluminum-magnesium alloy hot forging dies, etc. It can withstand the corrosion effects of aluminum, magnesium, and zinc and rapid changes in heat, and is suitable for manufacturing hot forging castings and reamers for aluminum, magnesium, and zinc alloy die-casting dies. , rolling knives, grooving knives, scissors and hot forging punches, etc. Aluminum and zinc die-casting molds are the most widely used steel materials.

Heat Treatment:

820℃~870℃ slow cooling.

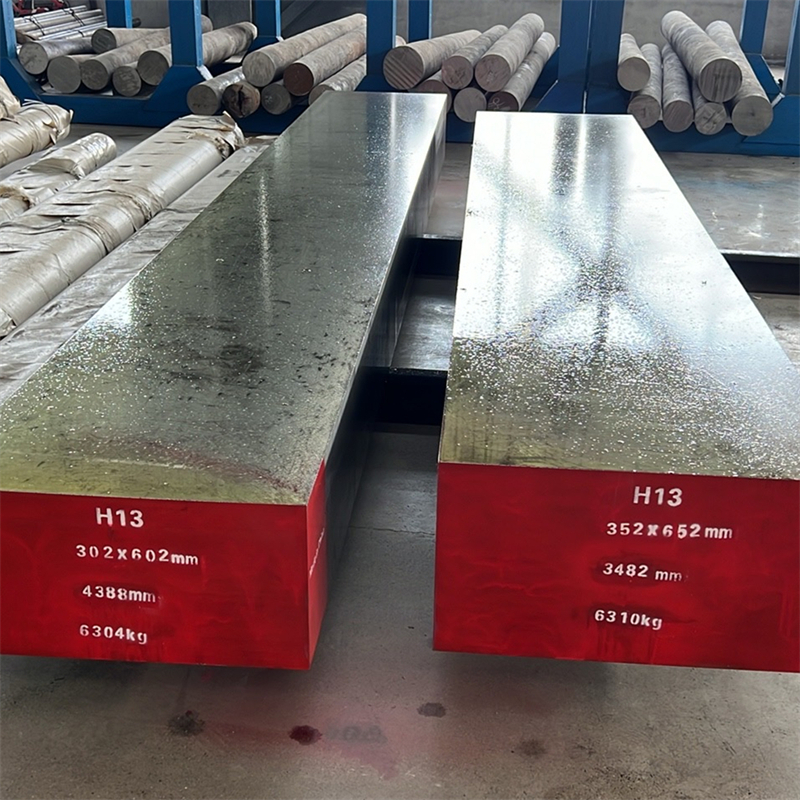

Size available:

Bars | Turned | Dia 12-505mm |

Black | Dia 12-505mm | |

Flats | Milled | T: 10-800 W: 210-1000mm |

Black | T: 10-800 W: 210-1000mm |