Cr8Mo2SiV Cold Work Tool Steel

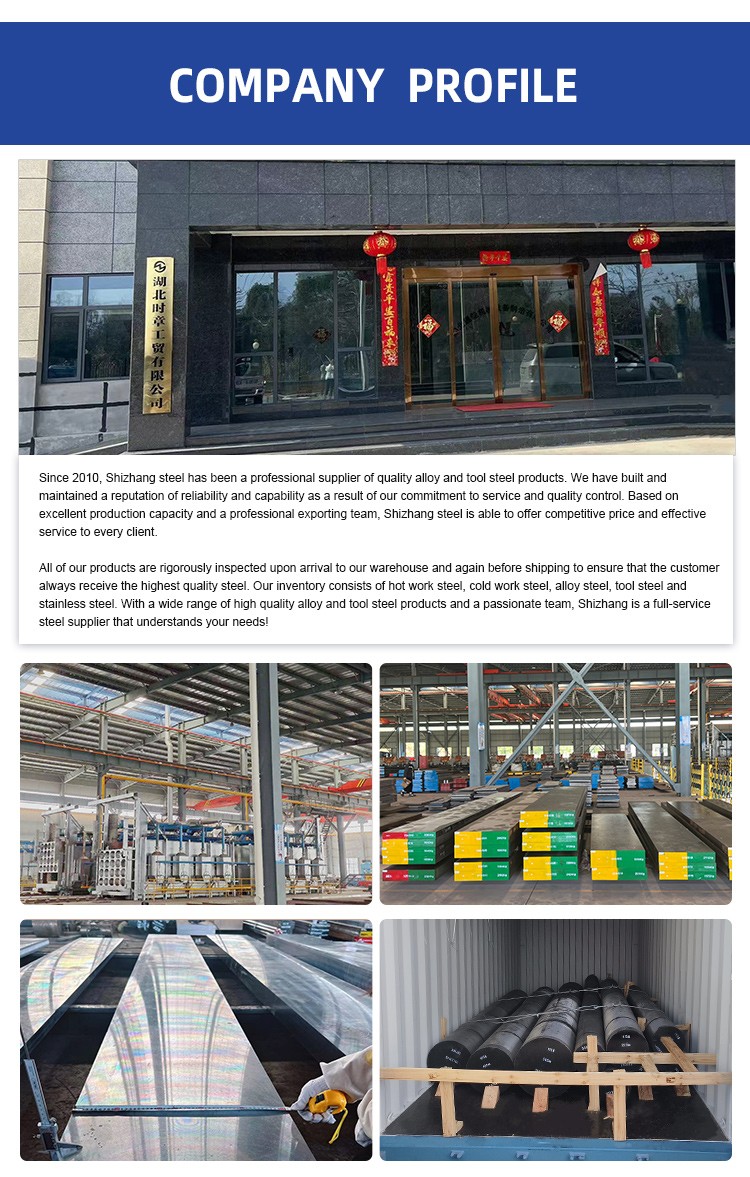

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

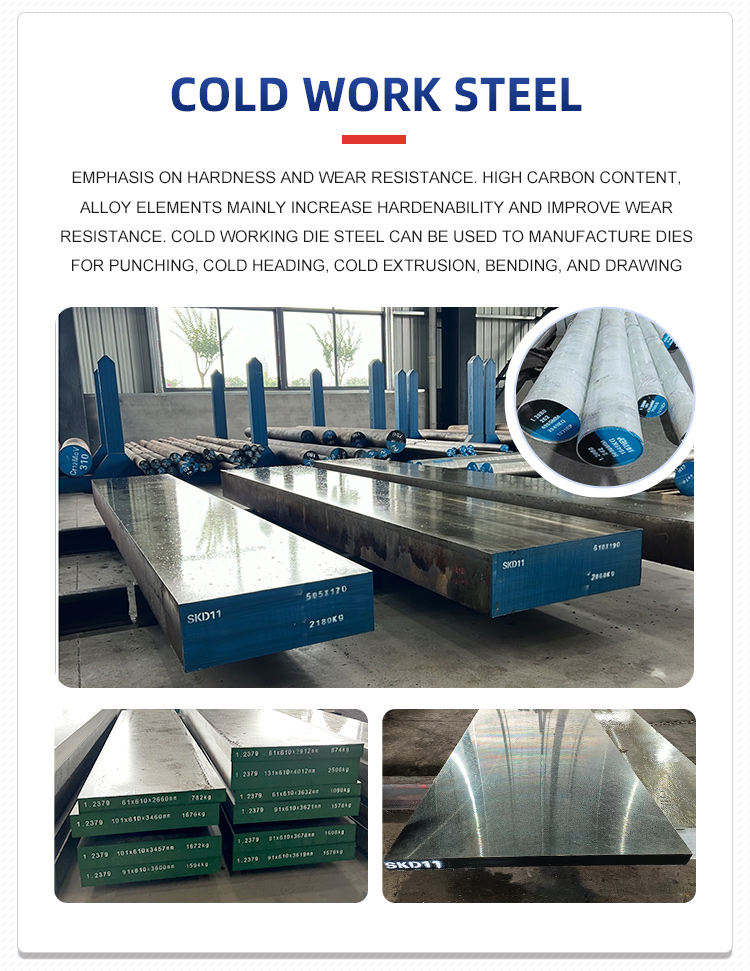

Cr8Mo2SiV series high carbon medium chromium cold work die steel, which is a new tool steel designed and developed on the basis of SKD11 high-carbon high-chromium ledeburite cold-working die steel. Its characteristic is to inhibit the formation of ledeburite eutectic by reducing the content of carbon and chromium.Our company provides 4Cr3Mo3SiV steel strip, 4Cr3Mo3SiV wire, 4Cr3Mo3SiV forged rod, etc.

Product Name: COLD WORK DIE STEEL---Cr8Mo2SiV

Similar steel grades:

U.S.A | - |

German | 1.2360 |

Japan | DC53 |

Austria | - |

Sweden | - |

China | Cr8Mo2SiV |

Chemical composition:

Standard | C | Si | Mn | P | S | Cr | Mo | V |

GBT 1299-2014 | 0.95-1.03 | 0.80-1.20 | 0.20-0.50 | ≤0.03 | ≤0.03 | 7.80--8.30 | 2.00~2.80 | 0.25-0.40 |

Principal Feature:

Cr8Mo2SiV series high carbon medium chromium cold work die steel, which is a new tool steel designed and developed on the basis of SKD11 high-carbon high-chromium ledeburite cold-working die steel. Its characteristic is to inhibit the formation of ledeburite eutectic by reducing the content of carbon and chromium. The formation of crystals is the fine, uniform and small amount of M7C3 carbide precipitation, which improves the plastic toughness and obtains excellent plasticity-toughness coordination. This steel is a martensitic steel type containing a small amount of excess primary carbides. At the same time, the steel has increased Mo content. After high-temperature tempering, it can obtain higher hardness and strength than SKD11. Panchang Steel adopts the process route of EF+LF+VD smelting 3t steel ingots → rough rolling → rolling flat steel to trial-produce Cr8Mo2SiV.

Typical Application:

Cr8Mo2SiV steel is used to manufacture hot work molds, die-casting molds, plastic molds, injection molds, etc., especially suitable for manufacturing large molds and parts. It has good heat resistance, wear resistance and hardness, and can maintain stable performance in high temperature, high pressure and high load working environments.

Heat Treatment:

960℃-980℃ or 1020℃-1040℃ oil cooling

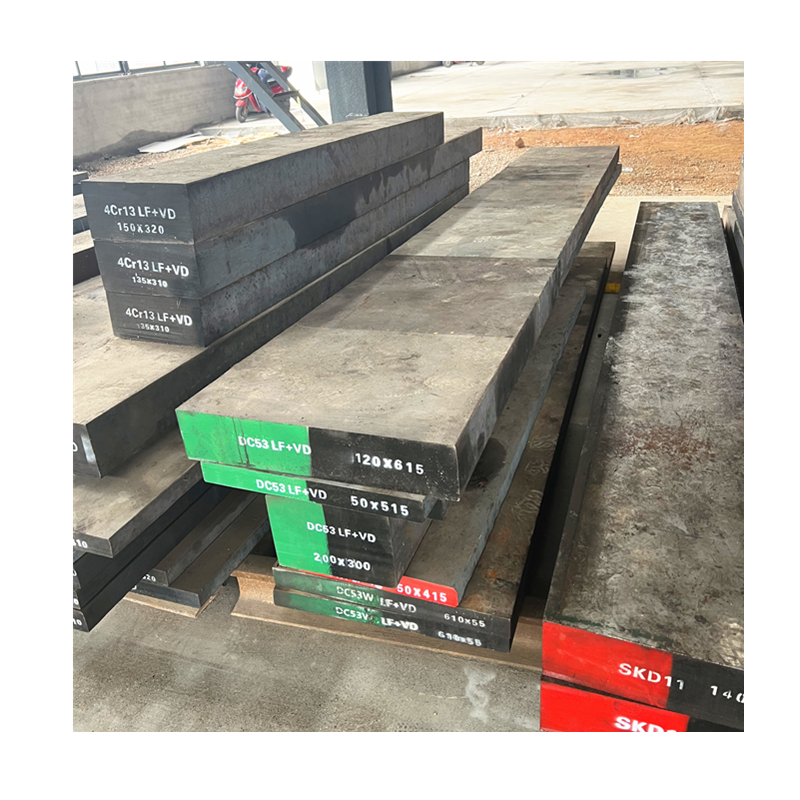

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |