Cr5Mo1V Cool Work Mold Steel

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

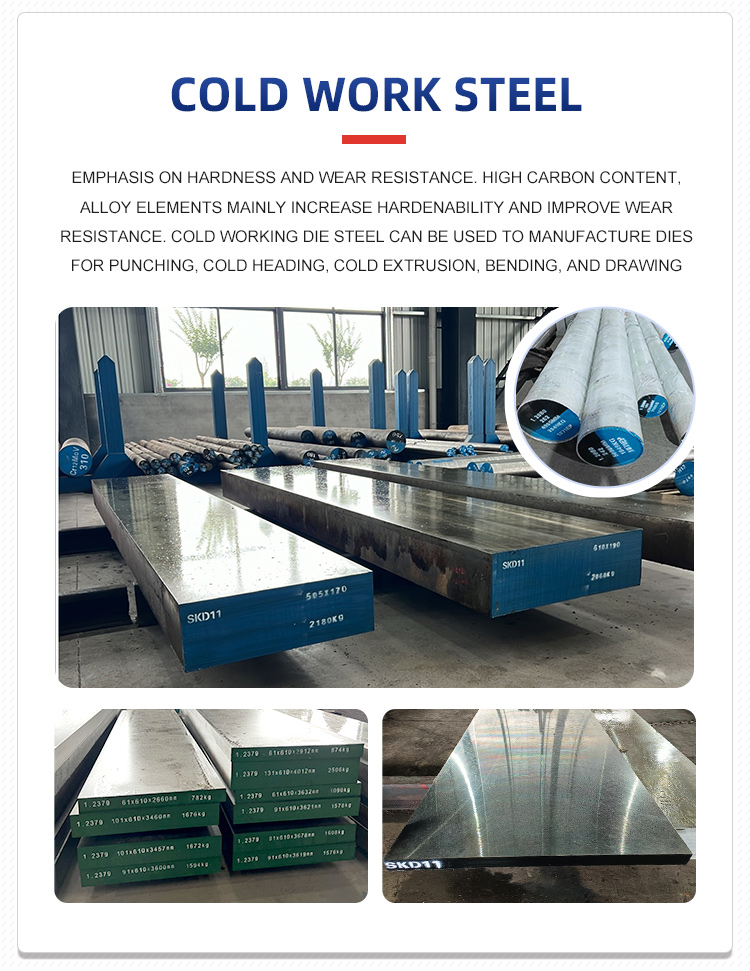

Cr5Mo1V is a air-quenching mold steel with deep air-quenching hardening properties, which is extremely beneficial for complex molds that require that their shape must be maintained after quenching and tempering. The deformation of this steel due to air quenching is only about 1/4 of that of manganese-containing oil-quenched tool steel. Its wear resistance is between manganese type and high carbon and high chromium type tool steel. Its toughness is better than any other type, especially Suitable for tools that require good wear resistance and special toughness.Our company provides Cr5Mo1V steel round bar and Cr5Mo1V mould steel plate

Product Name: COLD WORK DIE STEEL---Cr5Mo1V

Similar steel grades:

U.S.A | ASTM A2 |

German | DIN 1.2363 |

Japan | SKD12 |

Austria | - |

Sweden | - |

China | Cr5Mo1V |

Chemical composition:

Standard | C | Si | Mn | P | S | Cr | Mo | V |

GB/T1299-2014 | 0.95~1.05 | ≤0.50 | ≤1.00 | ≤0.030 | ≤0.030 | 4.75-5.50 | 0.90-1.40 | 0.15-0.50 |

Principal Feature:

Cr5Mo1V is a air-quenching mold steel with deep air-quenching hardening properties, which is extremely beneficial for complex molds that require that their shape must be maintained after quenching and tempering. The deformation of this steel due to air quenching is only about 1/4 of that of manganese-containing oil-quenched tool steel. Its wear resistance is between manganese type and high carbon and high chromium type tool steel. Its toughness is better than any other type, especially Suitable for tools that require good wear resistance and special toughness.

Typical Application:

Cr5Mo1V Cool Work Mold Steel is widely used in blanking dies and forming dies, rolls, punches, calendering dies and thread rolling dies, and is also used in some types of shear blades.

Heat Treatment:

Preheating at 790℃±15℃, heating at 940℃ (salt bath) or 950℃ (furnace controlled atmosphere) ±6℃, holding for 5min to 15min oil cooling; tempering once at 200℃±6℃, 2h

Size available:

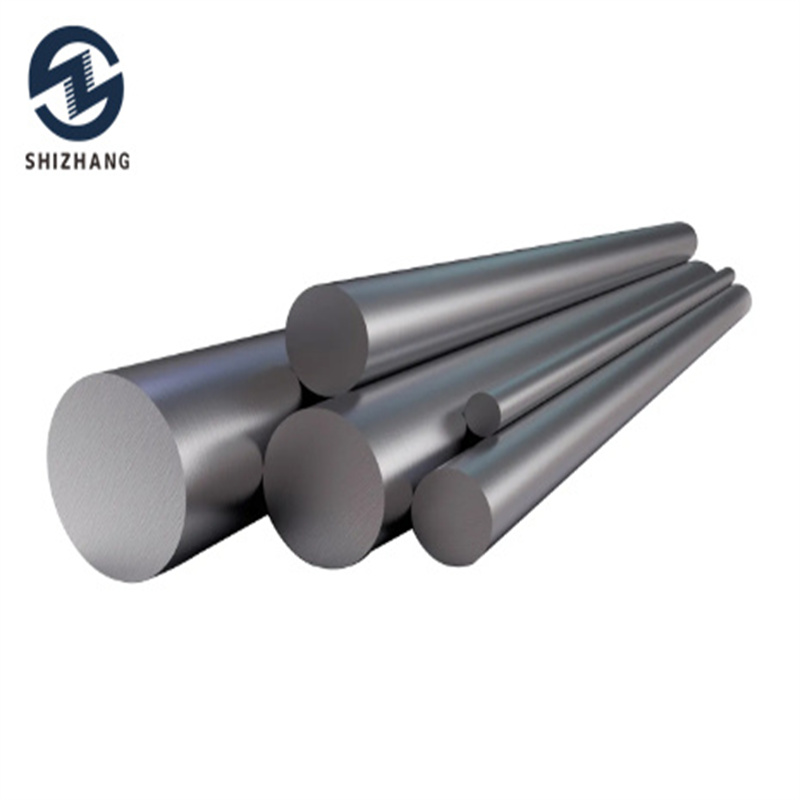

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

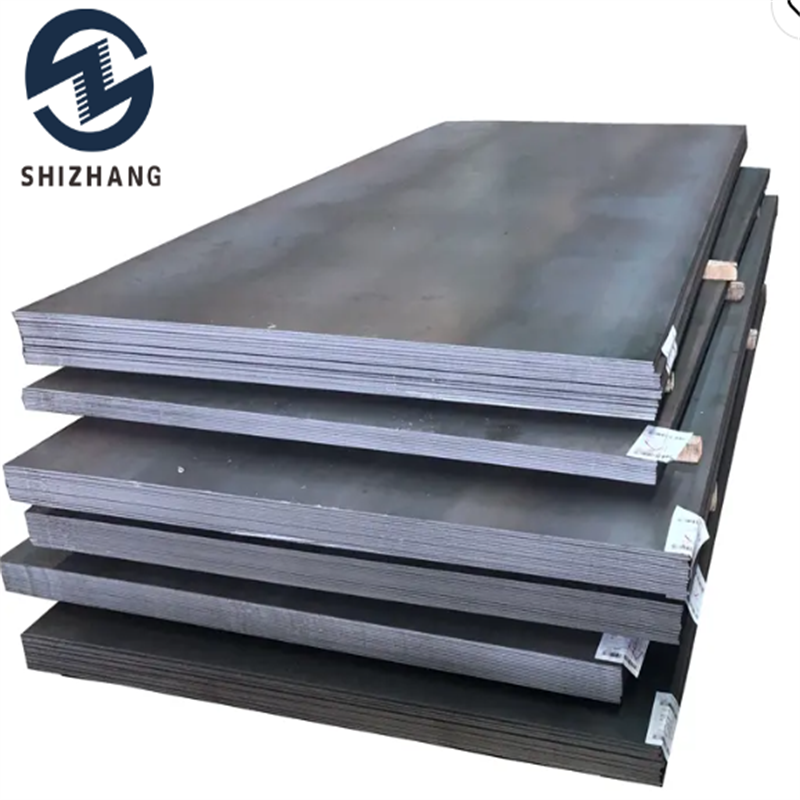

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |