Cold Work Die Steel Cr4W2MoV

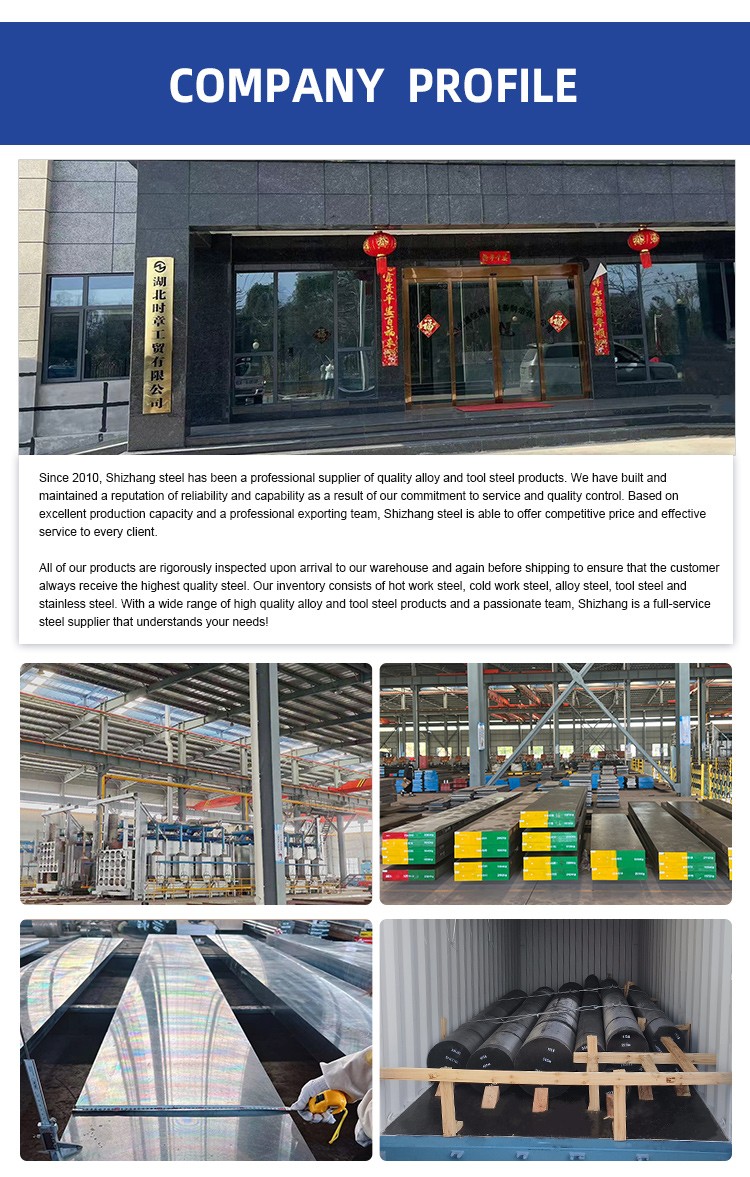

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

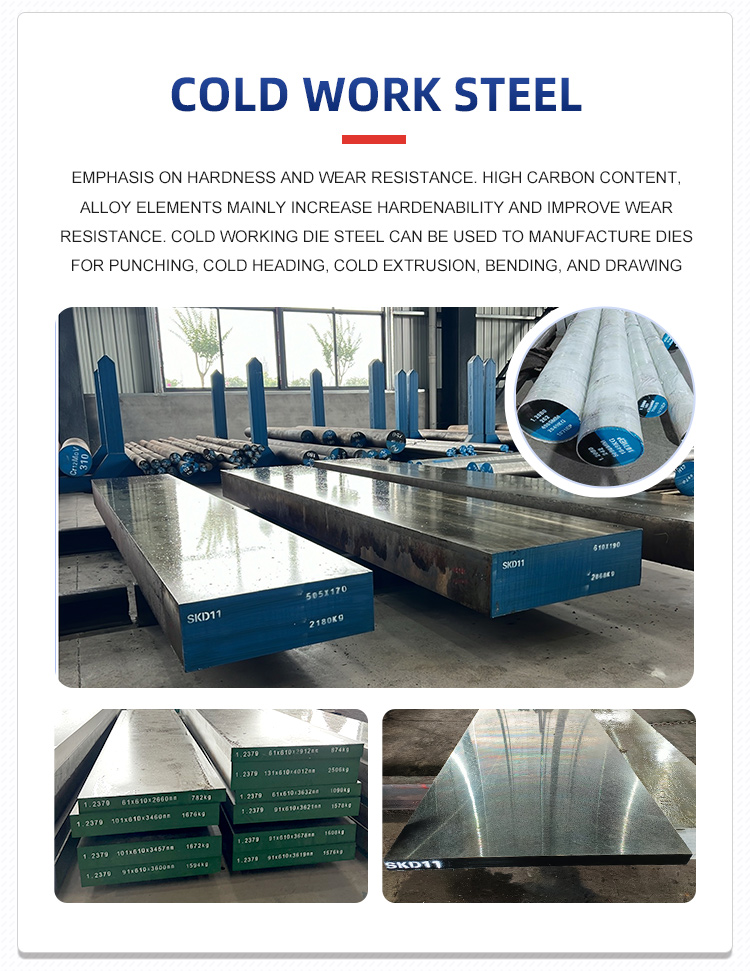

Cr4W2MoV cold work die steel has high alloy tool steel and a high wear-resistant, micro-deformation . It is a new type of alloy cold work die steel independently developed in my country. This steel is a substitute steel developed to address the shortcomings of Cr12 series steel.Our company provides Carbon Round Steel Rod Cr4W2MoV or 4Cr4W2MoV hot-rolled materials and 4Cr4W2MoV forged materials.

Product Name: COLD WORK DIE STEEL---Cr4W2MoV

Similar steel grades:

U.S.A | - |

German | - |

Japan | - |

Austria | - |

Sweden | - |

China | Cr4W2MoV |

Chemical composition:

Standard | C | Si | Mn | P | S | Cr | W | Mo | V |

GBT 1299-2014 | 1.12-1.25 | 0.40-0.70 | ≤0.4 | ≤0.03 | ≤0.03 | 3.5-4.0 | 1.9-2.6 | 0.80-1.20 | 0.8-1.10 |

Principal Feature:

Cr4W2MoV mold steel is a new type of mold steel developed to address the shortcomings of Cr12 steel. The Cr content is 2/3 less than that of Cr12 steel. It is a high-carbon, medium-chromium mold steel. Compared with Cr12 mold steel, the carbide particles are fine and evenly distributed. It has high hardenability and hardenability, equivalent wear resistance, small quenching deformation, and good dimensional stability. Cr4W2MoV steel is a high alloy tool steel and a high wear-resistant, micro-deformation cold work die steel. It is a new type of alloy cold work die steel independently developed in my country. This steel is a substitute steel developed to address the shortcomings of Cr12 series steel. It has good wear resistance and secondary hardening ability. The eutectic carbide particles of this steel are small and evenly distributed, and have high hardenability and hardenability, as well as good wear resistance and dimensional stability.

Typical Application:

Cr4W2MoV mold steel is mainly used to replace Cr12 mold steel to manufacture various punch dies, cold forging dies, blanking dies, cold extrusion dies and wire rolling plates, etc., and can increase the life of the mold.

Heat Treatment:

960℃-980℃ or 1020℃-1040℃ oil cooling

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |