Cold Work Die Steel 7CrSiMnMoV

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

7CrSiMnMoV is Flame quenched cold work die steel,7CrSiMnMoV is New low alloy air cooled hardened steel,7CrSiMnMoV steel has good hardenability and can be hardened by air cooling. Its hardness can reach HRC62~64 and has small deformation after air cooling and quenching. This steel not only has high strength but also has excellent toughness.It has the advantages of easy operation, low cost and energy saving.Our company provides7CrSiMnMoV Alloy Steel Round Bar Rod etc.

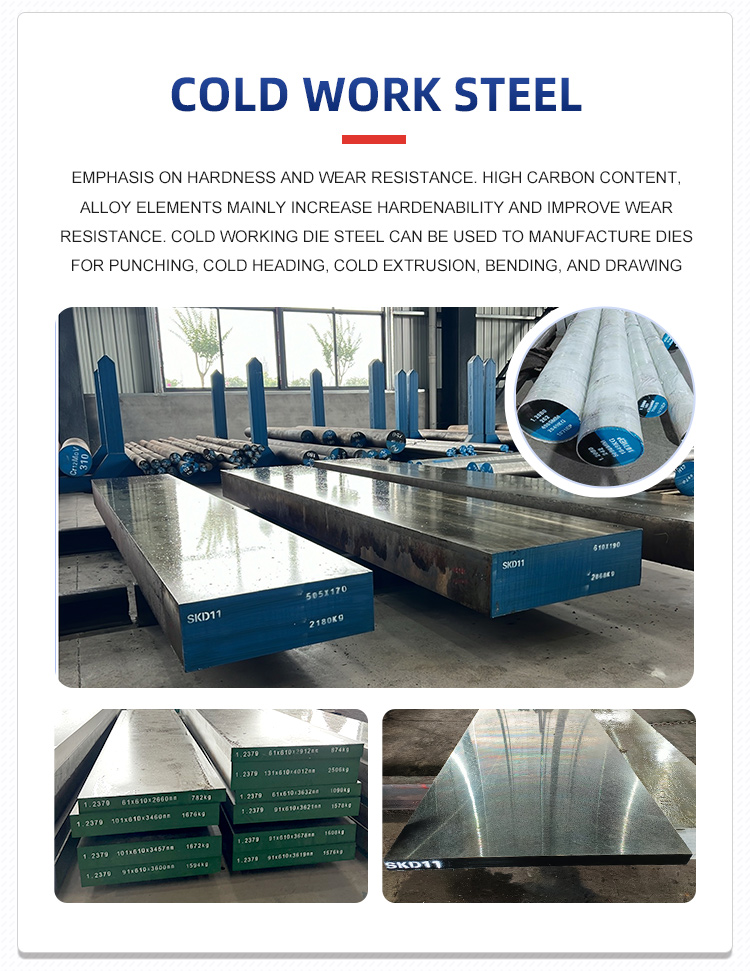

Product Name: COLD WORK DIE STEEL---7CrSiMnMov

Similar steel grades:

U.S.A | - |

German | - |

Japan | JIS CH-1 |

Austria | - |

Sweden | - |

China | 7CrSiMnMoV |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | Mo | V |

GB/T1299-2014 | 0.65-0.75 | 0.85-1.15 | 0.65-1.05 | ≤0.030 | ≤0.030 | 0.90-1.20 | 0.20~0.50 | 0.15~0.30 |

Principal Feature:

7CrSiMnMoV steel has good hardenability and can be hardened by air cooling. Its hardness can reach HRC62~64 and has small deformation after air cooling and quenching. This steel not only has high strength but also has excellent toughness.It has the advantages of easy operation, low cost and energy saving.

Typical Application:

7CrSiMnMoV steel is suitable for making cutting tools. For example: twist drill, broach, tapping, milling cutter, cutting knife, reamer, etc. It can be used in cutting when hot hardness requirements are not high.

Also suitable for cold room applications; for example for punching, forming, stamping, and others. Manufacturing various high-speed cutting tools and cold and hot molds.

Heat Treatment:

870℃-900℃ oil cooling or air cooling, 150℃±10℃ tempering air cooling.

Size available:

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |