6CrW2Si Tool Steel

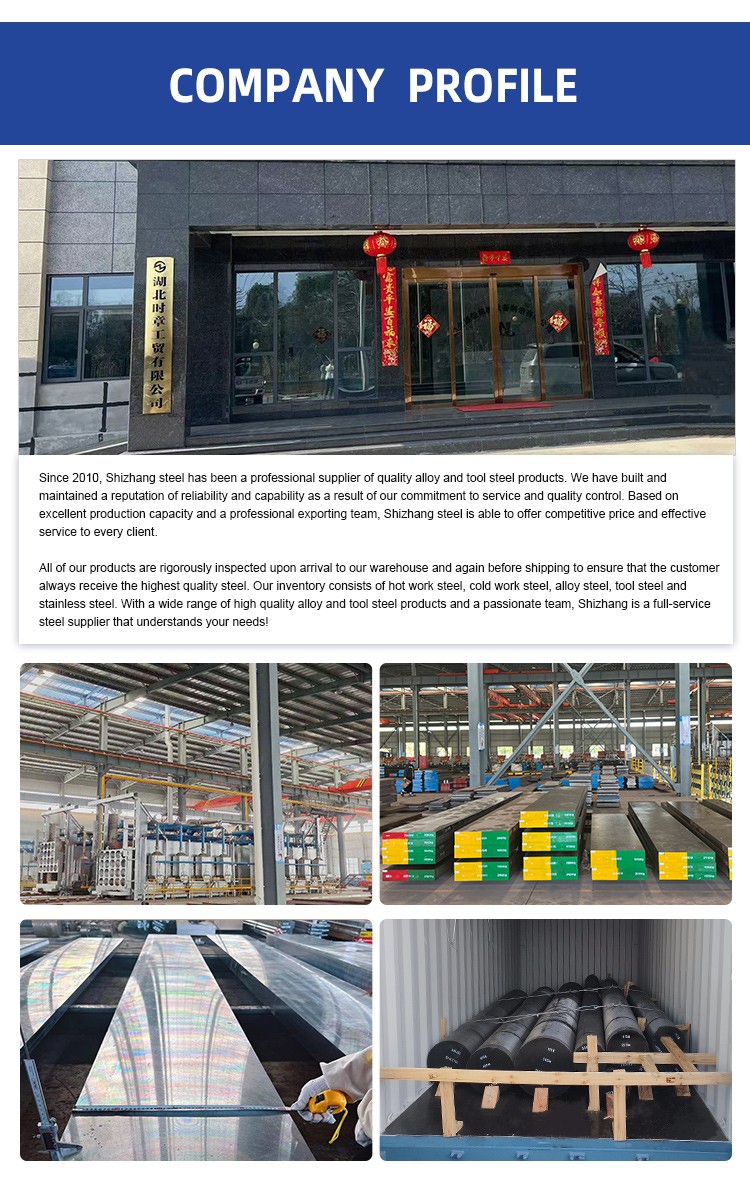

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

6CrW2Si has excellent wear resistance, toughness and hardness. Its high hardness and high toughness enable it to maintain the cutting performance of the tool during high-speed cutting, while also resisting the risk of wear and fracture. In addition, 6CrW2Si also has good thermal properties Stability and corrosion resistance, able to work stably in high temperature, high pressure and corrosive environmentsl ,we can provide 6CrW2Si round bar、6CrW2Si steel plate and so on.

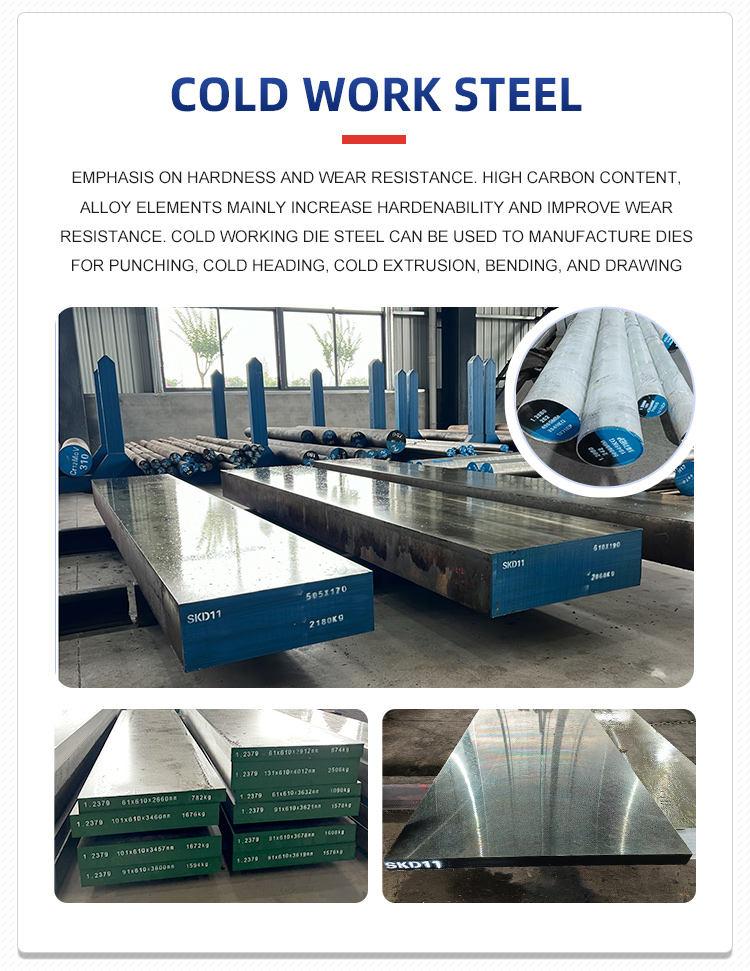

Product Name: COLD WORK DIE STEEL---6CrW2Si

Similar steel grades:

U.S.A | - |

German | 60WCrv7 |

Japan | - |

Austria | - |

Sweden | 2550 |

China | 6CrW2Si |

Chemical composition:

Standard | C | Si | Mn | Cr | W | P | S |

GB/T1299—2000 | 0.55~0.65 | 0.50~0.80 | ≤0.40 | 1.00~1.30 | 2.00~2.70 | ≤0.030 | ≤0.030 |

Principal Feature:

6CrW2Si alloy steel has excellent wear resistance, toughness and hardness. Its high hardness and high toughness enable it to maintain the cutting performance of the tool during high-speed cutting, while also resisting the risk of wear and fracture. In addition, 6CrW2Si also has good thermal properties Stability and corrosion resistance, able to work stably in high temperature, high pressure and corrosive environmentsl.

Typical Application:

Special steel 6CrW2Si has higher quenching hardness and certain high-temperature strength than 4CrW2Si steel and 5CrW2Si steel. Usually used to manufacture tools that withstand impact loads and require high wear resistance, such as pneumatic tools, chisels and stamping dies, cold shear blades, punching dies, air hammer tools, etc.

Heat Treatment:

Samples are quenched at 860~900℃ and oil cooled

Size available:

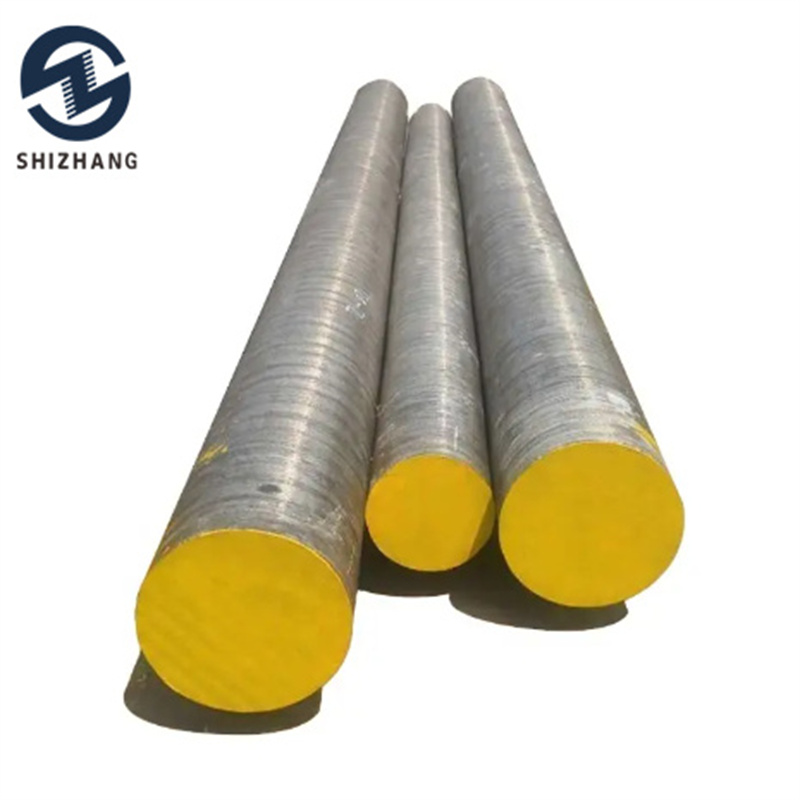

Bars | Turned | Dia 20-500mm |

Black | Dia 20-500mm | |

Flats | Milled | T: 8-300 W: 210-610mm |

Black | T: 8-300 W: 210-610mm |