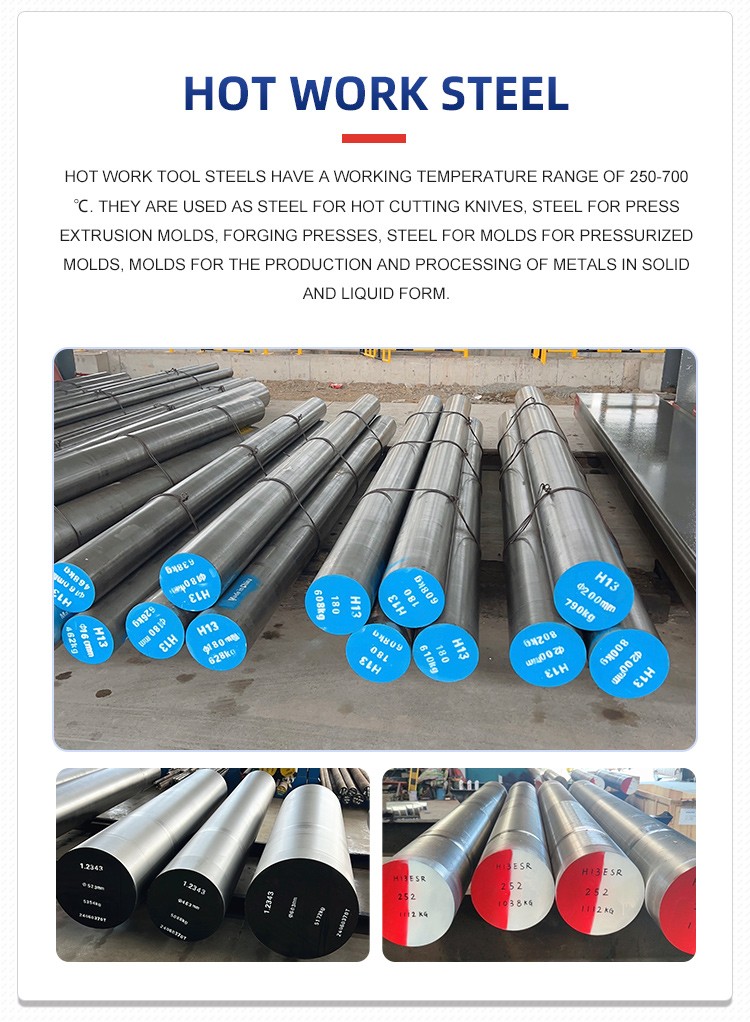

4Cr5MoSiV1 Hot Work Mold Steel

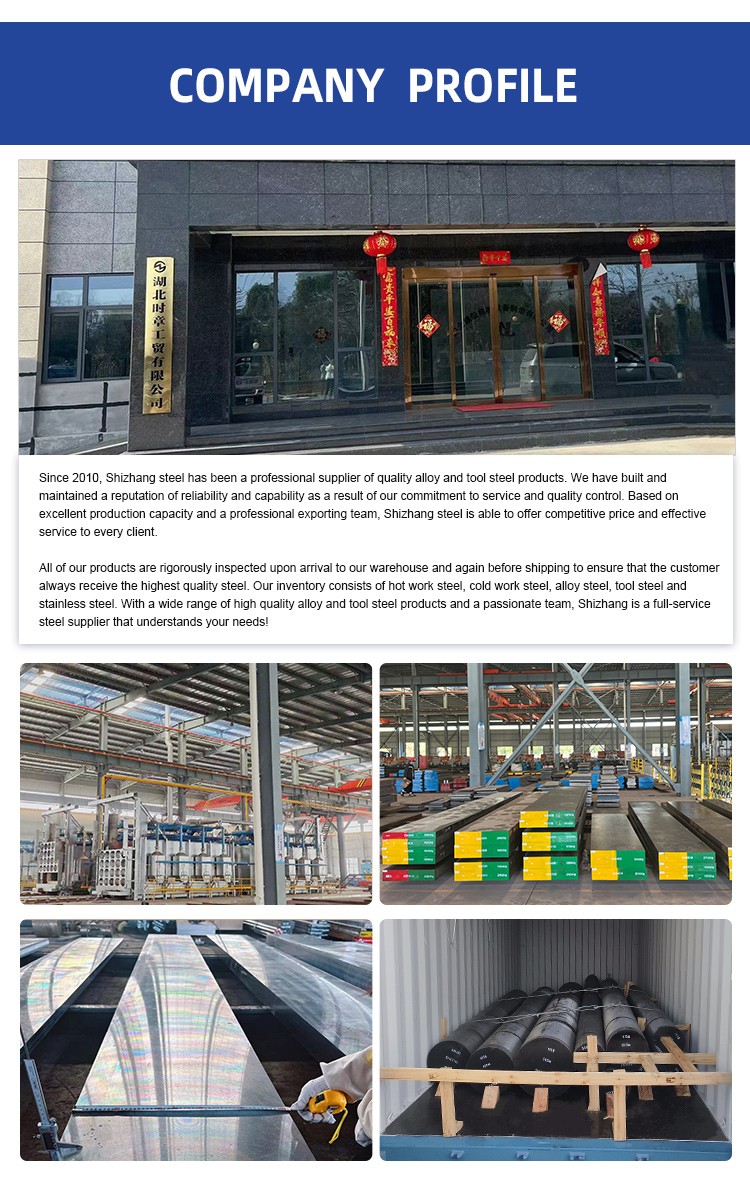

- Shizhang Steel

- China

- 15-45days

- 500 Tons/Month

4Cr5MoSiV1 Hot Work Mold Steel is a high-quality tool steel material with high hardness, excellent cutting stability, wear resistance, heat treatment stability and thermal conductivity. It plays an important role in the manufacturing of various cold work molds and cutting tools, meeting the needs for high strength, high hardness and high wear resistance.The corresponding foreign brand of 4Cr5MoSiV1 is SKD61、1.2344、H13

Product Name: HOT WORK TOOL STEEL---4Cr5MoSiV1

Similar steel grades:

U.S.A | H13 |

German | 1.2344 |

Japan | SKD61 |

Austria | - |

Sweden | - |

China | 4Cr5MoSiV1 |

Chemical composition:

Standard | C | Si | Mn | S | P | Cr | V | Mo |

GB/T 1299-1985 | 0.32~0.45 | 0.80~1.20 | 0.20~0.50 | ≤0.030 | ≤0.030 | 4.75~5.50 | 0.80~1.20 | 1.10~1.75 |

Principal Feature:

4Cr5MoSiV1 Steel is a high-quality tool steel material with high hardness, excellent cutting stability, wear resistance, heat treatment stability and thermal conductivity. It plays an important role in the manufacturing of various cold work molds and cutting tools, meeting the needs for high strength, high hardness and high wear resistance.

Typical Application:

Due to the excellent properties of 4Cr5MoSiV1, it is widely used in the manufacturing of cold work molds, dies, cutting tools and cutting edges. This material is often used to process cold, hard and brittle materials such as metal, plastic, rubber, etc. It is also widely used in industries such as automobiles, machinery manufacturing, electronics, plastic injection molding, etc.

Heat Treatment:

sample quenching, preheating at 790±15℃, heating at 1000±6℃ (salt bath) or 1010±6℃ (furnace controlled atmosphere), holding for 5~15min, air cooling, and tempering at 550±6℃.

Size available:

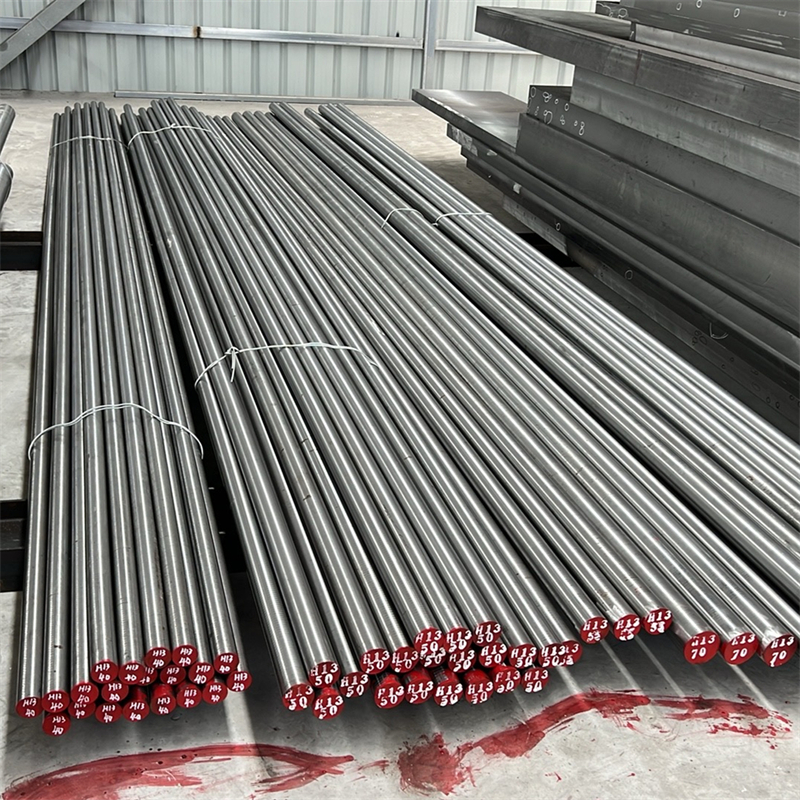

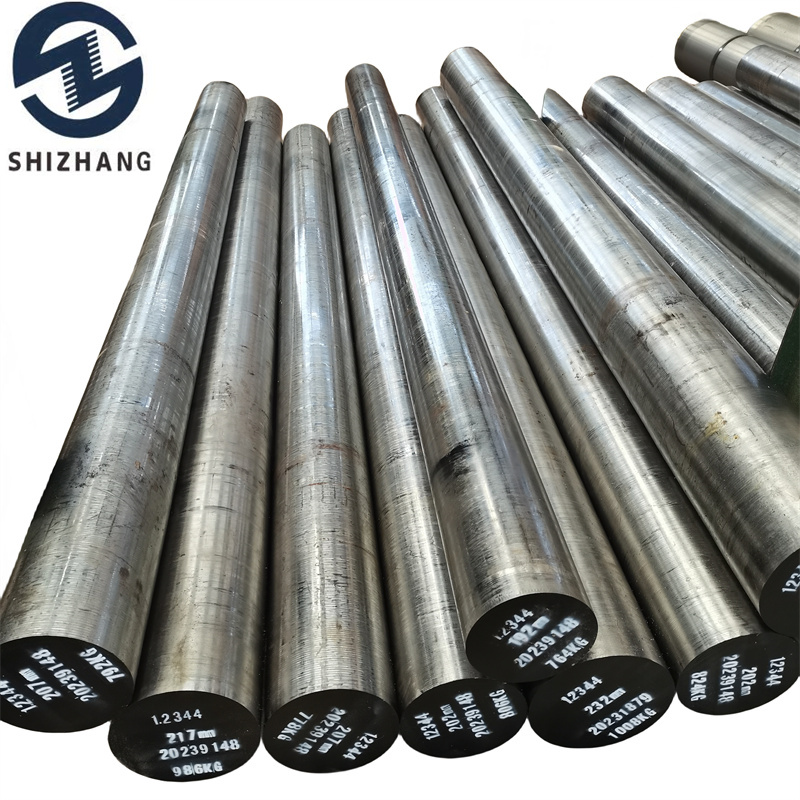

Bars | Turned | Dia 20-800mm |

Black | Dia 20-800mm | |

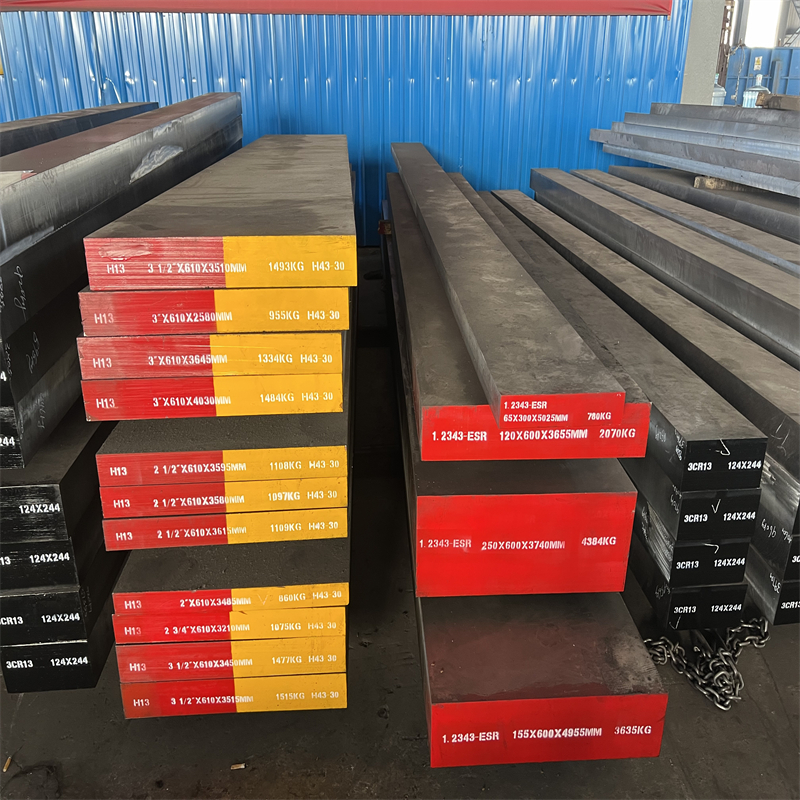

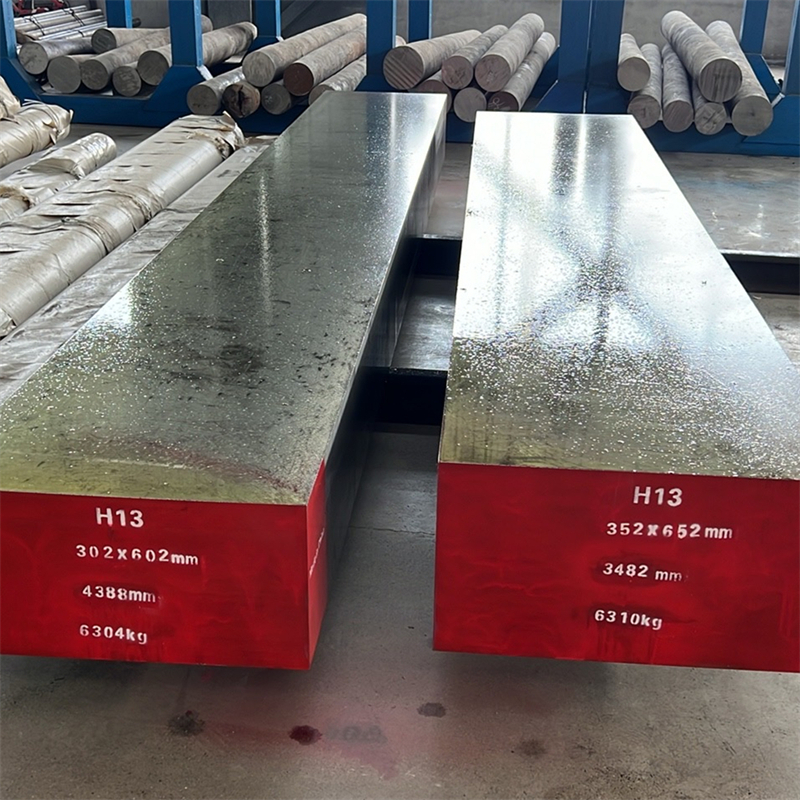

Flats | Milled | T:50-300 W: 200-710mm |

Black | T: 8-300 W: 200-710mm |