CNC Machining Parts

- China

- 15-45

- >3000 pcs

Our products such as cnc machining parts,casting parts,sheet metal stamping parts,forging parts,fasteners and plastic injection parts have been export to many countries like Kazakhstan,Russia, Germany, America and so on.

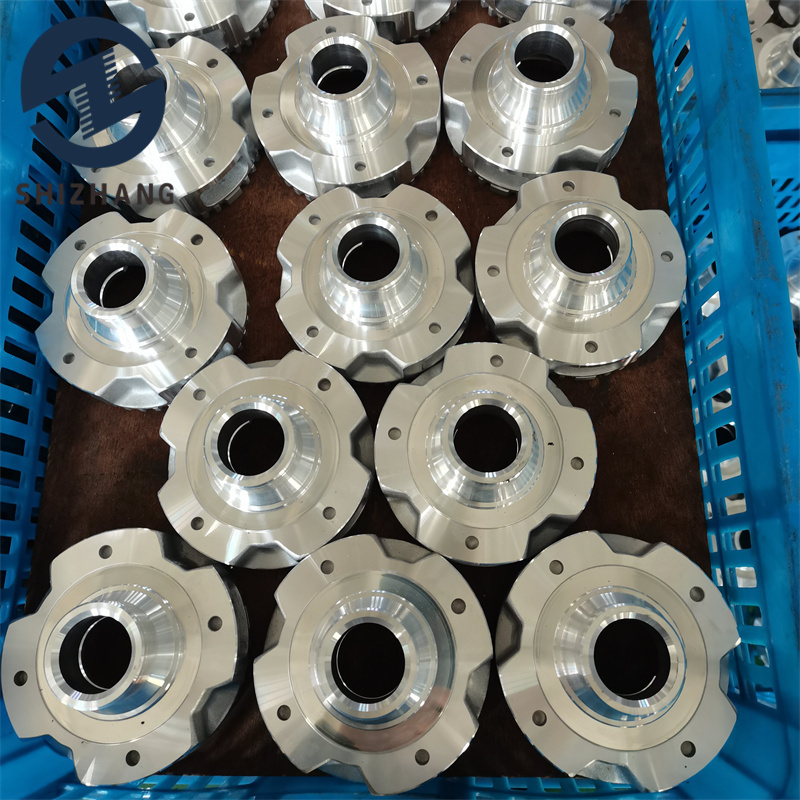

Product Name: CNC Machining Parts

Product Description

Tolerance | +/-0.005~+/-0.01mm |

Surface Roughness | Min Ra0.1~3.2 |

Drawing Accepted | Stp,Step,Igs,Xt,AutoCAD(DXF,DWG), PDF,or Samples |

Lead Time | 1-2 weeks for samples,3-4 weeks for mass production |

Quality Assurance | ISO9001:2015, SGS, RoHs, TUV |

Payment Terms | Trade Assurance, TT, Paypal, Western Union, LC |

1. Main Materials

Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416 etc. |

Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

Copper | C11000,C12000,C12000, C36000 etc. |

Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

Iron | A36, 45#, 1213, 12L14, 1215 etc. |

Plastic | ABS, PC, PE, POM, Nylon, PP, Peek etc. |

2.Surface Treatment

Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving |

Steel | Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated |

Aluminum parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing |

Plastic | Plating gold (ABS), Painting, Brushing (Acylic), laser engraving |

3. Application

Agricultural equipment | Armament | Automobile industry | Computing equipment |

Medical / dental instruments | Measuring instruments | Miscellaneous equipment | Pharmaceutical industry |

Orthopedic implants | Safety equipment | Petrochemical industry | Industrial valves |

Fixing and movable equipment | Sanitary fittings | General machinery | Pumps and general connections |

Food and beverage processing | Instrumentation equipment | Pharmaceutical industry | Textile equipment |

4.Technical Support

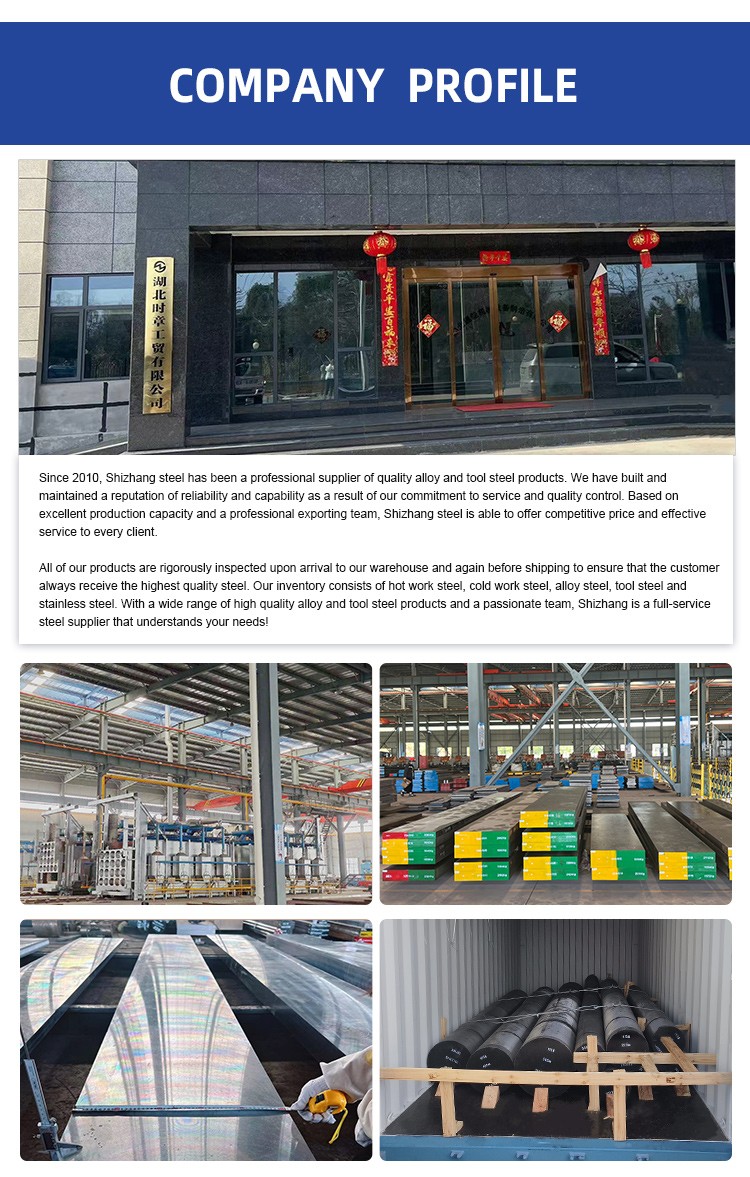

Factories that Shizhang steel deal with are professional at independent development and design. The engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID WORKS and other 2D & 3D software. They are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

5.Quality Control

1) Checking the raw material after they reach the factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)