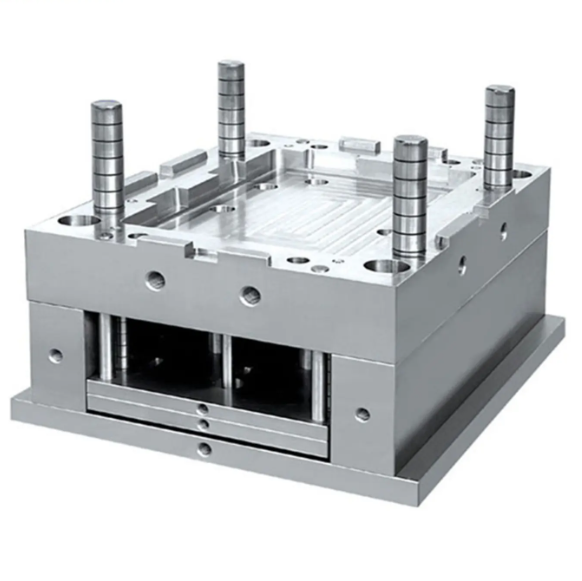

Applications of Plastic Mould Steel

Plastic mold steel, a crucial material in the manufacturing industry, finds extensive usage in the production of plastic parts and components. Its unique properties, including high hardness, excellent wear resistance, and thermal stability, make it an ideal choice for creating molds that can withstand the rigors of the plastic injection molding process. The application of plastic mold steel spans various industries, from automotive to electronics. In the automotive sector, it is used to produce intricate parts like dashboards and door panels, ensuring precise shapes and durable finishes. In electronics, the material is essential for creating housings and components that require high precision and repeatability. The use of plastic mold steel not only enhances the quality of the final product but also improves production efficiency. Its durability reduces the need for frequent mold replacements, while its precision ensures consistency in part dimensions. Additionally, the material's thermal stability helps maintain mold integrity during the heating and cooling cycles of the injection molding process. In conclusion, plastic mold steel is a versatile and reliable material that plays a pivotal role in the manufacturing of plastic parts. Its widespread application across various industries underscores its importance in meeting the demands of modern production processes.