Cold Work Tool Steel

-

SKD10 Ledeburite Cold Work Die Steel

SKD10 special steel is high carbon, high chromium type ledeburite cold work die steel, cobalt is not a required component unless there are special requirements. SKD10 mold steel has good hardenability, small heat treatment deformation, wear resistance and impact resistance

Email Details -

Cold Work Die Steel 7CrSiMnMoV

7CrSiMnMoV is Flame quenched cold work die steel,7CrSiMnMoV is New low alloy air cooled hardened steel,7CrSiMnMoV steel has good hardenability and can be hardened by air cooling. Its hardness can reach HRC62~64 and has small deformation after air cooling and quenching. This steel not only has high strength but also has excellent toughness.It has the advantages of easy operation, low cost and energy saving.Our company provides7CrSiMnMoV Alloy Steel Round Bar Rod etc.

Email Details -

AISI O2 Cold Work Tool Steel

O2 Steel is an oil hardening tool steel which is supplied in the annealed condition and characterised by its characteristics of offering good durability. O2 tool steel is with excellent wear resistance and its ability to hold a good cutting edge.

Email Details -

Cr8Mo2SiV Cold Work Tool Steel

Cr8Mo2SiV series high carbon medium chromium cold work die steel, which is a new tool steel designed and developed on the basis of SKD11 high-carbon high-chromium ledeburite cold-working die steel. Its characteristic is to inhibit the formation of ledeburite eutectic by reducing the content of carbon and chromium.Our company provides 4Cr3Mo3SiV steel strip, 4Cr3Mo3SiV wire, 4Cr3Mo3SiV forged rod, etc.

Email Details -

Cold Work Drawn Steel JIS SKS3

Cold Work Drawn Steel JIS SKS3 has high toughness, high hardness, air-cooling quenching and high chromium tool steel, which is better in hardness and toughness than SKD steel

Email Details -

SKS31 Cold Work Die Steel

SKS31 Cold Work Die Steel has high hardenability. Since tungsten forms carbides, this steel has more excess carbides and higher hardness and wear resistance than chromium steel and 9SiCr steel after quenching and low-temperature tempering. In addition, tungsten also helps preserve fine grains, giving the steel better toughness. Therefore, cutting tools made of SKS31 steel have less chipping and can better maintain the shape and size of the blade.Our company providesTool Steel Round Bar SKS31 and SKS31 cold work die steel plate for tool

Email Details -

SKD12 Advanced Cold Work Die Steel

Cold Work Drawn Alloy steel SKD12 has medium alloy content. Because it contains molybdenum and vanadium, it has good hardenability, uniform carbide distribution, certain impact toughness and good wear resistance. It has good air quenching performance, small dimensional deformation during air quenching, better toughness than 9Mn2V and Cr12, uniform and fine carbides, and good wear resistance.SKD12 is air quenching mold steel.

Email Details -

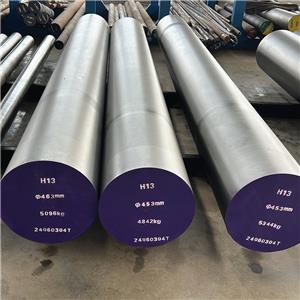

SKD2 High Carbon High Chromium Cold Work Die Steel

SKD2 cold work mold steel has high-carbon, high-chromium with excellent wear resistance and impact resistance. Its chemical composition and heat treatment process have an important impact on its performance.Our company provides SKD2 cold work die steel plate for tool and JIS SKD2 Cold Work Tool Steel Round Bar

Email Details -

9CrWMn Low Alloy Cold Work Die Steel

9CrWMn mold steel is low alloy cold work mold steel. This steel has certain hardenability and wear resistance, small quenching deformation, uniform carbide distribution and fine particles.Our company provides 9CrWMn round rods and 9CrWMn steel plates

Email Details